Preparation method of composite bipolar plate for fuel cell and three-dimensional flow field design scheme

A fuel cell and three-dimensional flow field technology, which is applied to fuel cells, fuel cell components, circuits, etc., can solve problems such as hindering gas mass transfer process, affecting fuel cell power generation process, and fuel cell flooding, so as to reduce water pollution. Probability of "flooding" phenomenon, low gas permeability, and the effect of improving the gas mass transfer process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

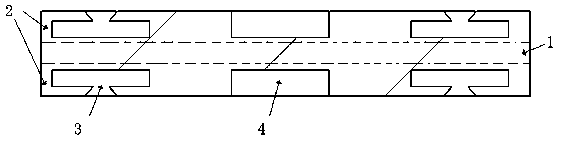

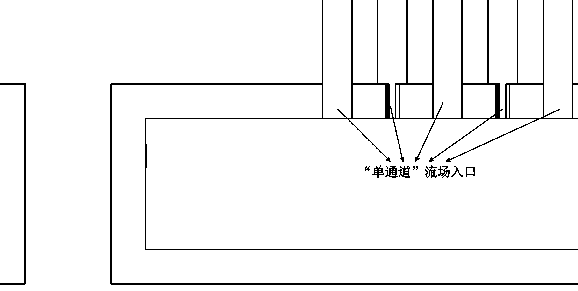

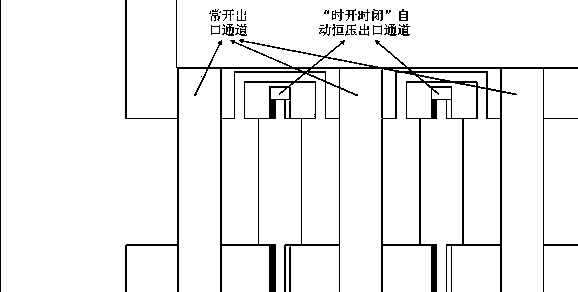

[0032] Such as figure 1 As shown, a composite bipolar plate for fuel cells, the composite bipolar plate has a three-layer structure, the middle layer 1 is composed of a low gas permeability composite carbon plate, which will not be engraved and lost during the engraving process of the subsequent flow field, as The flow field groove part plays the role of separating the cathode and anode reaction gases; the two sides of the middle layer 1 are composed of expanded graphite plates 2 with a porous structure, which form the ridge part of the composite bipolar plate after engraving in the subsequent flow field, so that the reaction gas and The water generated in the power generation process can be transported in its porous structure, which plays the role of increasing the effective area of reaction gas transmission and improving the drainage efficiency of fuel cells. The three-dimensional flow field engraved on the expanded graphite plate 2 is a flow field in which the flow channe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com