Detection system and method of structural adhesive based on machine vision

A detection system and machine vision technology, used in instruments, measuring devices, scientific instruments, etc., can solve the problems of worker fatigue, low efficiency, time-consuming and labor-intensive, and achieve the effect of facilitating secondary processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

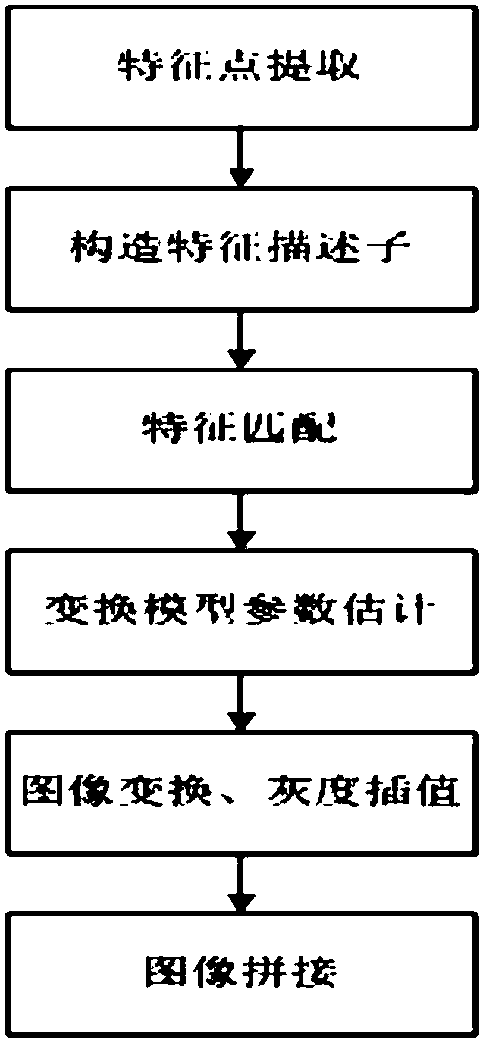

[0025] In this system, the PLC triggers the camera and light source, then collects the image, sends the obtained image to the industrial computer for image stitching and defect detection algorithm processing, saves the obtained defect, and displays the defect through the interface.

[0026] The image acquisition module integrates the prism and the camera based on the principle of prism light path propagation and camera imaging. First of all, the glued surface of the glass door passes through the refraction and reflection of the prism, which makes the light path turn and propagate to the observed surface of the prism. Imaging, so as to realize the whole image acquisition process.

[0027] The camera outputs the collected image signal to the PLC industrial computer. The PLC industrial computer is equipped with a processor for image processing, a memory for storing images, and a display for displaying results. The camera outputs image signals to the processor, and the processor o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com