Sewing machine pneumatic lifting electronic mop mechanism and control method thereof

A pneumatic lifting and sewing machine technology, which is applied in the direction of sewing machine control devices, sewing machine components, sewing equipment, etc., can solve the problems such as insufficient response of mop wheel mop cloth, failure to meet low-end customers, driven shaft and synchronous belt breakage, etc. Achieve the effect of improving mop congestion, simple structure, and reducing the phenomenon of needle loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below in conjunction with accompanying drawing:

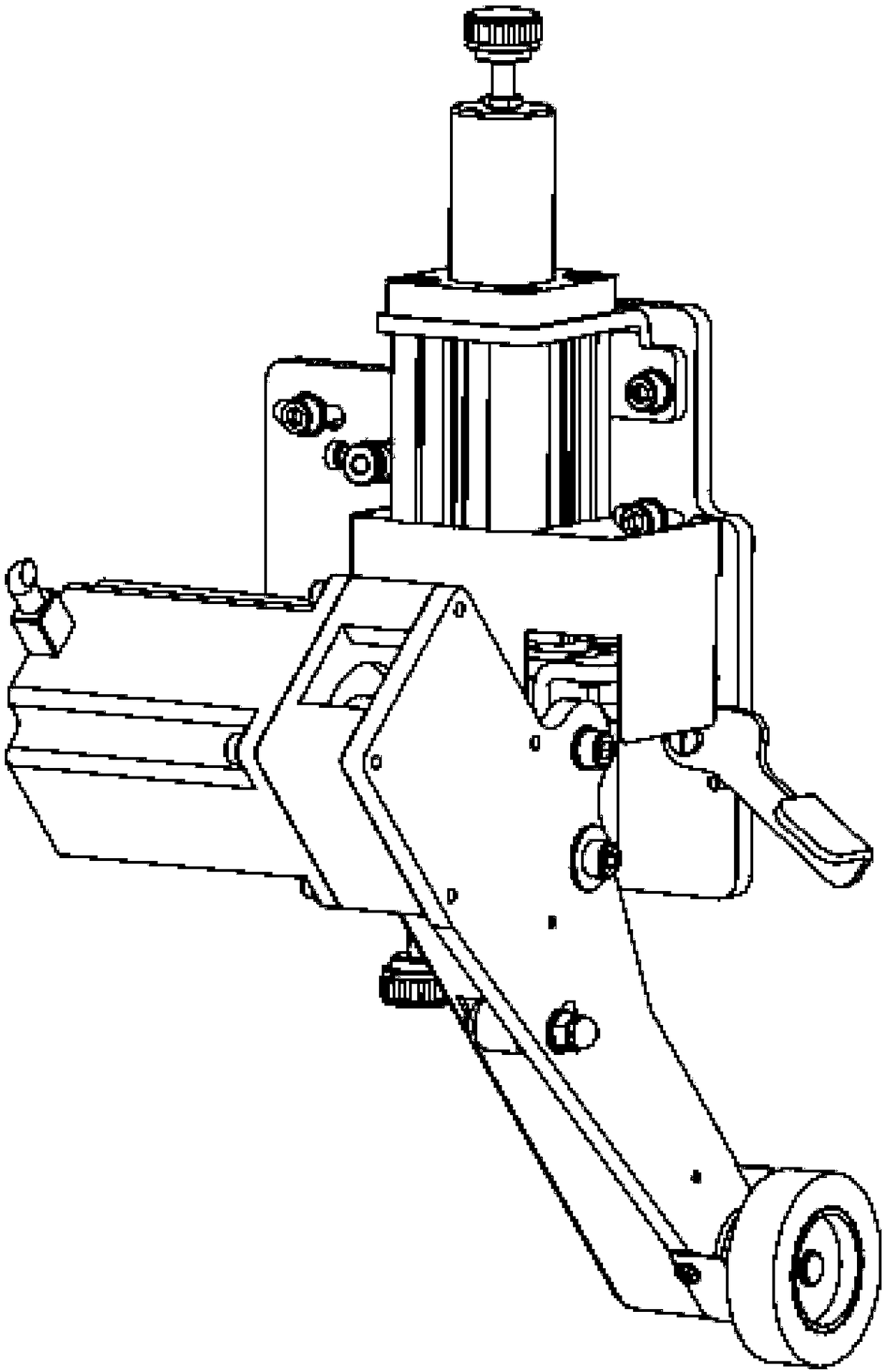

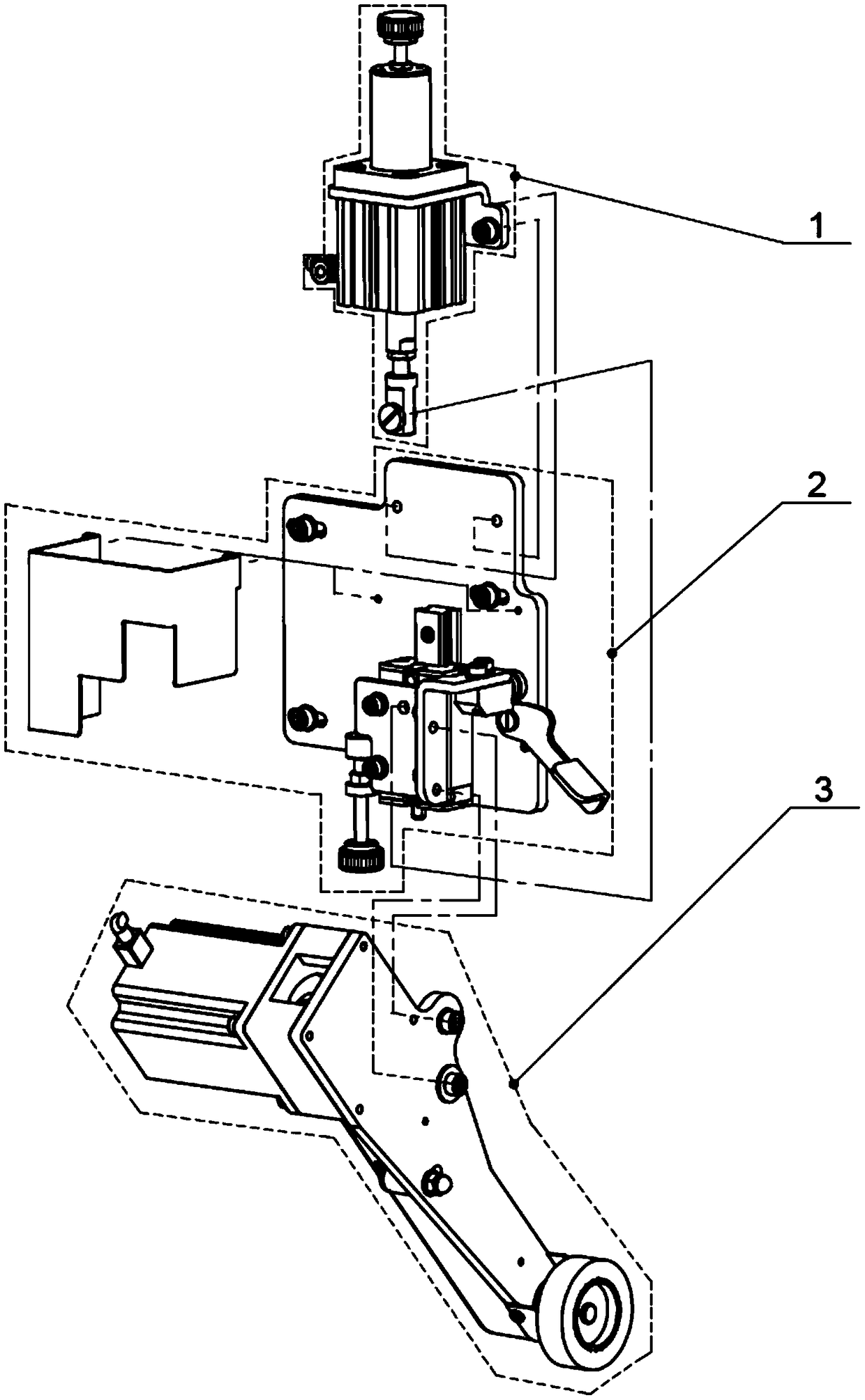

[0036] A sewing machine pneumatic lifting electronic mop mechanism (see Figure 1-Figure 2 ), including an integrated pneumatic lifting and pressing component 1, a vertical guide adjustment component 2 and an electronic mop executing component 3;

