Drain valve plug and washing machine

A technology for drain valves and washing machines, which can be applied to other washing machines, washing devices, textiles and papermaking, etc., and can solve problems affecting detection accuracy, complex detection structures, cumbersome assembly processes, etc. The effect of low rate and avoiding cross-infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

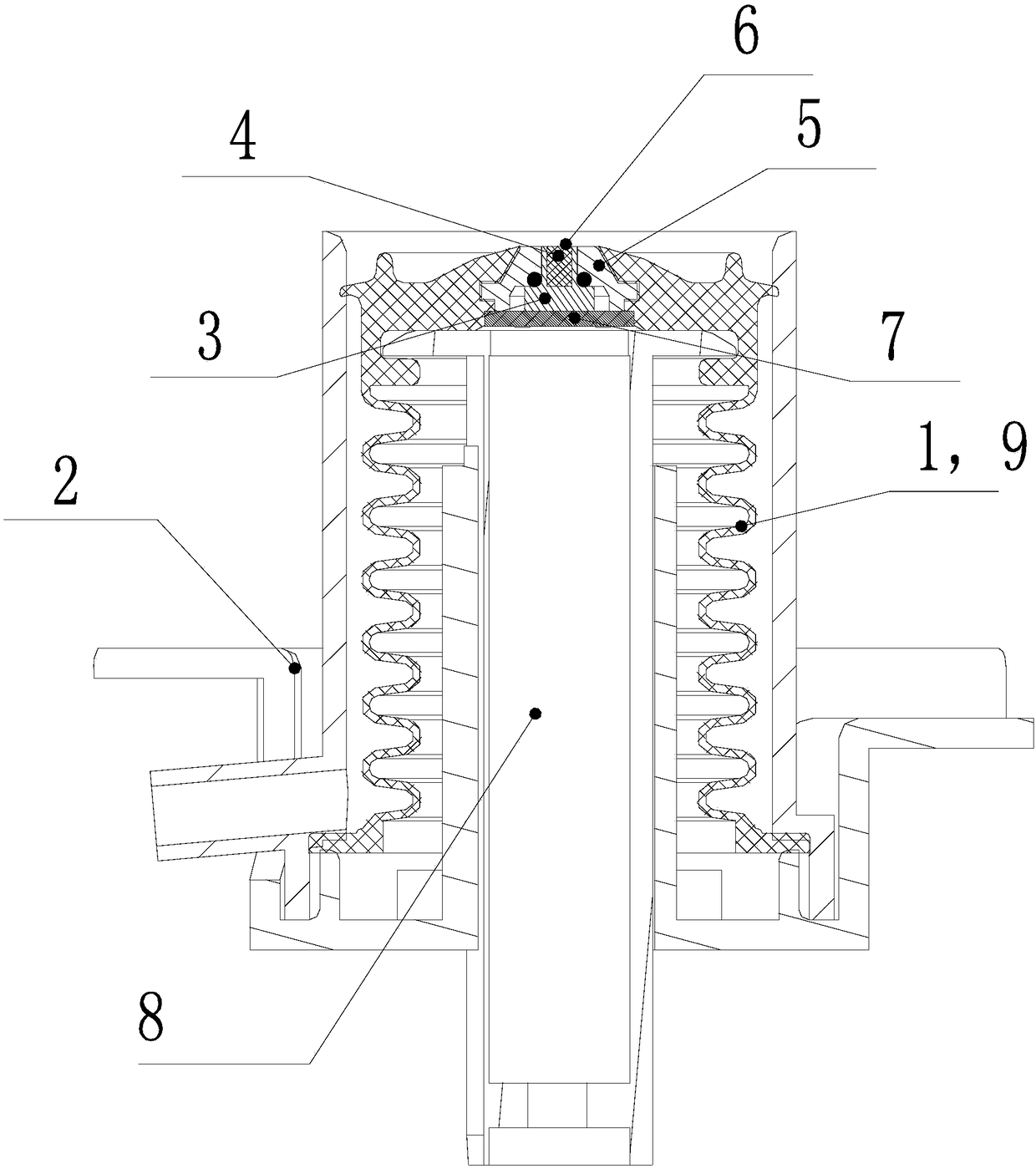

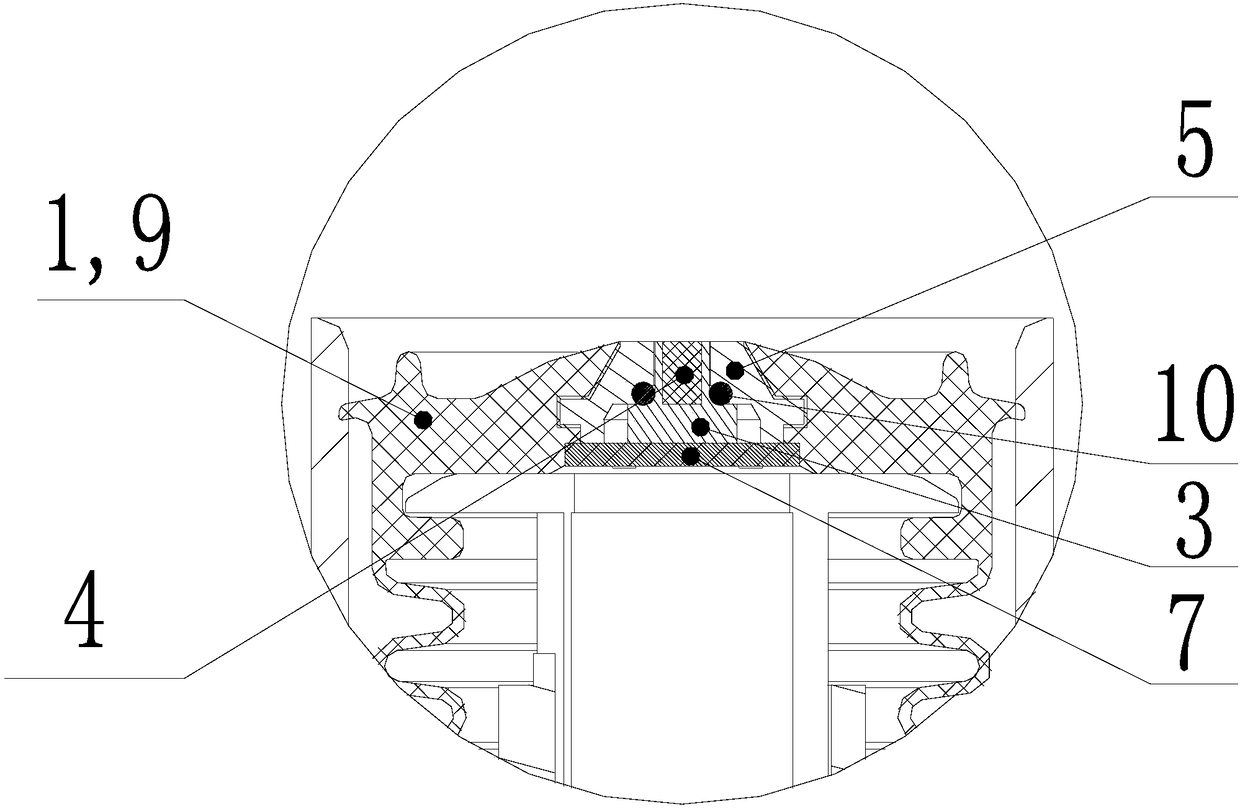

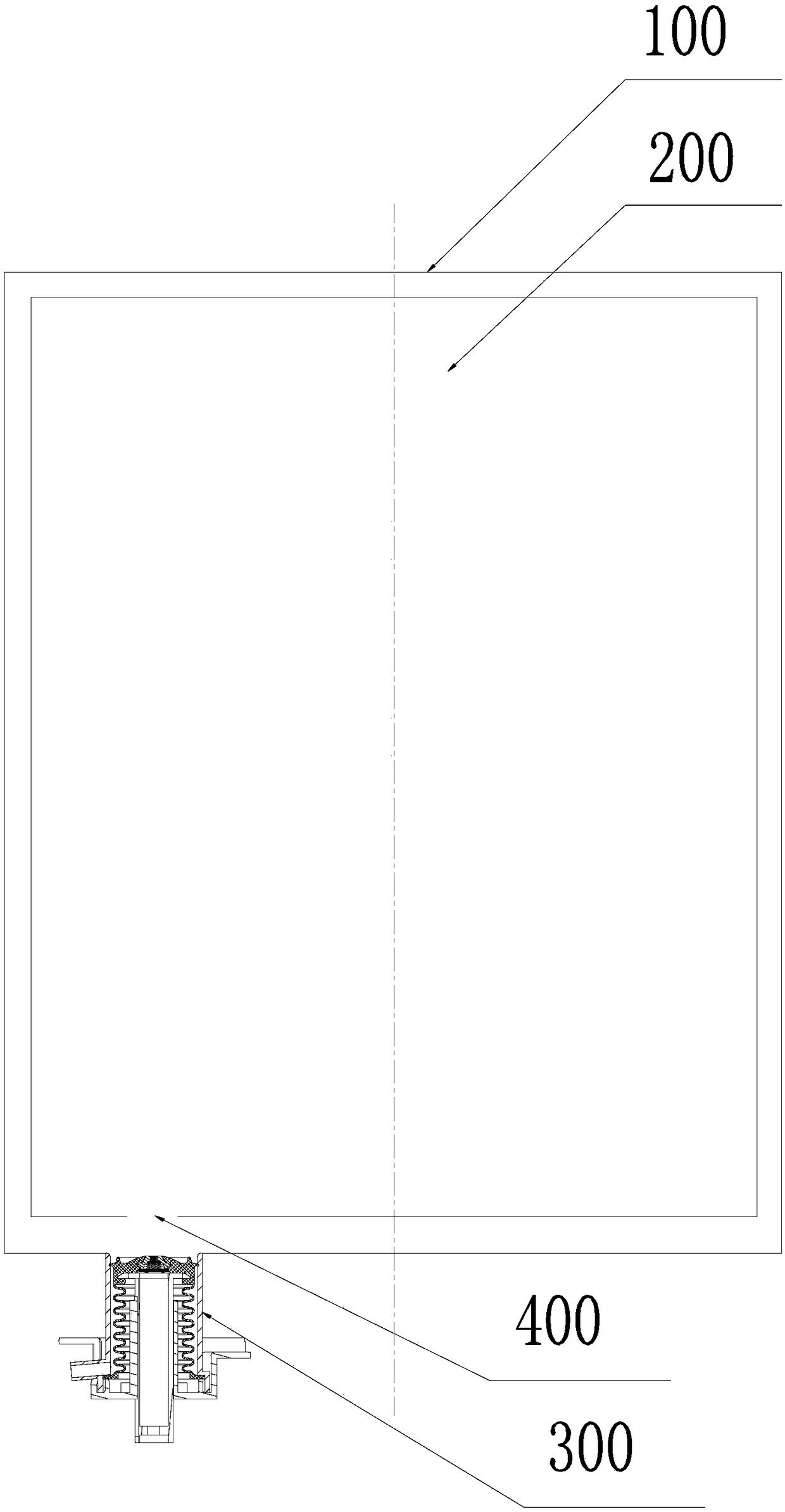

[0031] like Figure 1 to Figure 3 As shown, this embodiment introduces a drain valve plug 300, which includes a valve plug housing 2, a rubber valve plug core 1 that can move axially and telescopically is installed in the valve plug housing 2, and the telescopic end of the rubber valve plug core 1 A pressure sensor 3 is installed, and the pressure sensor 3 detects the water pressure at the telescopic end of the rubber valve plug core 1 .

