Automatic assembly equipment for small circuit breakers

A small circuit breaker and automatic assembly technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of low assembly efficiency, high product scrap rate, product quality easily affected by objective factors, etc., and achieve high assembly efficiency. , the effect of high quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

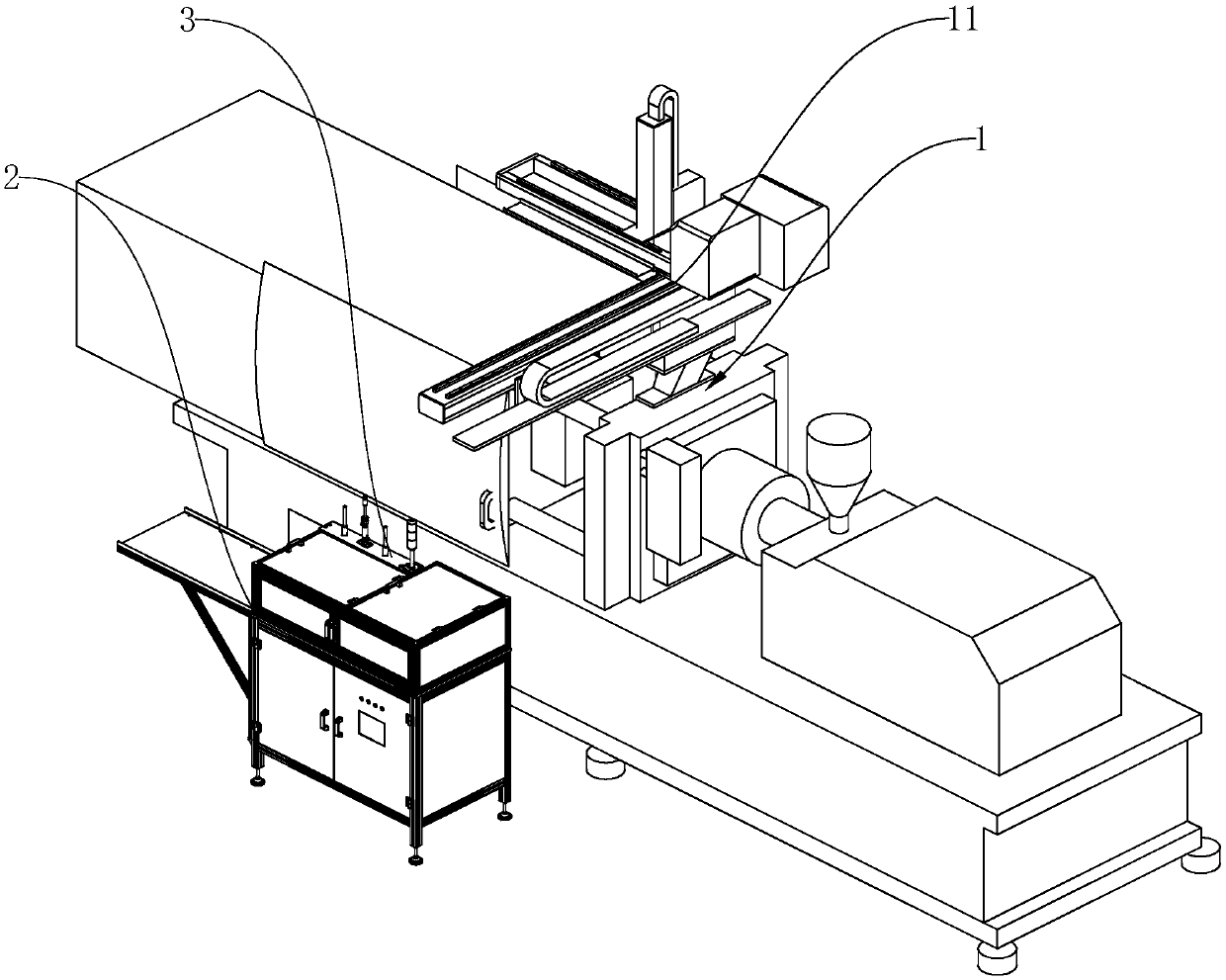

[0033] Embodiment 1: As shown in the figure, an automatic assembly equipment for miniature circuit breakers, including

