Closed micro negative pressure air-floating separation device

A separation device, closed technology, applied in liquid separation, separation method, grease/oily substance/floating matter removal device, etc., can solve problems such as long running time, great influence of water quality and quantity fluctuations, unstable effluent water quality, etc. Achieve the effects of reducing operating costs, increasing removal efficiency, and reducing hazardous characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

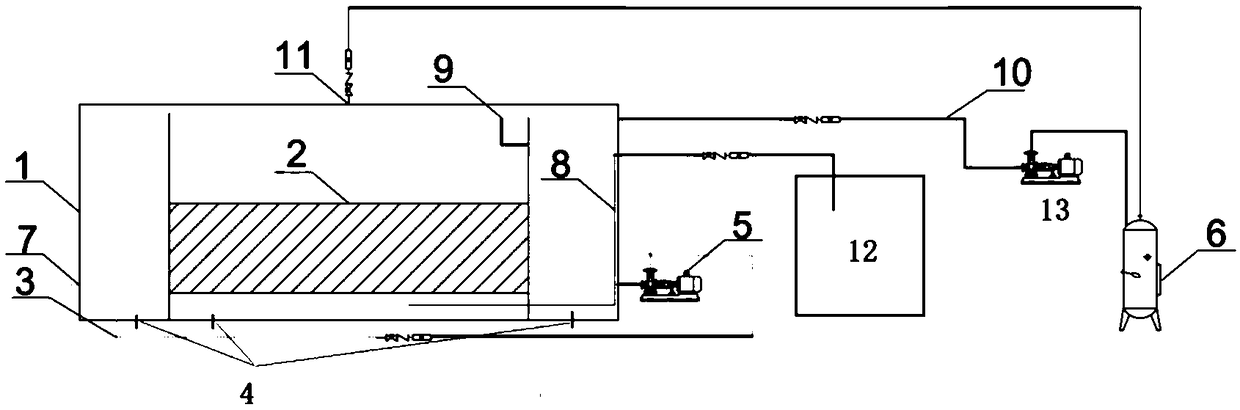

[0017] The technical solution is further described in conjunction with reference to the accompanying drawings, examples of the embodiments are shown in the accompanying drawings, wherein the same or similar reference numerals represent the same or similar elements or elements with the same or similar functions, but the description is only used It is used for explaining the present invention, but should not be construed as limiting the present invention.

[0018] See details figure 1 , a closed micro-negative pressure air flotation separation device provided by the present invention includes a tank body 1, an inclined plate 2, a return pipe 3, a sewage pipe 4, a first multiphase flow pump 5, a dissolved air tank 6, a water inlet pipe 7, Air flotation outlet pipe 8, scum collection tank 9, return gas output pipe 10, nitrogen input pipe 11, water collection tank 12, second multiphase flow pump 13; sewage discharge pipe 4 and water inlet pipe 7 are arranged at the lower part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com