Automatic online detecting equipment and method for railroad switch manufacturing process

A technology of manufacturing process and testing equipment, applied in the direction of general control system, program control, digital control, etc., can solve the problems of not having information characteristics, not being able to meet rail parts testing, and not being able to guide process processing, etc., to achieve convenient use and convenience The effect of product information traceability and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] This embodiment provides an automatic online detection device and detection method for the turnout manufacturing process, which can be applied to the CNC machining process of rail parts of different rail types and different gauge baselines. Through online measurement, the geometric dimensions of the CNC milling machining contour can be realized. Automatic detection, improve measurement accuracy, reduce labor intensity of workers, improve production efficiency. Moreover, based on the detection data, the feed rate of the rail parts can be calculated and optimized to guide the optimization and improvement of the forming tool and ensure the processing quality of the product.

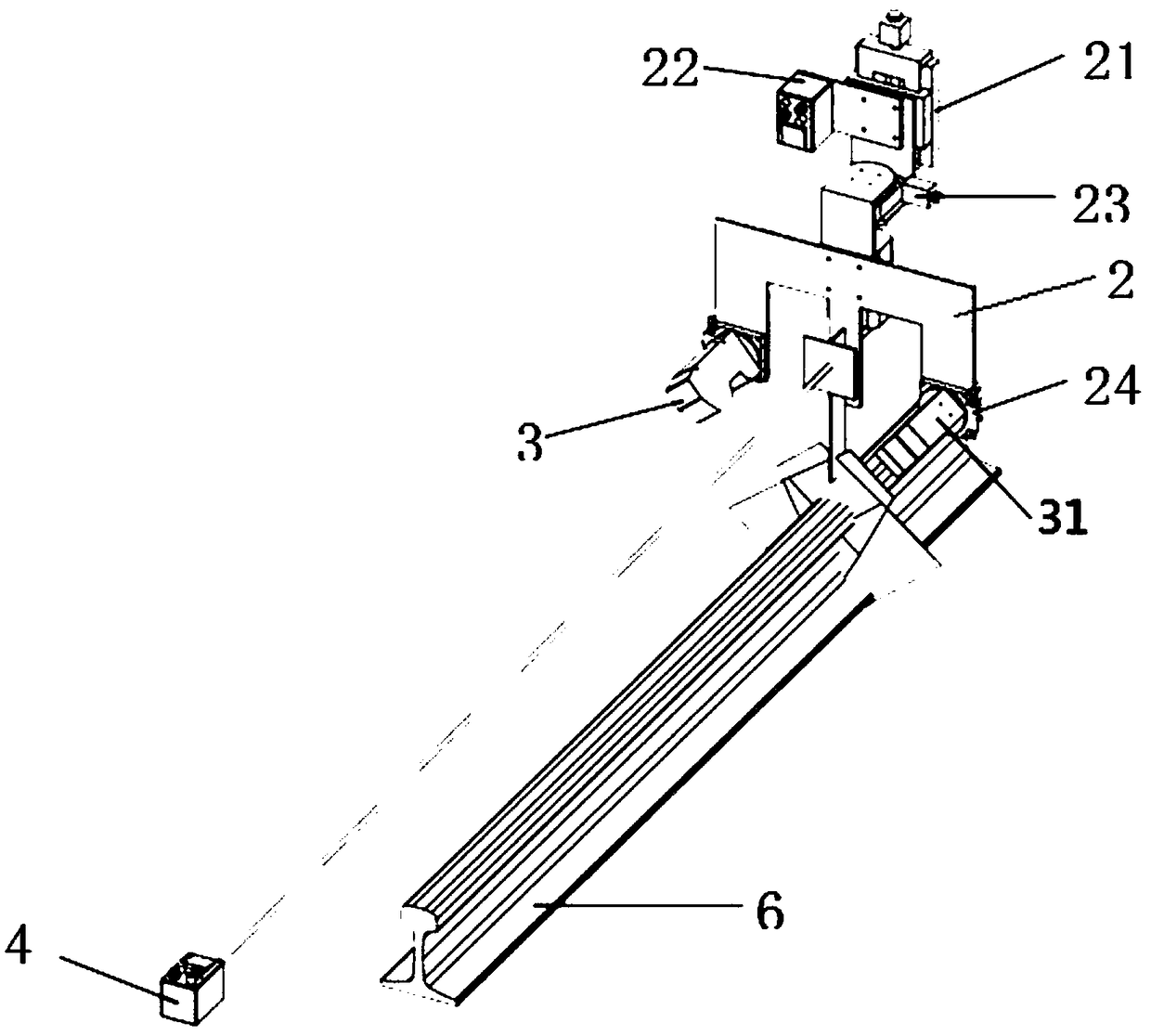

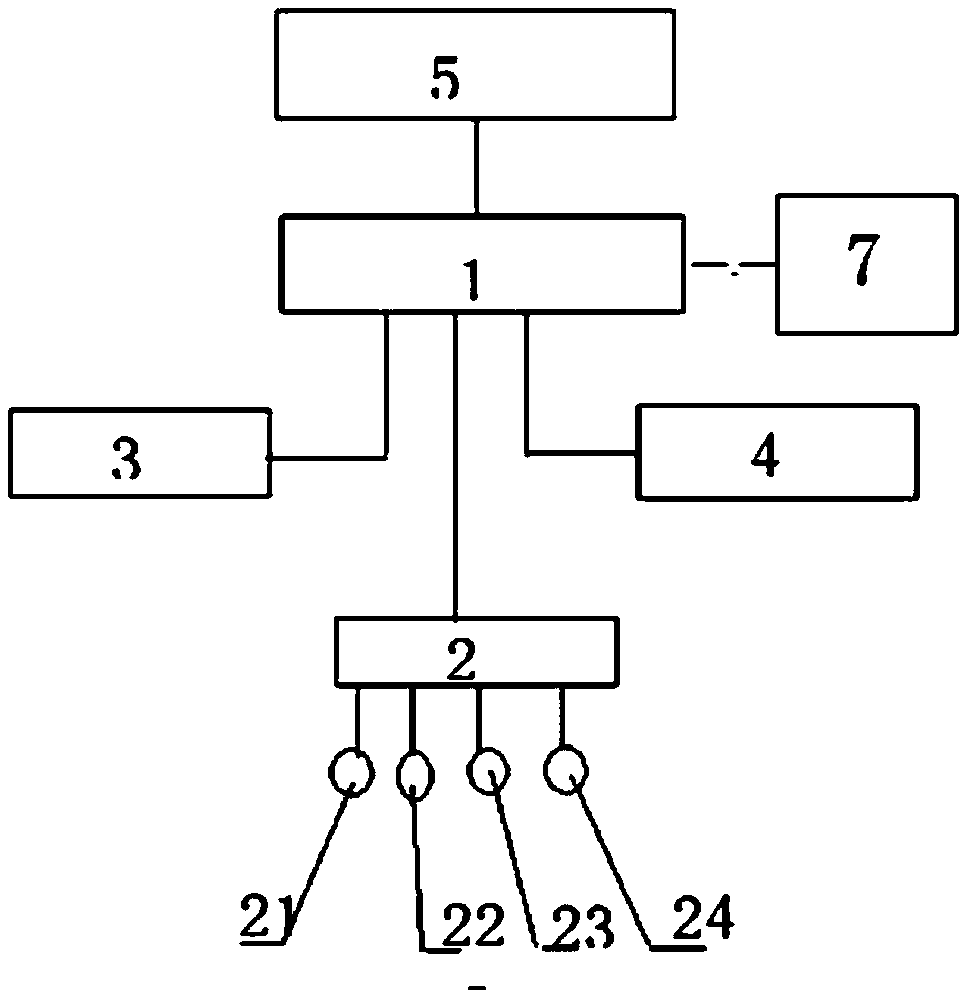

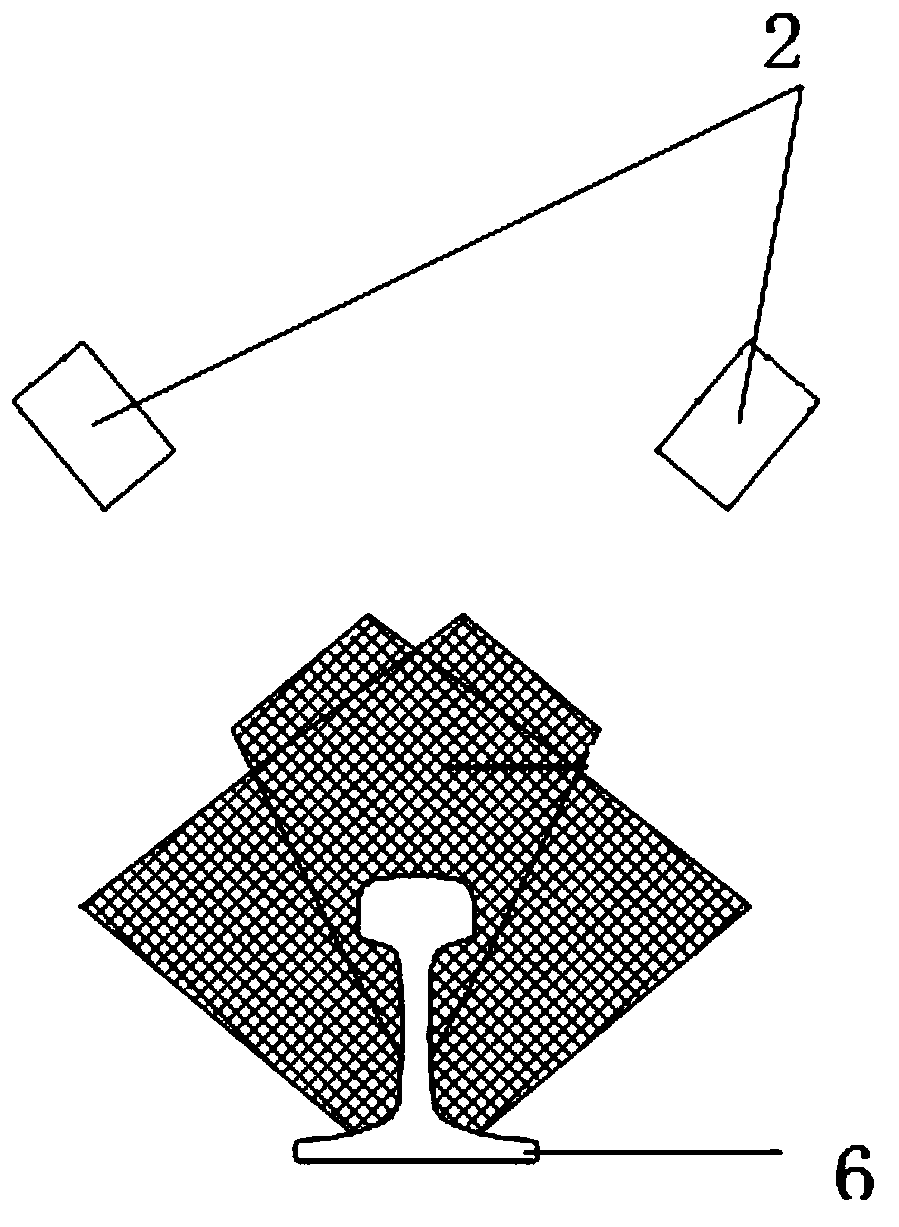

[0042] Such as figure 2 As shown, the on-line detection equipment used in the turnout manufacturing process includes a data receiving and storage module 1, a frame 2, a profile measurement module 3 fixed on the frame 2, a distance measurement module 4 set opposite to the frame 2, and a data processin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com