A kind of glass cleaner for automobile and preparation method thereof

A cleaning agent and glass technology, which is applied in the preparation of detergent mixture compositions, chemical instruments and methods, detergent compounding agents, etc. The effect of low surface tension, rapid and complete biodegradation, and strong wetting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a glass cleaner for automobiles, the parts by weight of the raw materials of the cleaner are as shown in Table 1 #1.

[0045] The preparation method of described automobile glass cleaner is:

[0046] A) Pre-dissolve the anionic surfactant in water into a certain proportion of the solution according to the weight fraction ratio described in Table 1-1#, and the amount of the water is 5-15% of the total water;

[0047] B) Add water accounting for 40-60% of the total water in the chemical tank, add the anionic surfactant solution pre-dissolved in step (A), non-ionic surfactant and additives in turn while stirring, and stir to dissolve completely;

[0048] C) Then add solvent, preservative and corrosion inhibitor in sequence, stir well and then add pH adjuster to adjust pH to 6.5-10;

[0049] D) Finally, add the pigment, make up the remaining water, stir, and filter to obtain the antifreeze type automobile glass cleaner.

[0050] The freezing point...

Embodiment 2

[0059] This embodiment provides another glass cleaner for automobiles, the parts by weight of the raw materials of the cleaner are as shown in Table 1 #2. Refer to Example 1 for the preparation method of the glass cleaner.

[0060] The freezing point of the automotive glass cleaner is -42°C, and the flash point is 65°C.

[0061]Detect the detergency and corrosivity of described automobile glass cleaner respectively:

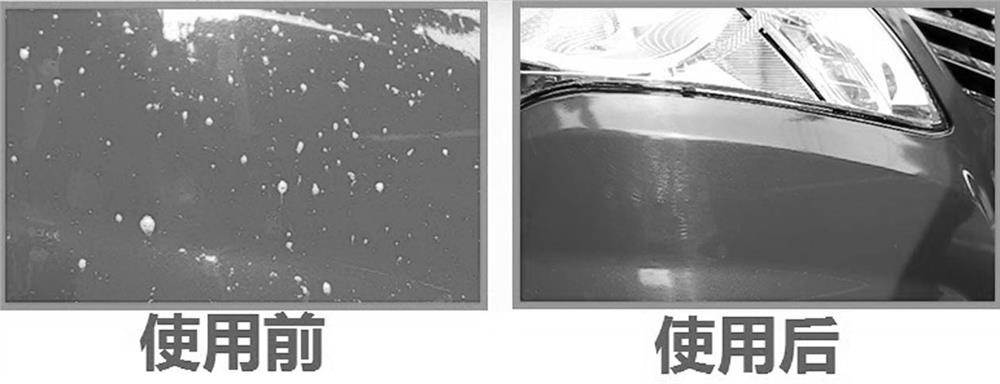

[0062] (1) Detergency: The glass cleaner was tested according to the standard GB / T 23436. After the test, if figure 2 As shown, it has a good decontamination effect on the stains on the car glass without residue.

[0063] (2) Corrosion: According to the GB / T 23436 standard, the corrosion test was carried out on aluminum sheets, copper sheets, and galvanized steel sheets using the glass cleaner. According to the test results, the glass cleaner is non-corrosive to the three materials.

Embodiment 3

[0065] This embodiment provides another glass cleaner for automobiles, the parts by weight of the raw materials of the cleaner are as shown in Table 1 #3. Refer to Example 1 for the preparation method of the glass cleaner.

[0066] The freezing point of the automotive glass cleaner is -43°C, and the flash point is 66°C.

[0067] Detect the detergency and corrosivity of described automobile glass cleaner respectively:

[0068] (1) Detergency: The glass cleaner was tested according to the standard GB / T 23436. After the test, if image 3 As shown, it has a good decontamination effect on the stains on the car glass without residue.

[0069] (2) Corrosion: According to the GB / T 23436 standard, the corrosion test was carried out on aluminum sheets, copper sheets, and galvanized steel sheets using the glass cleaner. According to the test results, the glass cleaner is non-corrosive to the three materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com