Center device used for multiple types of tape winding machines

A reeling machine, multi-model technology, applied in the direction of winding strips, transportation and packaging, thin material handling, etc., can solve inconvenience and other problems, and achieve the effect of reducing waste loss, huge social benefits, and shortening downtime.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

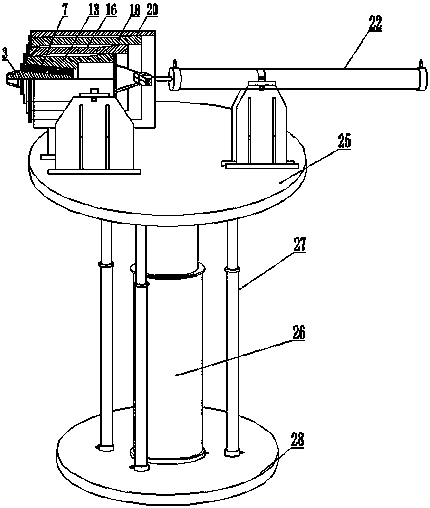

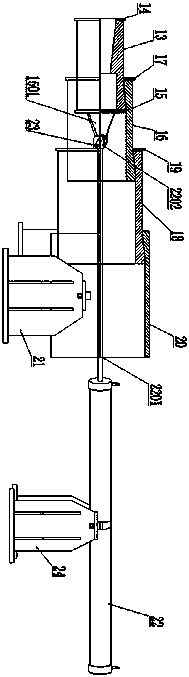

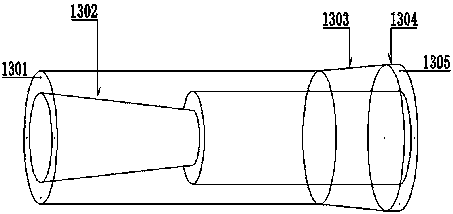

[0037] Such as figure 1 A top device for multi-model tape winding machines is shown, including a lifting unit, a horizontal telescopic unit and a top unit; the lifting unit is arranged below the horizontal telescopic unit, and the top unit is arranged on the horizontal telescopic unit.

[0038] The lifting unit includes a master cylinder 26, an auxiliary cylinder 27, a cylinder group top plate 25 and a cylinder group bottom plate 28;

[0039] Described master cylinder 26 and auxiliary cylinder 27 are vertically arranged, and auxiliary cylinder 27 is arranged in a triangle at the periphery of master cylinder 26; The axis and the center of the cylinder group top plate 25 are on the same axis; the bottom of the cylinder barrel of the main cylinder 26 and the auxiliary cylinder 27 is provided with a cylinder group bottom plate 28;

[0040] As a preference, the main cylinder 26 and the auxiliary cylinder 27 are single-acting cylinders; one main cylinder 26 is selected, and three a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com