A processing technology of special-shaped coated glass sheet

A technology of coated glass and processing technology, which is applied in glass production, glass manufacturing equipment, glass cutting devices, etc., can solve problems such as low positioning accuracy, film layer burning, and wave band instability, so as to improve production efficiency and quality, and ensure stability performance, improve the effect of yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

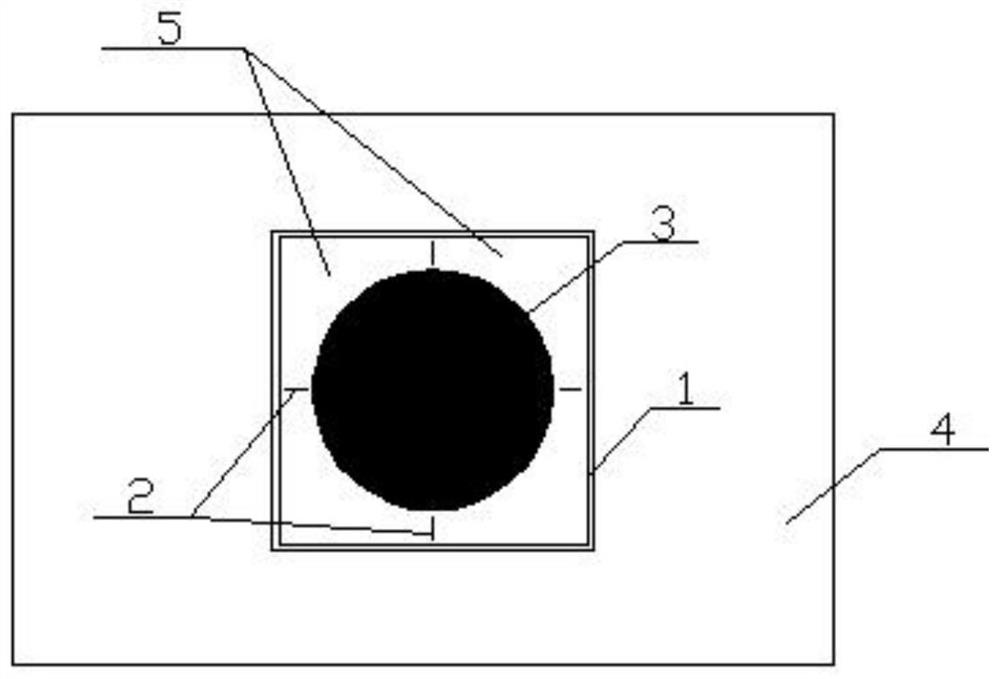

[0026] Embodiment 1 refers to figure 1 , the processing technology of a kind of special-shaped coated glass sheet of the present invention, comprises the following several steps: the first step, laser rapid cutting equipment cuts out special-shaped pattern 3 on glass sheet 4; A number of symmetrically distributed laser cutting leads 2 are cut out; in the third step, the laser rapid cutting equipment cuts out the frame 1 on the glass sheet 4; in the fourth step, the glass sheet 4 is cleaned, and the cleaned glass sheet 4 is placed Enter the coating equipment for coating; the fifth step, remove the special-shaped pattern 3 along the laser cutting lead 2 and frame 1, wherein the laser rapid cutting equipment is a picosecond laser that can emit a wavelength of 1050nm laser, and the frequency of the picosecond laser is 80kHz , the number of pulses of the picosecond laser is 5, the point pitch of the picosecond laser is 15 μm, the coating equipment is a coating sputtering machine, ...

Embodiment 2

[0027] Embodiment 2 refers to figure 1 , the processing technology of a kind of special-shaped coated glass sheet of the present invention, comprises the following several steps: the first step, laser rapid cutting equipment cuts out special-shaped pattern 3 on glass sheet 4; A number of symmetrically distributed laser cutting leads 2 are cut out; in the third step, the laser rapid cutting equipment cuts out the frame 1 on the glass sheet 4; in the fourth step, the glass sheet 4 is cleaned, and the cleaned glass sheet 4 is placed Enter the coating equipment for coating; the fifth step, remove the special-shaped pattern 3 along the laser cutting lead 2 and frame 1, wherein the laser rapid cutting equipment is a picosecond laser that can emit a wavelength of 1070nm laser, and the frequency of the picosecond laser is 40kHz , the number of pulses of the picosecond laser is 3, the point pitch of the picosecond laser is 8 μm, the coating equipment is a coating sputtering machine, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com