Method and device for variable pressure difference measurement

The technology of a metering device and metering method is applied in the direction of detecting fluid flow by measuring pressure difference, volume/mass flow generated by mechanical effects, etc., which can solve the problems of insufficient reliability and achieve improved reliability, improved metering range, and expanded selection range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

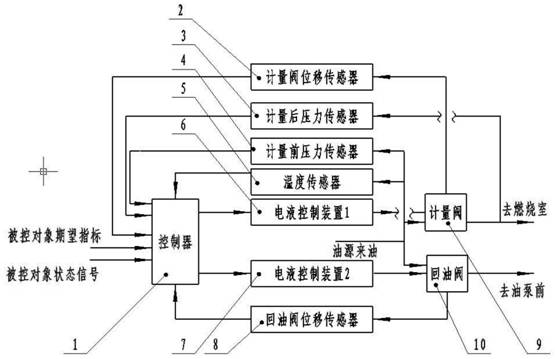

[0037] Such as figure 1 As shown, the method is applied to a variable pressure differential metering device, which includes a controller 1, a metering valve displacement sensor 2, a post-measurement pressure sensor 3, a pre-measurement pressure sensor 4, a temperature sensor 5, a first electro-hydraulic control Device 6 , second electro-hydraulic control device 7 , oil return valve displacement sensor 8 , metering valve 9 , and oil return valve 10 .

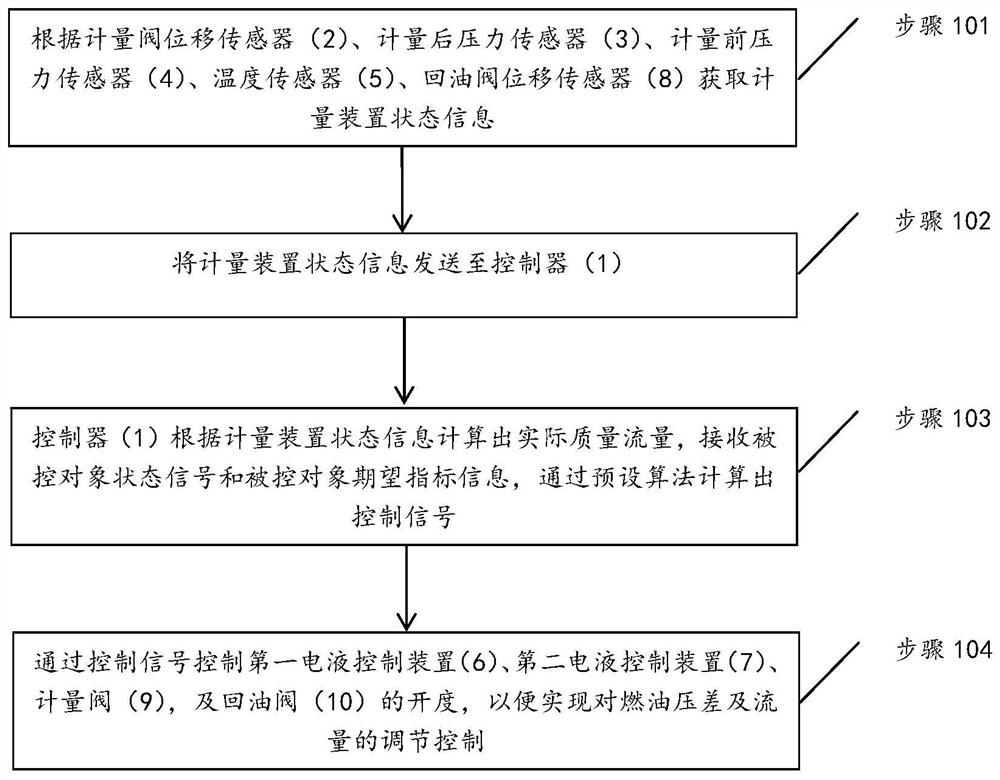

[0038] figure 2 A schematic flow chart of the variable pressure difference measurement method provided in Embodiment 1 of the present invention, as figure 2 As shown, the variable pressure difference measurement method includes:

[0039]Step 101: Obtain the status information of the metering device according to the metering valve displacement sensor 2, the post-metering pressure sensor 3, the pre-metering pressure sensor 4, the temperature sensor 5, and the oil return valve displacement sensor 8;

[0040] Step 102: Send the ...

