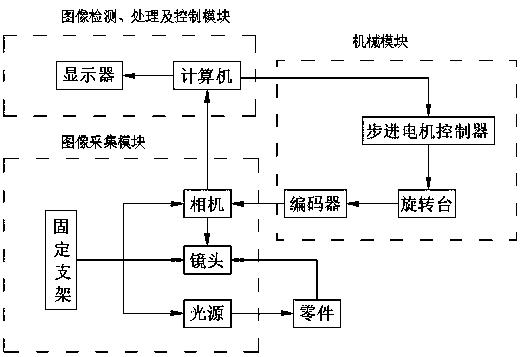

Mechanical part vision detection system

A technology for mechanical parts and visual inspection, applied in the field of visual inspection systems, can solve problems such as improvement, environmental hazards, energy waste, product cost, etc., and achieve the effect of improving inspection efficiency and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

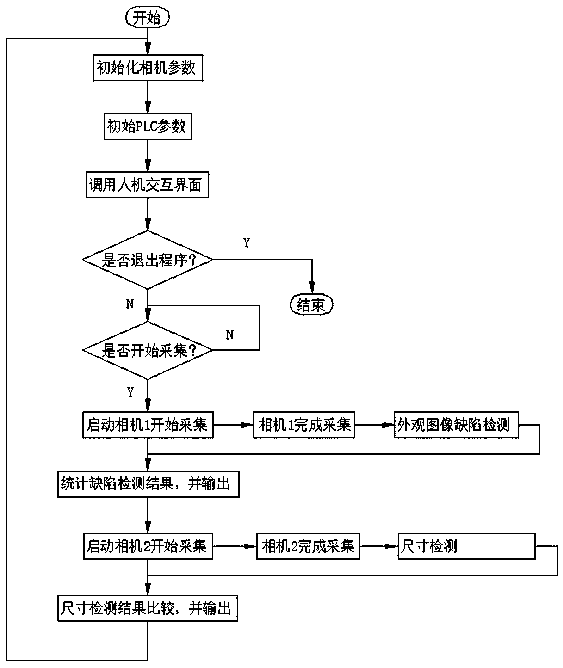

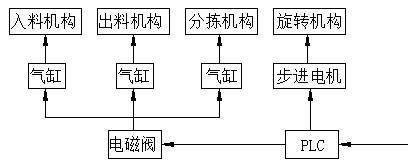

Method used

Image

Examples

Embodiment 2

[0035] In order to improve the measurement speed of mechanical parts, the present invention adopts the method of multi-position parallel operation in the design of the measuring device, and designs an indexing plate structure with multiple measuring stations, which are respectively used for feeding, testing and measuring of mechanical parts. Sorting, so that the main process of measurement can be completed at the same time. In order to ensure the accuracy of measurement, the indexing plate with high positioning accuracy should be selected. The indexing plate is equipped with multiple stations, which are evenly distributed on the indexing plate. For the operations of feeding, measuring and sorting mechanical parts, the specific work of the measuring device is as follows: the sub-reading plate rotates one station at a time according to a fixed cycle; station 1 is used for the loading and positioning operation of mechanical parts; Station 2 detects whether there are parts through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com