Medical disposable protection sleeve and production method thereof

A manufacturing method and a technology of a protective cover, applied in the field of medical devices, can solve problems such as cross-infection, achieve low cost, facilitate large-scale promotion and use, and facilitate loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

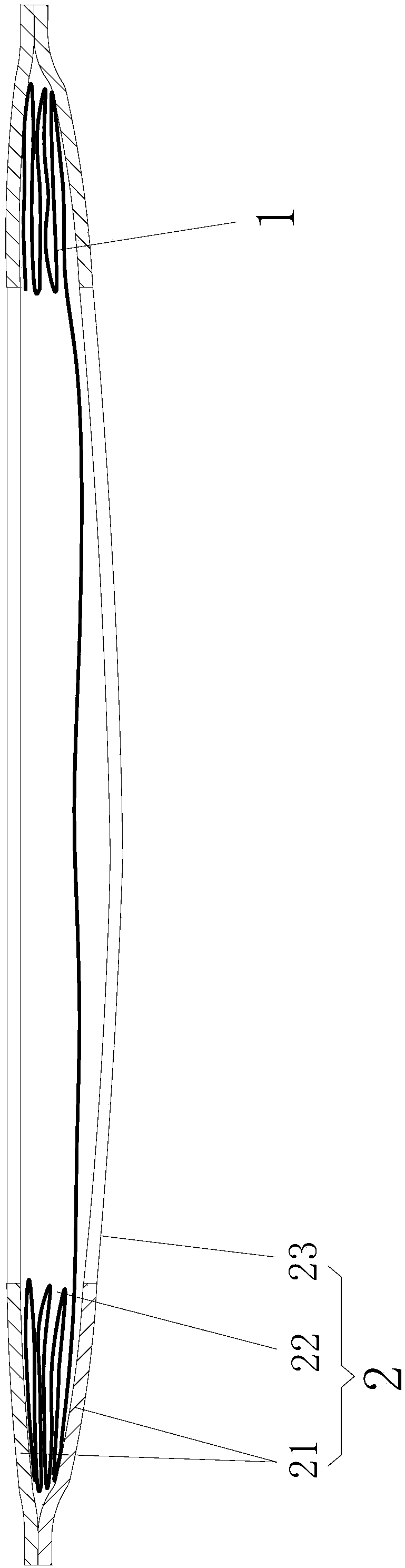

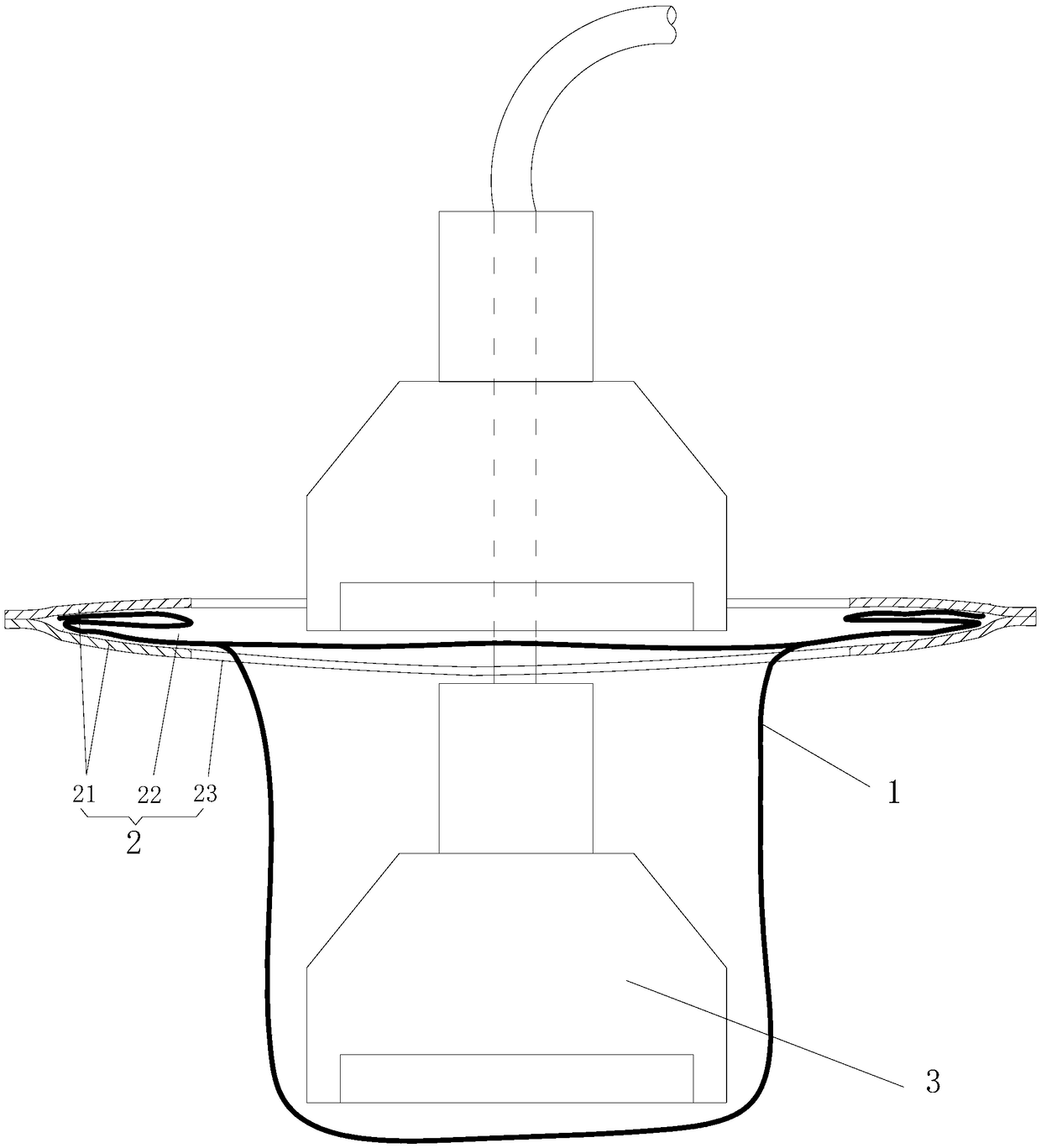

[0040] Such as Figure 1-Figure 3 Shown is a schematic structural diagram of Embodiment 1 of a medical disposable protective cover of the present invention, which is characterized in that it includes a bag 1 with an opening at one end and a housing assembly 2 for storing the bag 1;

