Walking type trackless triangular hanging basket and construction method thereof

A triangular hanging basket and walking-type technology, which is applied in the direction of erecting/assembling bridges, bridge materials, bridges, etc., can solve the problems that the subsidence deflection affects the line shape of the beam body, etc., so as to reduce the construction risk of hanging baskets, reduce settlement and save energy. The effect of construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

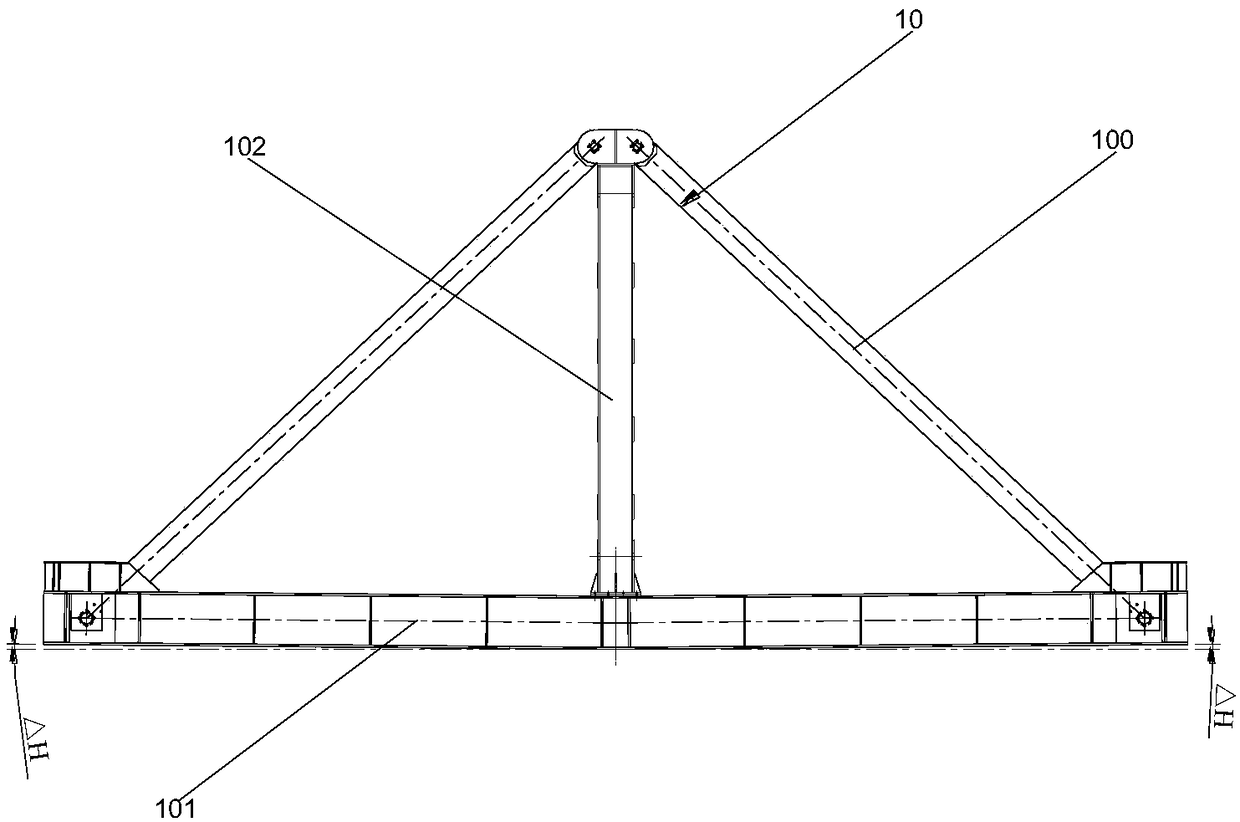

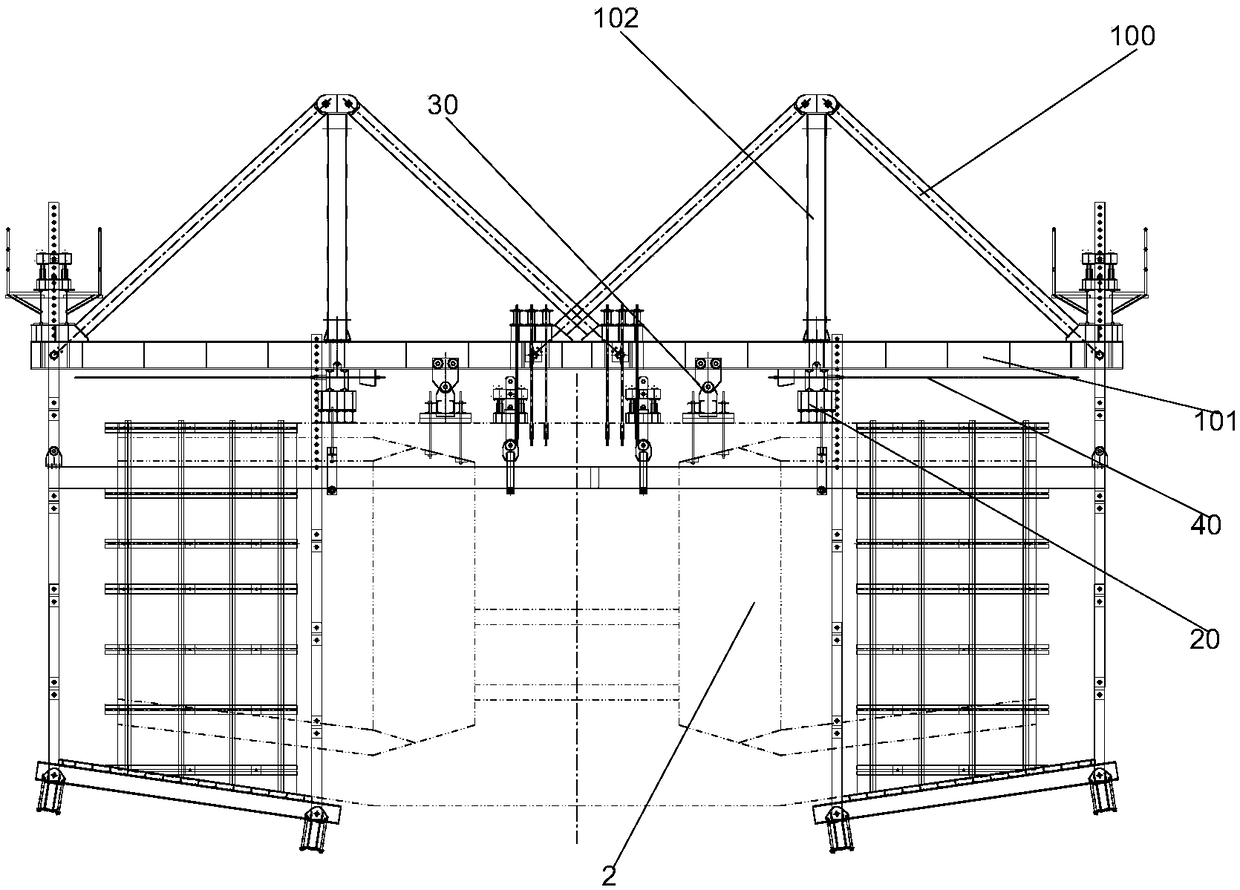

[0049] see figure 1 As shown, Embodiment 1 of the present invention provides a triangular main truss of a walking-type trackless triangular hanging basket, and the triangular main truss 10 includes:

