Electric hanging basket weighting mechanism and construction method

A construction method and a hanging basket technology are applied to the electric hanging basket counterweight mechanism and the construction field to achieve the effects of cost saving, low transportation cost and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings.

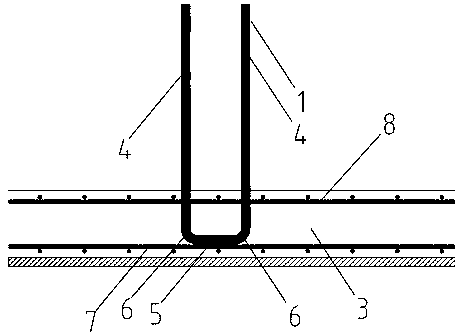

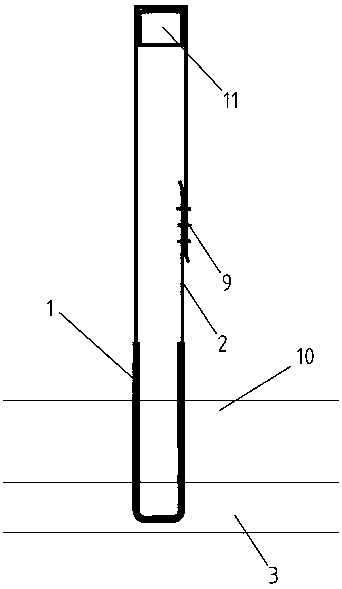

[0034] For specific implementation: see Figure 1 to Figure 2 , an electric hanging basket counterweight mechanism, including a hollow casing 1 and a steel wire rope 2, the casing 1 is partly embedded in the roof concrete layer 3, and its two ends respectively protrude from the concrete layer 3 to the outside of the surface layer 10, so that The steel wire rope 2 passes through the casing 1 and is fixed on the cantilever beam 11 of the electric hanging basket to form the counterweight of the electric hanging basket. Generally, the two ends of the casing protrude 50mm outside the surface layer, which is convenient for threading the wire rope later.

[0035] As an optimization, the casing 1 is a U-shaped casing, the bottom end of which is pre-embedded in the roof concrete layer 3 . In practice, it is not limited to U-shape, but may also be V-shape, W-shape, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com