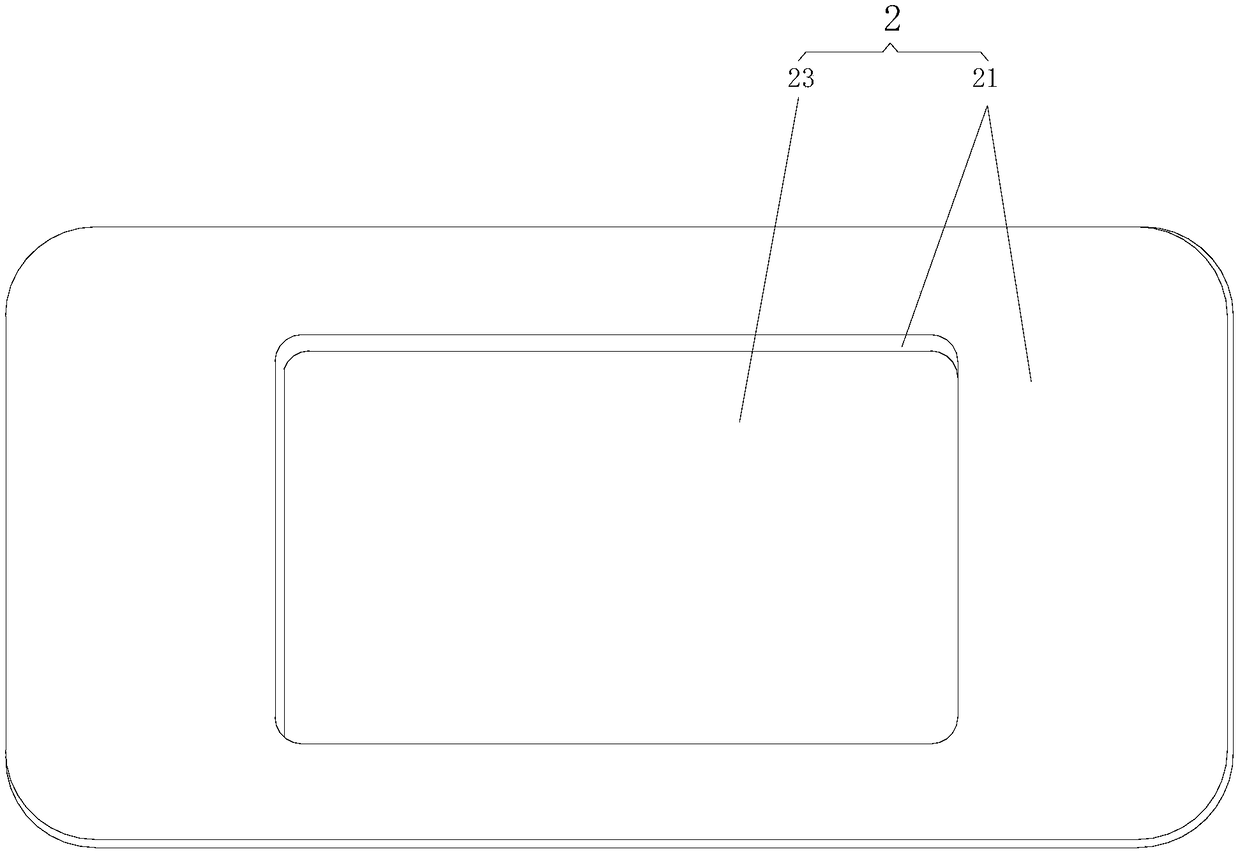

[0041] The housing assembly 2 is composed of two superimposed substrates 21, the edges of the two substrates 21 are fixedly connected together, and a storage cavity for accommodating the bag 1 is provided between the inner side walls of the two substrates 21. 22, and each substrate 21 is respectively provided with a window 23 corresponding in position and shape, and each window 23 communicates to form a channel for penetrating the instrument probe 3;

[0042] The bag 1 is folded and compressed along the direction vertical to the bag mouth from the mouth of the bag to the end of the bag, and then placed in the storage cavity 22. The position of the mouth of the folded bag 1 corresponds to the openi...

specific Embodiment approach 2

[0051] A manufacturing method for preparing the medical disposable protective cover described in Embodiment 1, characterized in that: the method comprises the following steps:

[0052] Step 1: Put the core 5-missing figure and label into the bagging 1, pull the bagging 1 flat, and make the pocket of the bagging 1 be at the top;

[0053] Step 2: Place a base plate 21 horizontally on the workbench, and then place the lower end of the core 5 covered with the bagging 1 at the position of the window 23 on the base plate 21 and put it down vertically;

[0054]Step 3: Place the window 23 of another base plate 21 on the outer periphery of the upper end of the core 5, so that the pocket edge of the bagging 1 is located below the edge of the window 23 of the other base plate 21, so that the base plate 21 moves downward and drives The pocket opening of the bagging 1 is pressed and folded along the extension direction of the core 5 until the bagging 1 is folded and pressed into the storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com