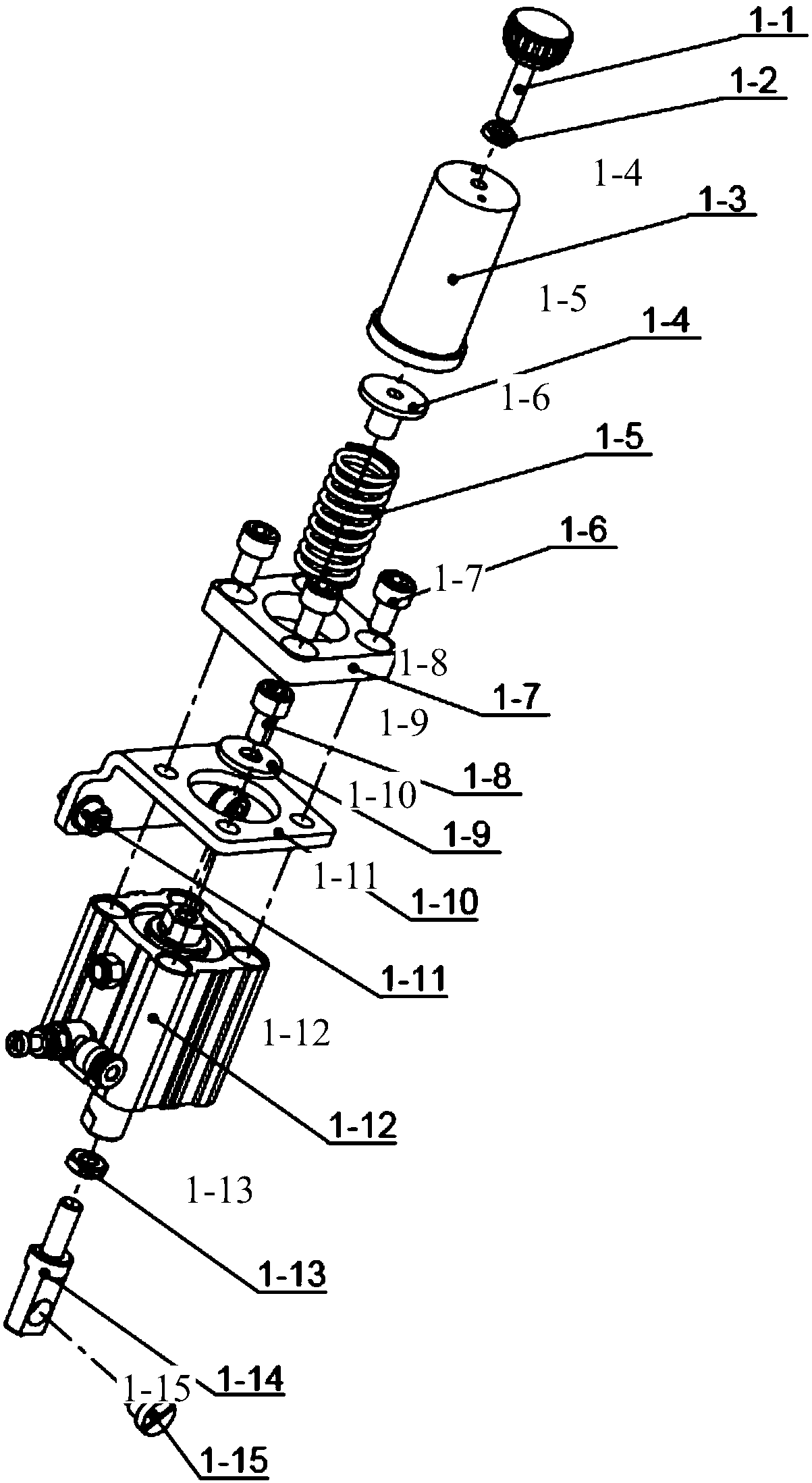

[0037] The one-piece pneumatic lifting and pressing assembly 1 (see image 3 ) including pressure regulating screw 1-1, pressure regulating nut 1-2, spring guide sleeve 1-3, spring pressing block 1-4, spring 1-5, screw one 1-6, fixing block 1-7, screw two 1 -8, large washer 1-9, cylinder bracket 1-10, screw three 1-11, double action cylinder 1-12, nut 1-13, cylinder joint 1-14 and shaft screw 1-15;

[0038]The fixed block 1-7, the cylinder bracket 1-10 and the double-action cylinder 1-12 are arranged in sequence and connected by the screw 1-6, and the pressure regulating nut 1-2 is threaded with the pressure regulating screw 1-1. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com