Device and method for preparing insulating oil immersed insulating paper

A technology of insulating oil and insulating paper, which is applied in the preparation of test samples, paper, papermaking, etc. It can solve the problems of oil-paper insulation performance, easy breakdown, and large test dispersion, so as to eliminate test interference and reduce other problems. Effects of factors to ensure the accuracy of the test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

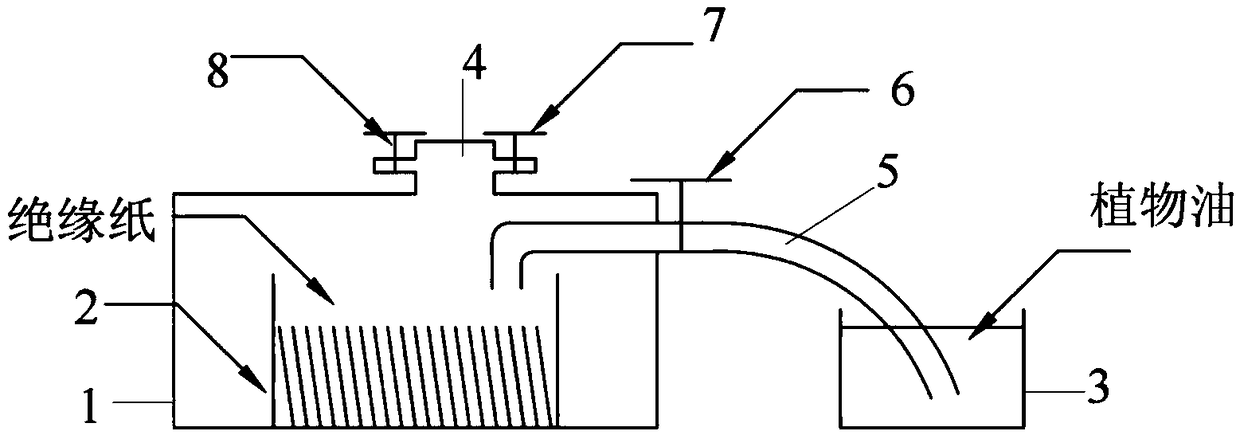

[0050] This embodiment provides a device for preparing insulating oil-impregnated insulating paper, wherein the schematic structural diagram of the device for preparing insulating oil-impregnated insulating paper is as follows figure 1 shown, from figure 1 It can be seen that it includes:

[0051] Suction filtration unit (not shown in the figure), first vacuum drying degassing and dehydration unit (not shown in the figure), second vacuum drying degassing and dehydration unit (not shown in the figure), vacuum sealed tank 1, Oil pool 2, the third vacuum drying degassing and water removal unit (not shown in the figure) and insulating oil storage tank 3;

[0052] The suction filter unit is used to filter the insulating oil to remove impurities therein, and the filter used in the suction filter unit is an organic filter with a pore size of 0.45 μm; in this embodiment, the suction filter unit can be a suction filter bottle;

[0053] The first vacuum drying and degassing and dehyd...

Embodiment 2

[0061] This embodiment provides a method for preparing vegetable oil-impregnated insulating paper, wherein the method is realized by using the device for preparing insulating oil-impregnated insulating paper provided in Example 1, and the method includes the following steps:

[0062] (1) Cut the insulating paper to a suitable size, put it into a vacuum drying oven and dry it at a temperature of 90° C. for 24 hours to degas and remove water;

[0063] Use a suction filter bottle to filter the vegetable oil to remove impurities contained therein, then put the filtered vegetable oil into another vacuum drying oven and dry it under vacuum at 60°C for 24 hours to degas it , except water;

[0064] Put the pretreated insulating paper and the pretreated vegetable oil into the oil pool and the insulating oil storage tank respectively and insert the oil pipe into the insulating oil storage tank;

[0065] (2) Open the vacuum pump and the vacuum valve of the vacuum pump to vacuumize the v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com