Low-consumption high-efficiency sand shaking machine

A sand-shaking machine and sand-shaking technology are used in solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., and can solve the problems of incomplete shaking, loss of sand and gravel, and sand breaking, etc. Achieve the effect of improving the production qualification rate and improving the fineness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

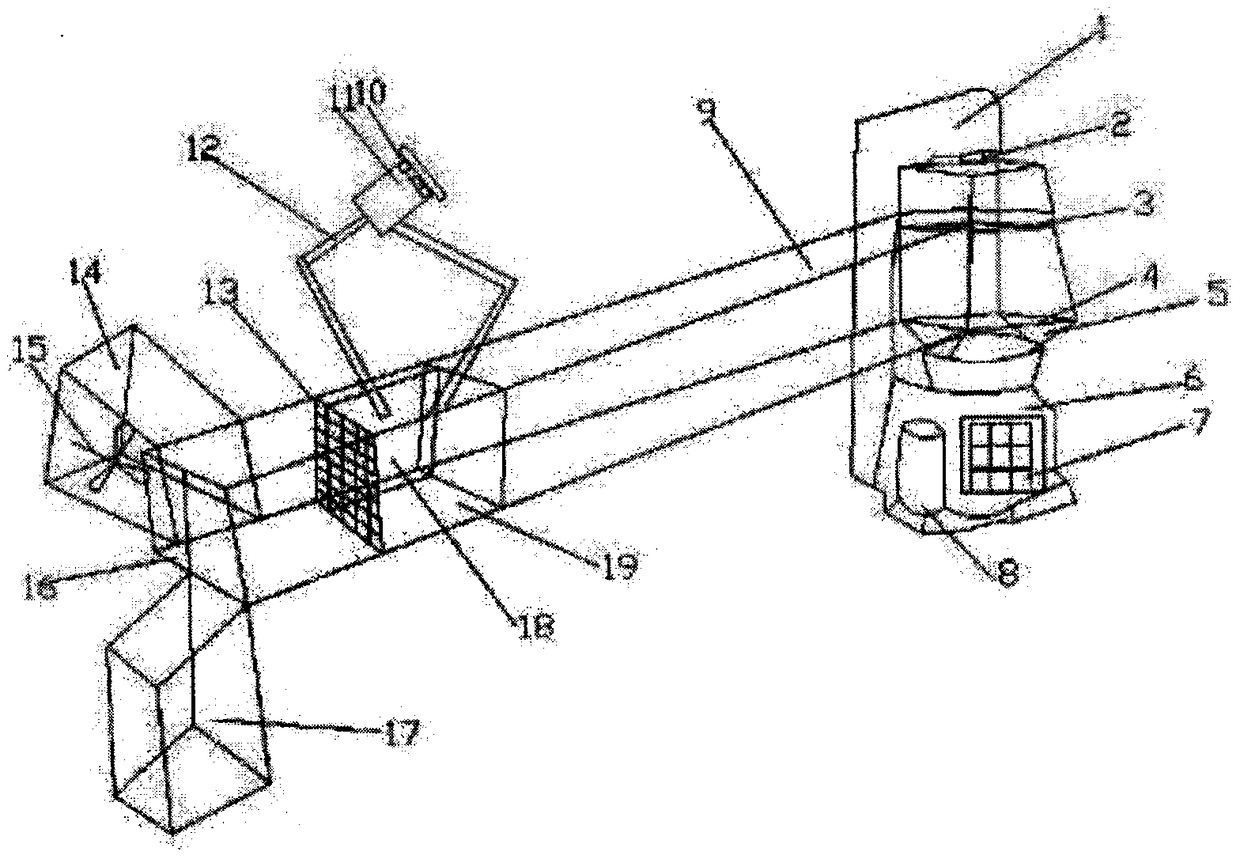

[0024] Such as figure 1 A low-consumption and high-efficiency sand shaker is shown, comprising a sand shaker body 1 and a sand shaker working shell 5. The sand shaker body 1 is fixed with a connecting rod 2, and the connecting rod 2 is welded to the sand shaker working shell. 5, the sand shaking upper plate 3 and the shaking sand bottom plate 4 are fixed and fixed in the sand shaking working shell 5, the sand shaking working shell 5 is fixed above the base 6, and the base 6 is fixed with a controller 7, so The side of the base 6 is provided with an engine 8, the sand-shaking working shell 5 is fixedly connected to a filter channel 9, a filter screen 13 is fixed in the filter channel 9, and the filter channel 9 is slidably connected with a sand pushing wall 18, the filter channel 9 is internally fixed with a sand pushing door 19, the filter channel 9 is welded with an air box 14, and the end of the filter channel 9 is threadedly connected with the sand storage device 17.

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com