Conveyer for battery exchange

A transporter and battery technology, which is applied in the direction of transportation and packaging, charging stations, electric vehicles, etc., can solve the problems of large lifting cranes, inability to be widely distributed, and high site requirements, and achieve simple and reliable structure and use, heavy load, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

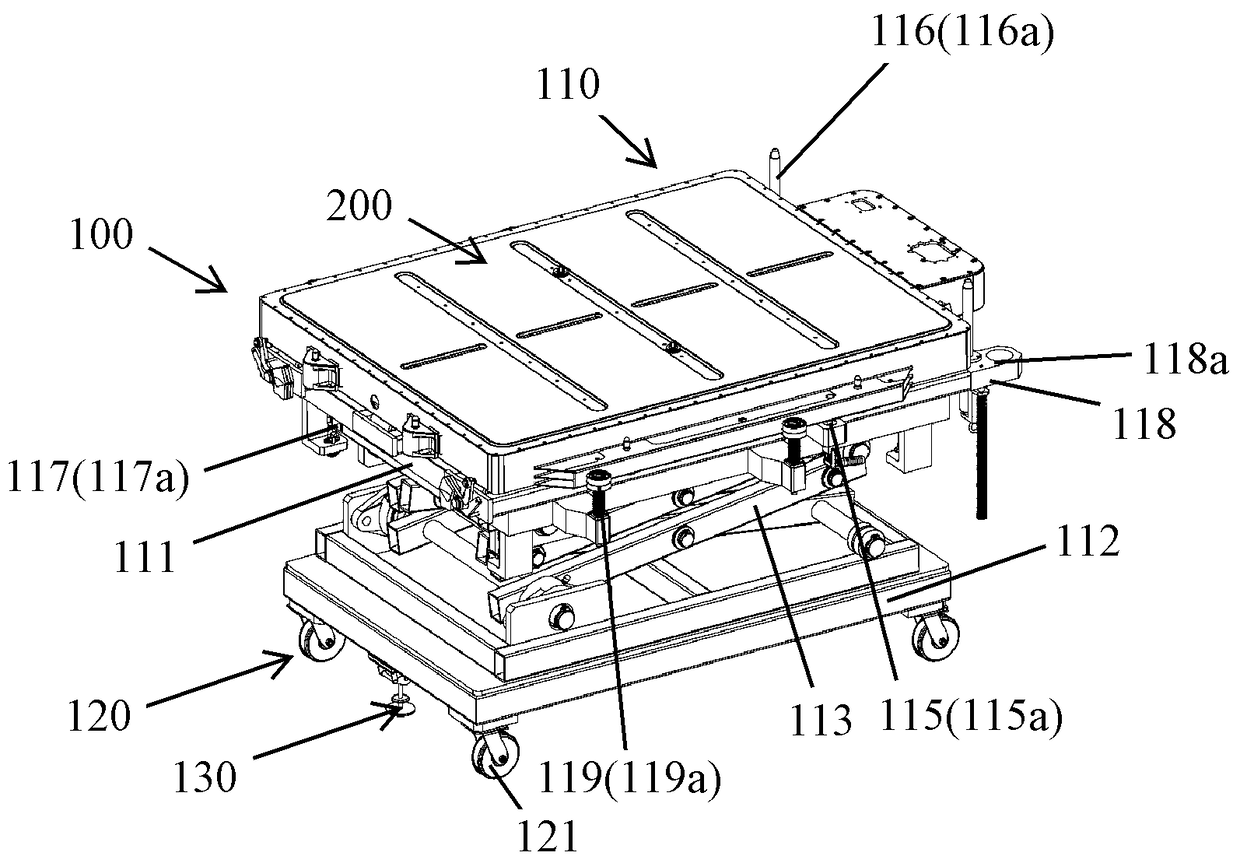

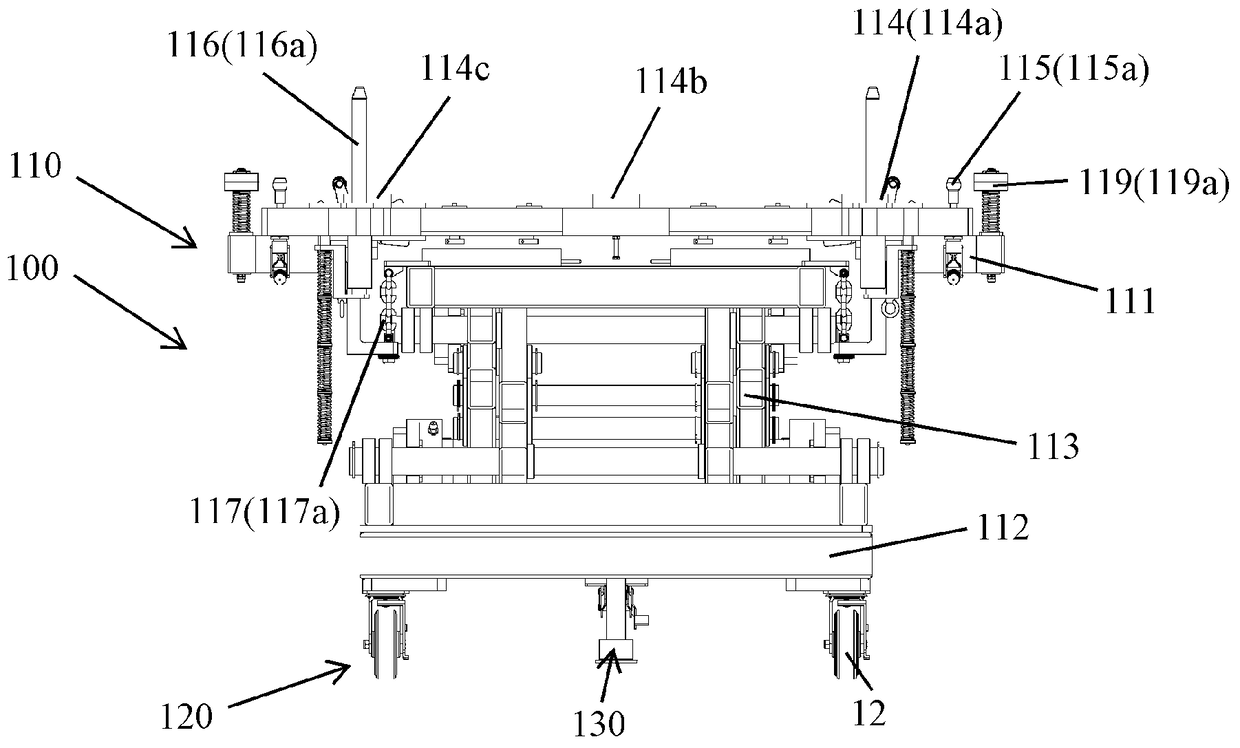

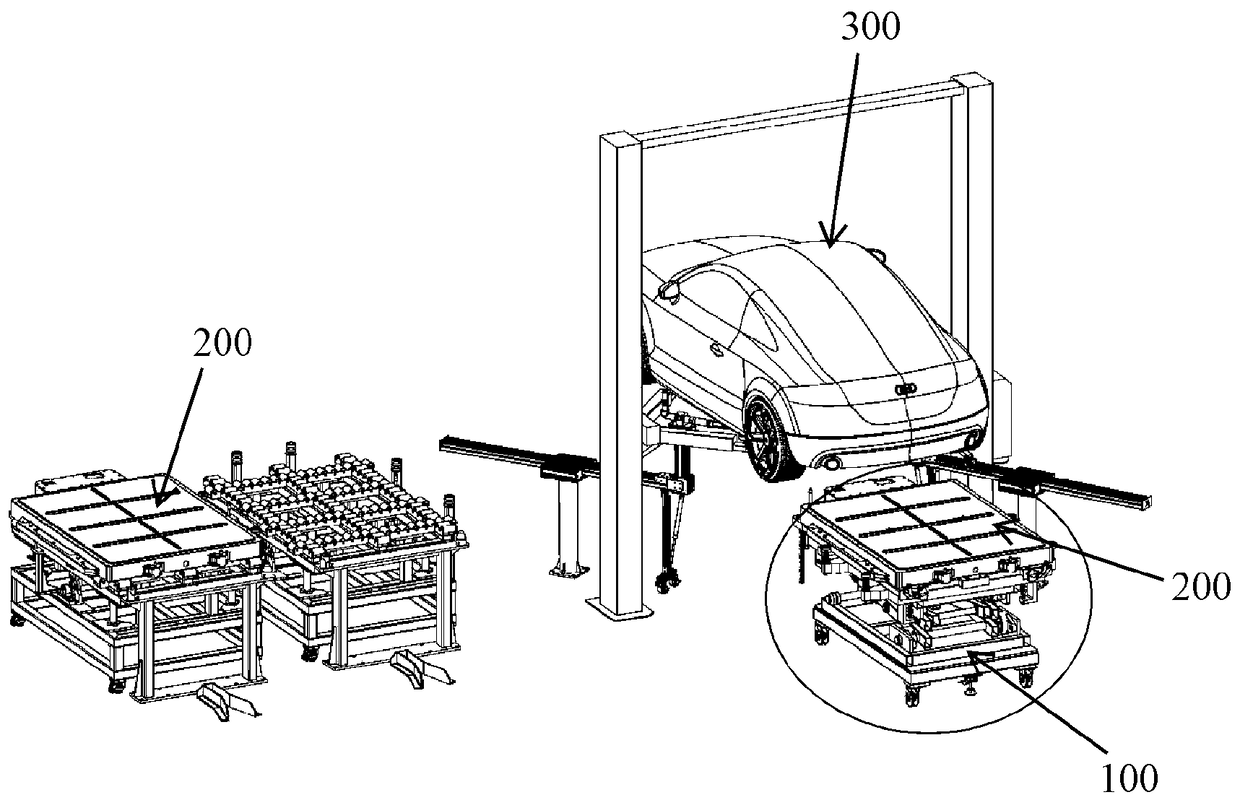

[0023] According to the idea of the present invention, an embodiment of a battery-swapping transporter is provided here with reference to the accompanying drawings. see Figure 1 to Figure 2 , the battery swap transporter 100 includes a carrying portion 110 and a moving portion 120 , wherein the carrying portion 110 is used for carrying and lifting functions during battery loading and unloading, and the moving portion 120 is used for realizing walking of the battery swapping transporter 100 .

[0024] Specifically, the carrying part 110 includes: a carrying plate 111 for carrying the battery to be transported, and a battery delivery mechanism 114 is arranged on the carrying plate 111; a bottom plate 112 providing an installation position for the moving part 120; 112 between the lifting mechanism 113, and the lifting mechanism 113 can be controlled to lift to change the vertical distance between the carrying plate 111 and the bottom plate 112. The moving part 120 is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com