A water removal device before organic waste treatment

A technology before the treatment of organic waste, applied in the direction of heating device, dryer, drying gas arrangement, etc., can solve the problems of complex dewatering operation and low efficiency, and achieve good dewatering effect, high work efficiency and convenient use Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

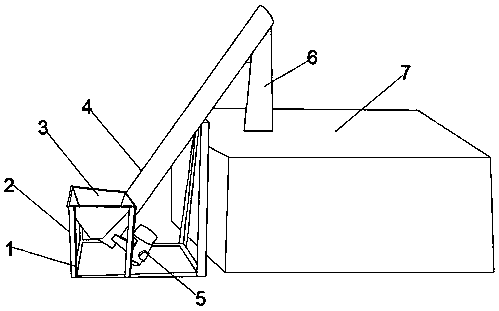

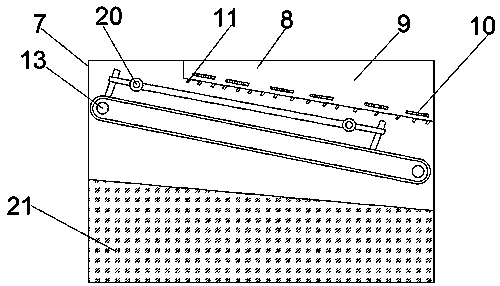

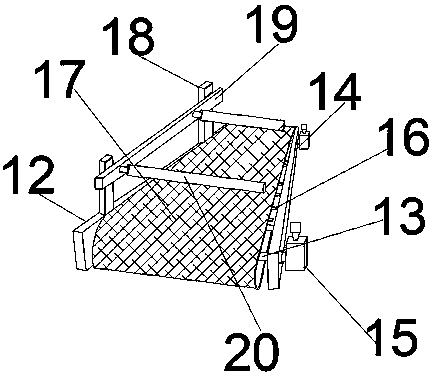

[0018] Such as Figure 1-3 As shown, a water removal device before the treatment of organic waste includes a conveying assembly 1, and the conveying assembly 1 includes a fixed support 2, a feed hopper 3, an auger 4, a first motor 5 and a pipeline 6, and the A feed hopper 3 is installed on one side of the top of the fixed bracket 2, an auger 4 is installed on the outer side of the feed hopper 3 through the fixed bracket 2, and a first motor 5 is installed on the lower side of the auger 4, A pipeline 6 is installed on the upper side of the auger 4, a casing 7 is installed at the bottom of the pipeline 6, and a water removal assembly 8 is installed on the top side of the inner top of the casing 7, and the water removal assembly 8 includes Fixed table 9, fan 10 and deflector 11, fan 10 is installed at the inner bottom of described fixed table 9, deflector 11 is opened at the bottom of described fixed table 9, and the inner side of described shell 7 is close to fixed table 9 The ...

Embodiment 2

[0021] Such as Figure 1-3 As shown, a water removal device before the treatment of organic waste includes a conveying assembly 1, and the conveying assembly 1 includes a fixed support 2, a feed hopper 3, an auger 4, a first motor 5 and a pipeline 6, and the A feed hopper 3 is installed on one side of the top of the fixed bracket 2, an auger 4 is installed on the outer side of the feed hopper 3 through the fixed bracket 2, and a first motor 5 is installed on the lower side of the auger 4, A pipeline 6 is installed on the upper side of the auger 4, a casing 7 is installed at the bottom of the pipeline 6, and a water removal assembly 8 is installed on the top side of the inner top of the casing 7, and the water removal assembly 8 includes Fixed table 9, fan 10 and deflector 11, fan 10 is installed at the inner bottom of described fixed table 9, deflector 11 is opened at the bottom of described fixed table 9, and the inner side of described shell 7 is close to fixed table 9 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com