Refined measurement method for solid propellant aluminum agglomerated particles

A technology for solid propellant and agglomeration of particles, which can be used in measurement devices, particle and sedimentation analysis, particle size analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

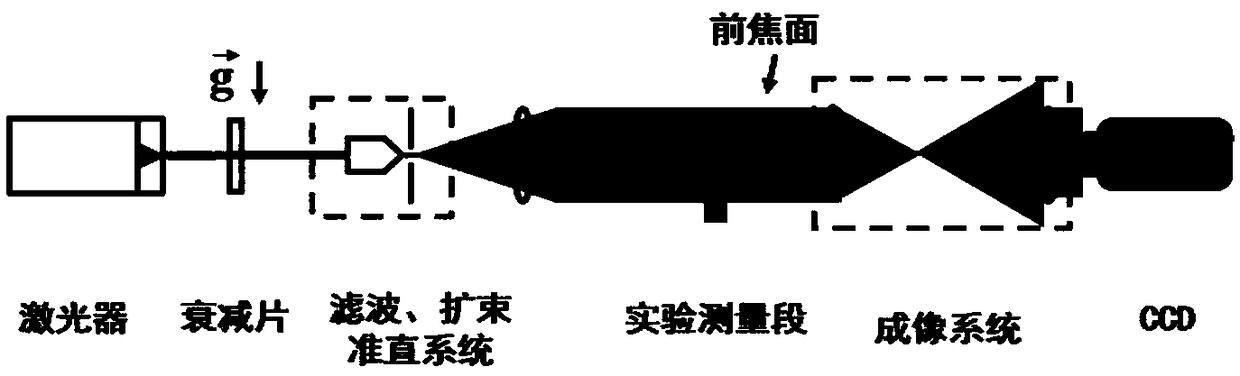

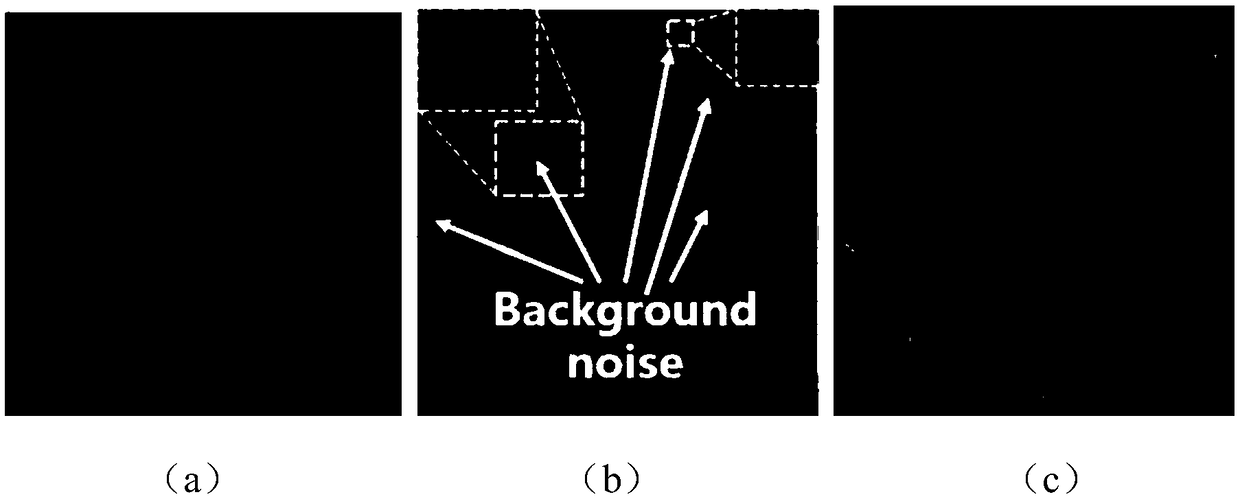

Method used

Image

Examples

Embodiment

[0060] The experimental measurement uses aluminum-containing solid propellant, the content of aluminum powder is 18%, and the size of the propellant sample is 5mm×5mm×10mm. In view of the large particle size distribution of aluminum combustion particles (1 ~ 1000μm), two imaging systems with magnifications (1.1× and 2.7×) were used respectively, and the corresponding measurement areas were 11.63mm*8.73mm and 4.74mm* 3.56mm.

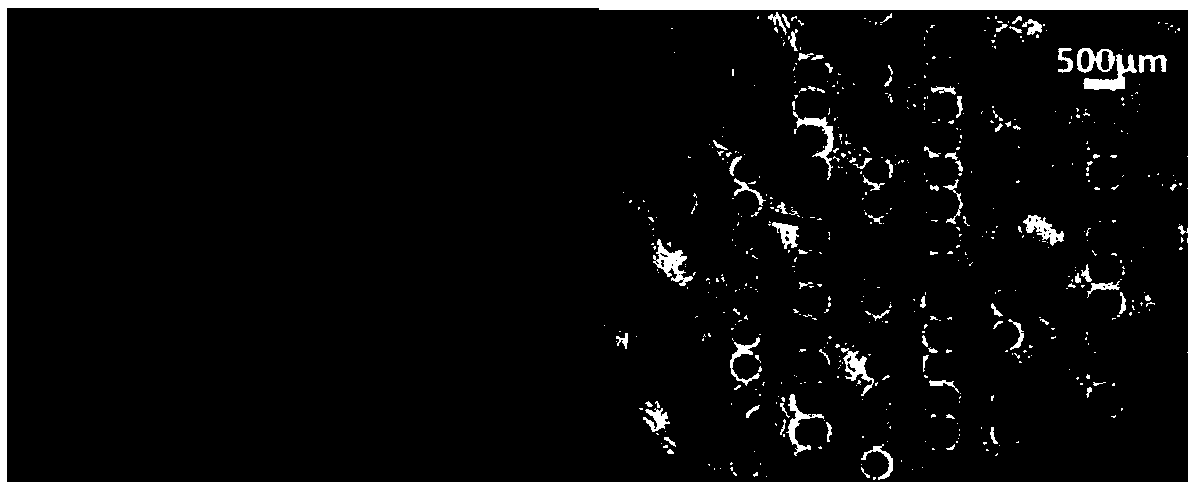

[0061] Reconstruct the holographic images of all effective metal particle combustion measured during the propellant combustion process, and use the image processing algorithm of the present invention to obtain particle size information of all particles on the combustion surface and in the combustion field from the reconstructed images. Among them, 11420 and 7152 particles were extracted from the reconstructed images of two propellant Cases (Case1 and Case2), respectively. A typical reconstructed holographic image of metal burning particles such as Figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com