[0032] By installing a pressure sensor at the end of the rubber valve plug core of the drain valve plug, the water pressure at the drain port blocked by the drain valve is detected, and then the liquid water level in the corresponding installation container of the drain valve is obtained to realize integrated controllable opening and closing of drainage Dual function of valve and level detection.

[0033] In this embodiment, the pressure sensor 3 communicates with the external water flow through the pressure guiding block 4 made of high ela...

Embodiment 2

[0044] The difference between this embodiment and the first embodiment above is that the pressure sensor is directly sealed inside the rubber valve plug core. The rubber valve plug includes a push-pull rod and a set of sealing sleeves on the telescopic end of the push-pull rod. The pressure sensor is clamped between the telescopic end of the push-pull rod and the sealing sleeve. The sealing sleeve is made of elastic materials such as rubber, so that the external water pressure is elastically The sealing sleeve is transmitted to the pressure sensor, so that the pressure sensor can indirectly detect the external water pressure through the sealing sleeve, and then realize the purpose of detecting the external water pressure of the drain valve plug; at the same time, the pressure sensor can also be sealed in the sealing sleeve , to prevent the pressure sensor from contacting with water.

Embodiment 3

[0046] The difference between this embodiment and the above-mentioned first embodiment is that the top cover is made of elastic material, and there is no pressure guide port on it, and the pressure sensor is clamped between the top cover and the push-pull rod to obtain the external water pressure through the elastic top cover. It is transmitted to the pressure sensor, so that the pressure sensor can indirectly detect the external water pressure through the top cover, and then realize the purpose of detecting the external water pressure of the drain valve plug; at the same time, the pressure sensor can also be sealed in the top cover to prevent pressure Occurrence of sensor contact with water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com