Cooling unit, heat insulating structure, substrate processing apparatus, and manufacturing method of semiconductor device

A technology for a substrate processing device and a cooling unit, which is used in semiconductor/solid-state device manufacturing, furnace cooling, electrical components, etc., can solve problems such as temperature change differences, and achieve the effect of improving responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] One embodiment of the present invention will be described below with reference to the drawings.

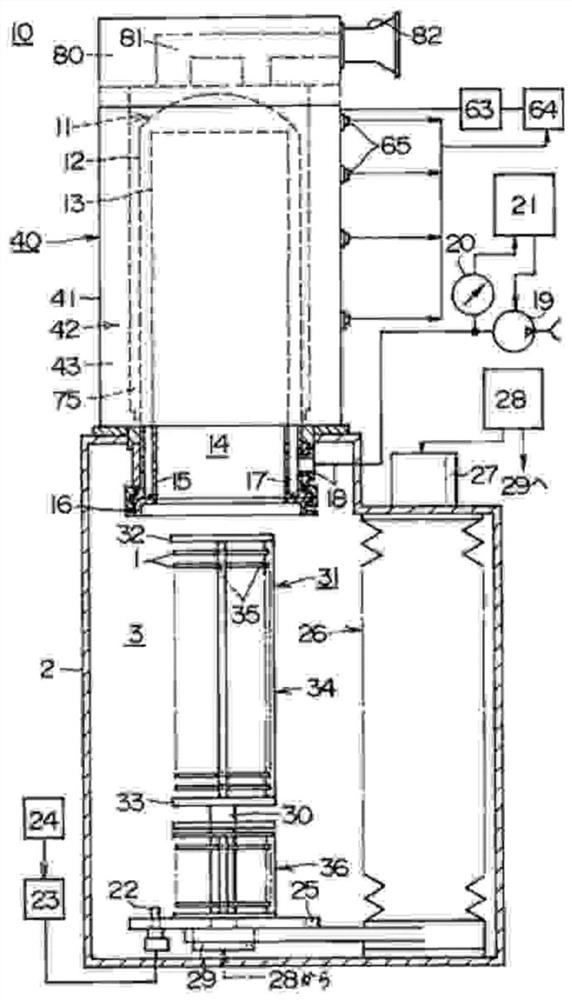

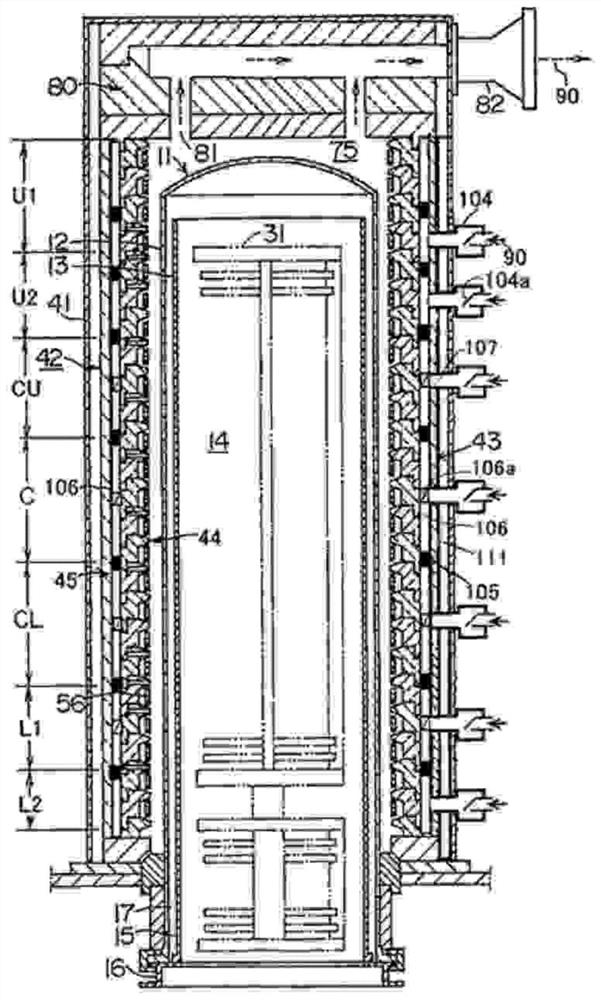

[0029] In this embodiment, if figure 1 and figure 2 As shown, the substrate processing apparatus 10 of the present invention is configured as a processing apparatus 10 for performing a film forming step in a semiconductor device manufacturing method.

[0030] figure 1 The illustrated substrate processing apparatus 10 includes a processing tube 11 as a supported vertical reaction tube, and the processing tube 11 is composed of an outer tube 12 and an inner tube 13 arranged concentrically with each other. Outer tube 12 uses quartz (SiO 2 ) is integrally formed into a cylindrical shape with the upper end closed and the lower end open. The inner tube 13 is formed in a cylindrical shape with upper and lower ends opened. The hollow portion of the inner tube 13 forms a processing chamber 14 into which a wafer boat described later is carried in, and the lower end opening of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com