One-way valve type powder spraying and wax injecting integrated type structure

A one-way valve, integrated technology, applied in the direction of injection device, liquid injection device, etc., can solve the problems of affecting the pass rate of wax mold molding, uncontrollable amount of powder spraying, uneven powder spraying, etc., to save labor costs. , spray powder uniformly, improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, and the implementation scope of the present invention is not limited thereto.

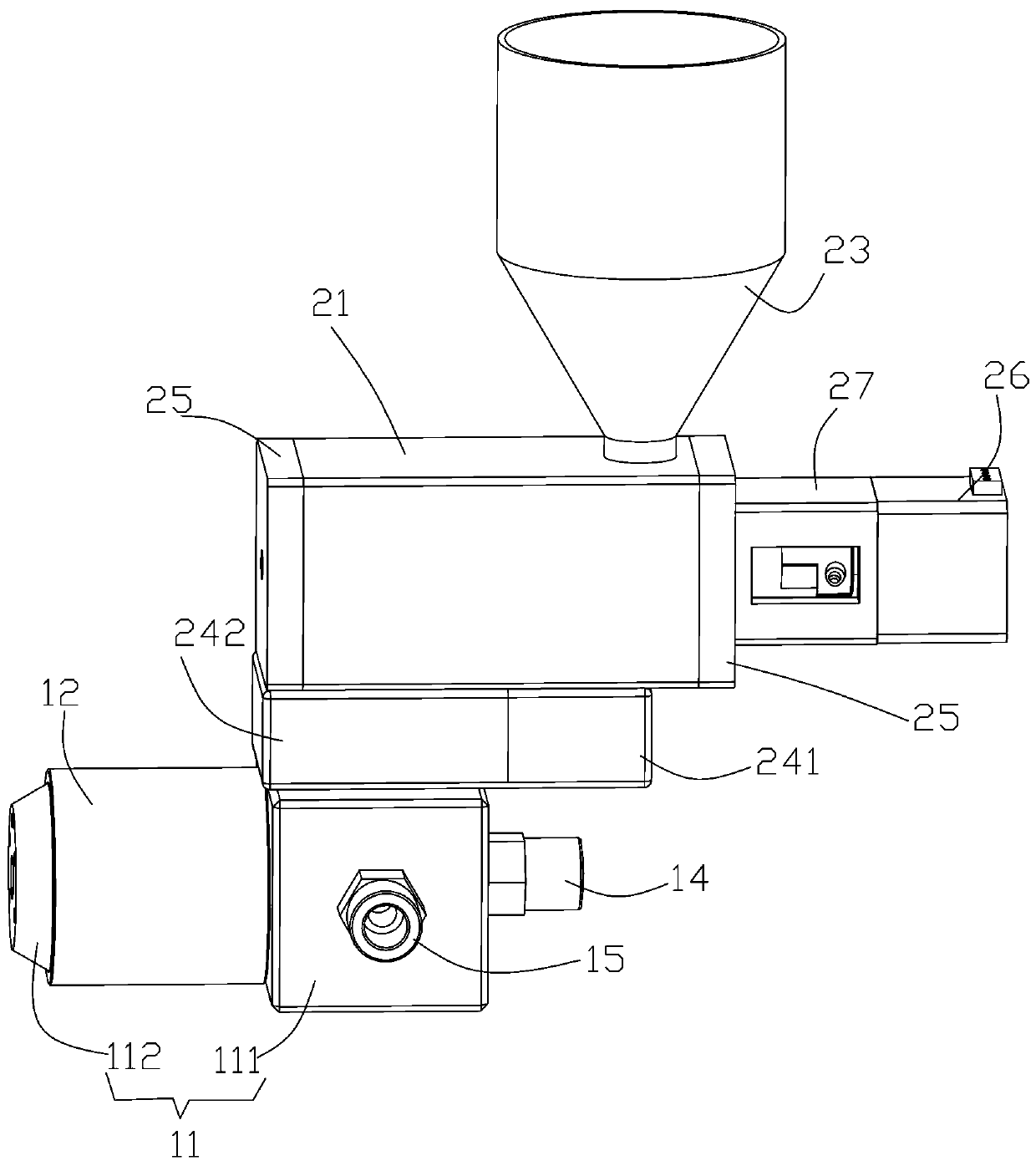

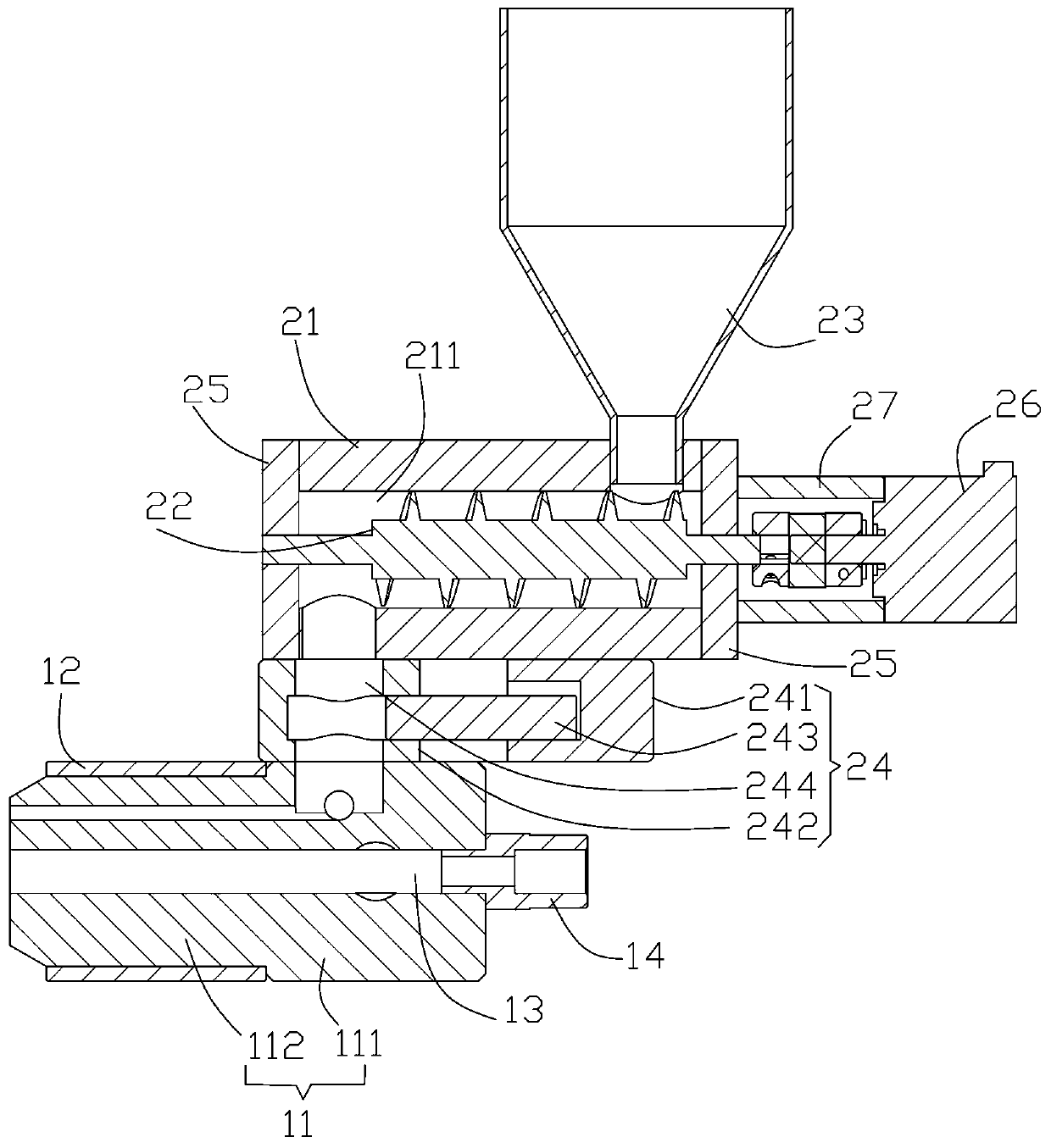

[0018] like Figure 1 to Figure 4 As shown, the one-way valve-type powder spraying and wax injection integrated structure described in this embodiment includes a screw powder feeding device and a nozzle composite device. The screw powder feeding device is used to quantitatively deliver powder for the nozzle composite device. The above nozzle composite device is used for powder spraying and wax injection for the mould;