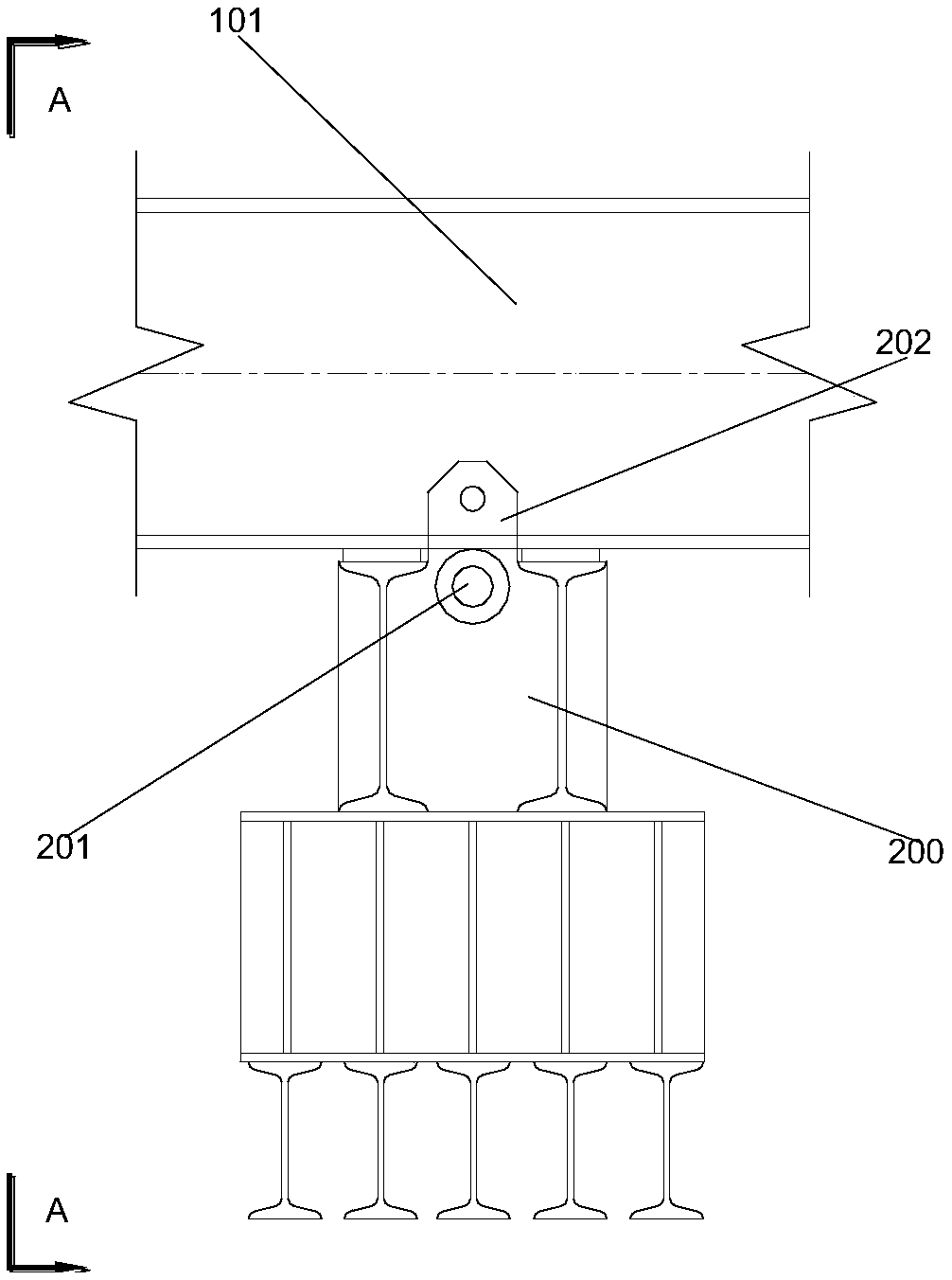

[0050] horizontally arranged main stringers 101;

[0051] The bottom end is connected to the column 102 of the main longitudinal beam 101;

[0052] Two diagonal stay rods 100, the bottom ends of the two diagonal stay rods 100 are respectively connected to the two ends of the main longitudinal beam 101, and the top ends are connected to the top of the column 102; The intersection point is the center, and the level is inclined upward at a certain angle.

[0053] Establish a MIDAS model for the hanging basket of the embodiment of the present invention, load and simulate the construction state to determine the sinking deflection value of the trian...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com