Busway

A technology for bus ducts and clamping components, applied in the field of bus ducts, can solve problems such as poor heat dissipation effect, and achieve the effects of reducing the incidence of accidents, improving safety and stability, and reducing siltation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

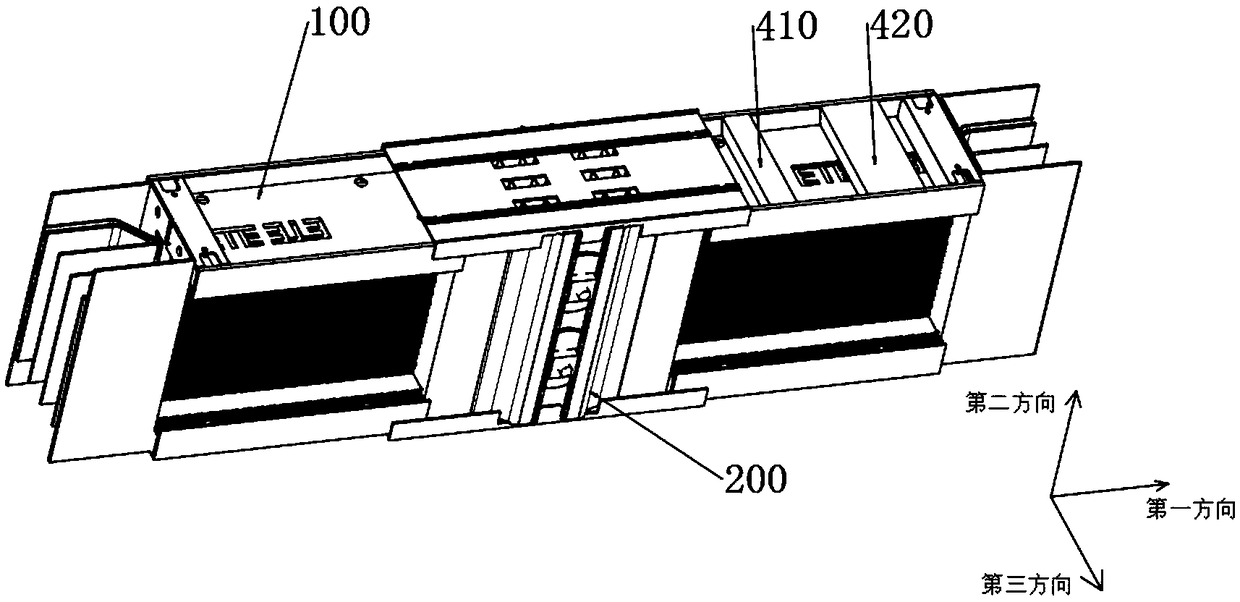

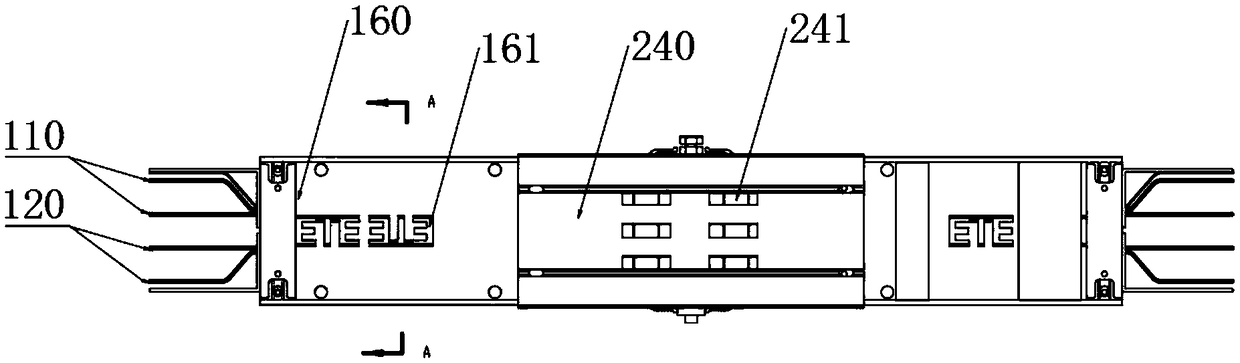

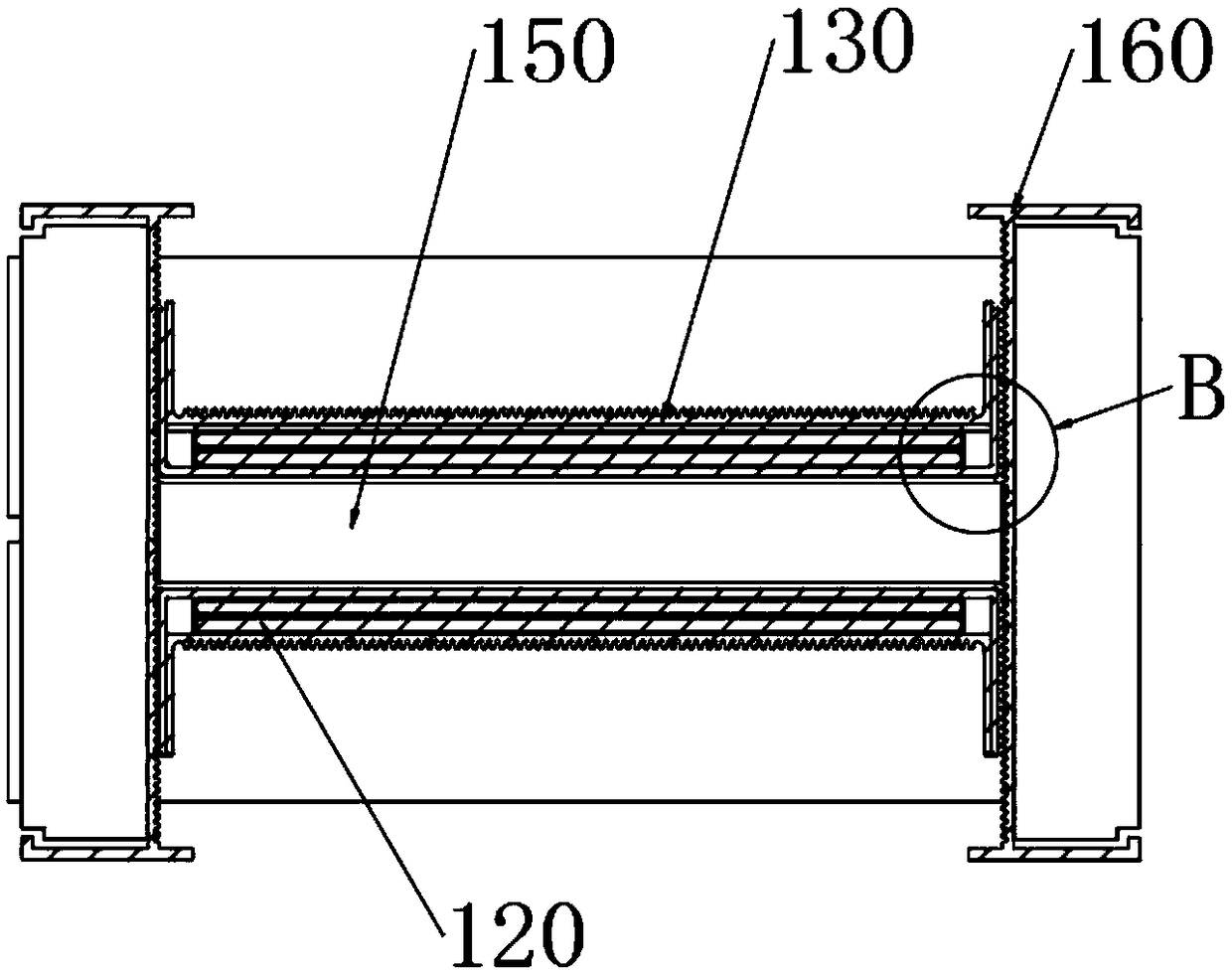

[0048] Such as Figure 1-Figure 3 As shown, the busway provided by the embodiment of the present invention includes: a busway unit 100, the busway unit 100 includes a housing, and a first conductor group 110 and a second conductor group 120 extending along a first direction, and the housing includes two Clamping assembly 130, the two clamping assemblies 130 respectively clamp and fix the first conductor set 110 and the second conductor set 120; the housing includes two spacers 140, the spacer 140 is located between the two clamping assemblies 130, Two spacers 140 are distributed at one end and the other end of the clamp assembly 130 at intervals, so that the two clamp assemblies 130 and the two spacers 140 enclose a heat dissipation channel 150 extending along the second direction; Two cover plates 160 arranged in parallel and at intervals, that is, an upper cover plate and a lower cover plate, the cover plates 160 are respectively connected with the two clamping assemblies 13...

Embodiment 2

[0073] Such as Figure 11-Figure 12 As shown, the difference from Embodiment 1 is that the number of heat dissipation through holes 231 on each heat dissipation part of the heat dissipation element 230 is one, and the edge of the second heat dissipation hole 241 of the connecting cover 240 extends toward the bottom surface. The barrel 242 and the inserting barrel 242 are used for inserting into the heat dissipation through hole 231 , and the outer wall of the inserting barrel 242 is in close contact with the inner wall of the heat dissipation through hole 231 .

[0074] Such as Figure 13 As shown, during installation, the heat dissipation through hole 231 of the heat sink 230 can be inserted on the socket 242 of the lower connection cover 240 first, and then the upper connection cover 240 is installed, and the insertion socket 242 on the upper connection cover 240 is plugged into the heat sink. At the other port of the through hole 231, external dust or water flows into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com