Embodiment 2

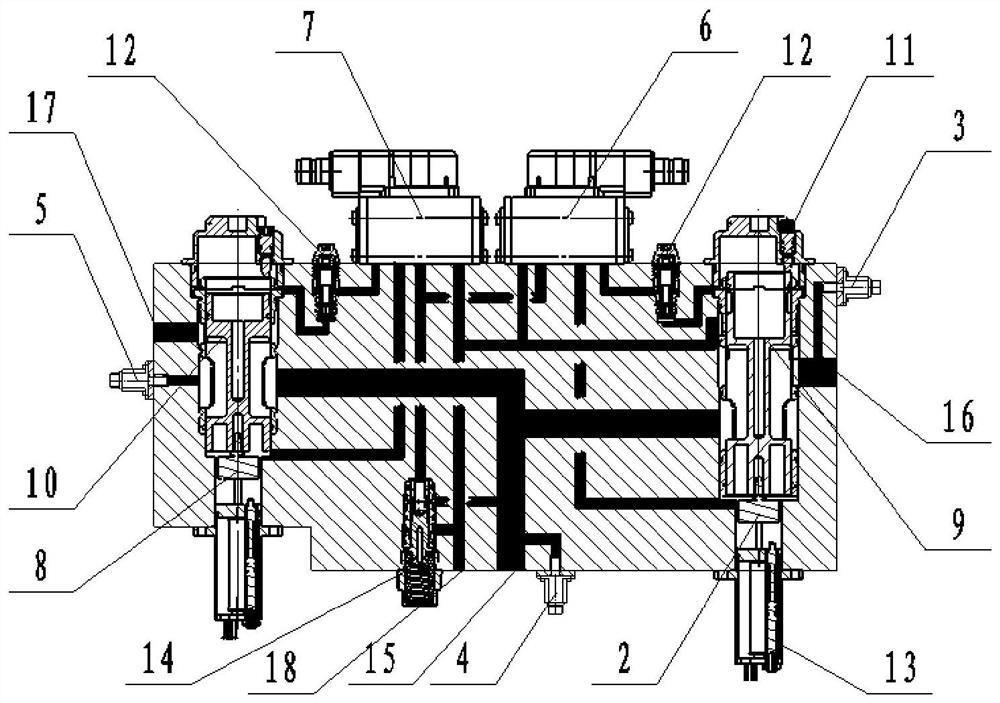

[0053] image 3 Schematic diagram of the structure of the variable pressure differential metering device provided by the present invention. combine figure 1 and image 3 As shown, a variable pressure difference metering device provided by the present invention includes a controller 1, a metering valve displacement sensor 2, a pressure sensor 3 after metering, a pressure sensor 4 before metering, a temperature sensor 5, a first electro-hydraulic control device 6, The second electro-hydraulic control device 7, oil return valve displacement sensor 8, metering valve 9, oil return valve 10, wherein:

[0054] Metering valve displacement sensor 2, post-measurement pressure sensor 3, pre-measurement pressure sensor 4, temperature sensor 5, oil return valve displacement sensor 8, first electro-hydraulic control device 6, second electro-hydraulic control device 7 are connected with controller 1, Metering valve 9 and oil return valve 10 are connected.

[0055] Exemplarily, the first ...

Embodiment 3

[0062] combine figure 1 and image 3 As shown, another variable pressure difference metering device provided by the present invention, wherein the constant pressure valve 14 cooperates with the low pressure oil outlet 18 of the constant pressure valve to provide stable servo oil for the variable pressure difference metering device, reducing the impact of fuel pressure fluctuations on control accuracy The influence of fuel metering improves the accuracy of fuel metering.

[0063] The fuel pump provides fuel through the fuel inlet 15, and after being metered by the variable pressure difference metering device, the fuel outlet 16 provides accurately metered fuel to the combustion chamber of the engine.

[0064] The metering valve displacement sensor 2, the pressure sensor after metering 3, the pressure sensor before metering 4, the temperature sensor 5, and the oil return valve displacement sensor 8 will measure the pressure before and after the metering valve of the fuel meteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com