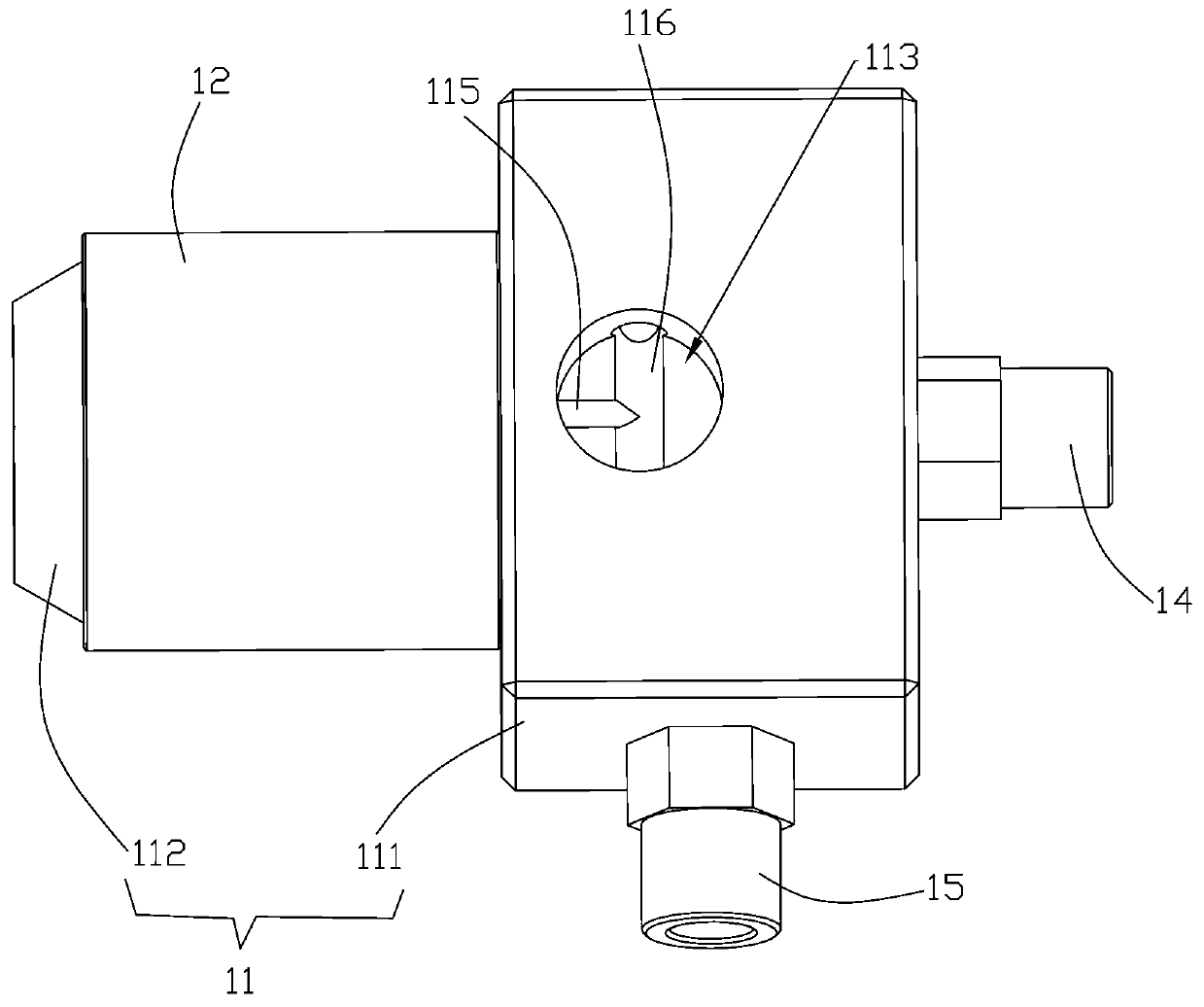

[0019] The nozzle compounding device includes a feed nozzle head 11 and a heating tube 12, the feed nozzle head 11 includes a rectangular parallelepiped first nozzle part 111 and a cylindrical second nozzle part 112, the feed nozzle head 11 is set There is a first through hole 13, the first through hole 13 runs through the first nozzle part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com