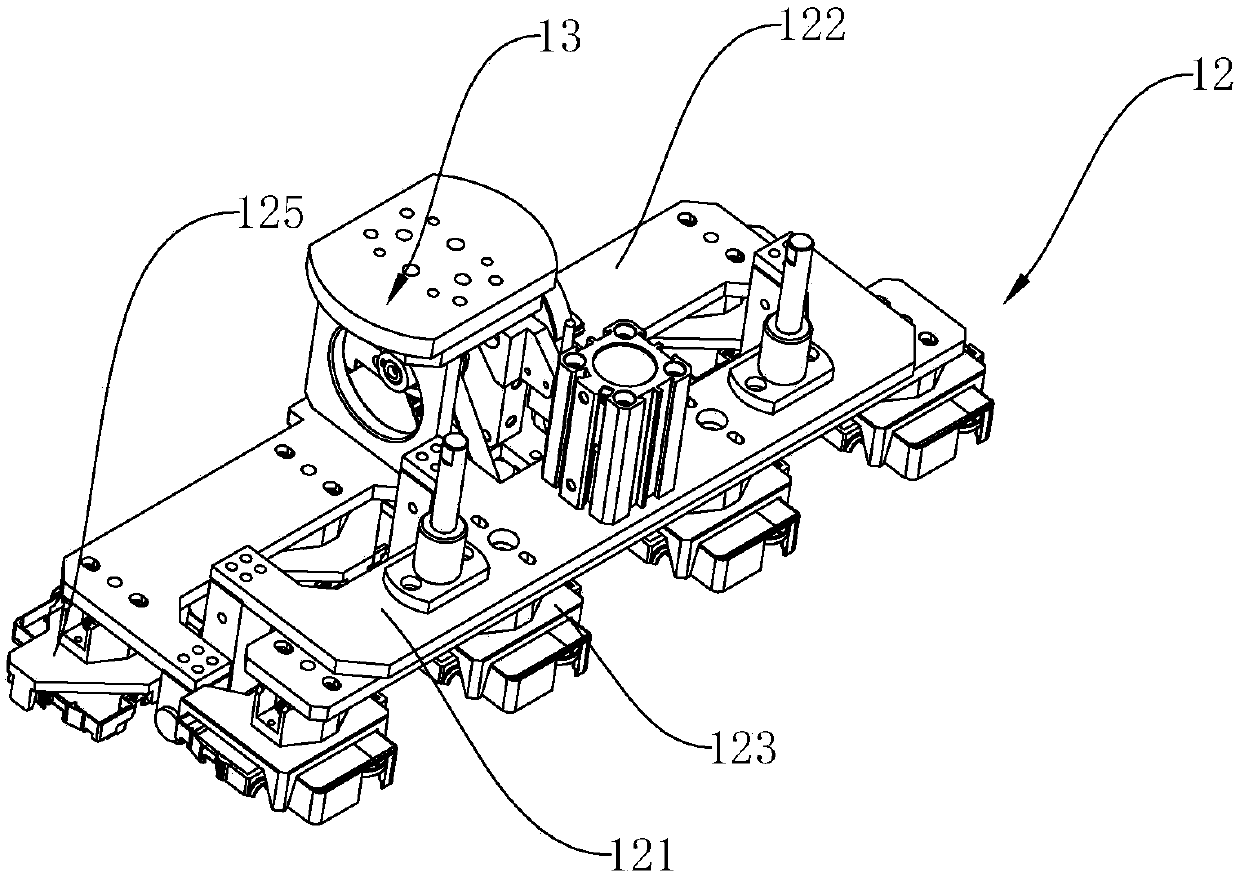

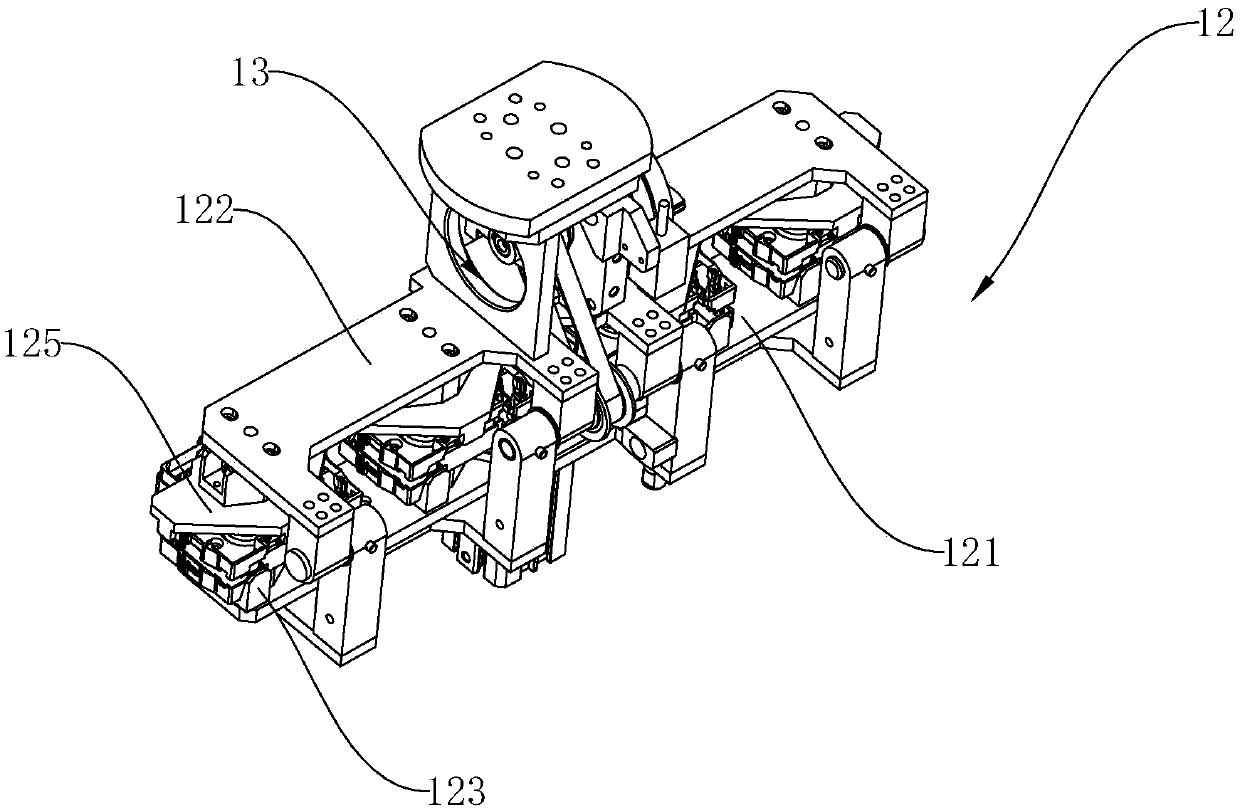

[0034] Assembly device 1, the assembly device 1 is composed of a mechanical arm 11 with six degrees of freedom and an assembly jig 12 connected to the mechanical arm 11, the assembly jig 12 is used to take out the molded small The first casing of the circuit breaker and the second casing of the miniature circuit breaker, and assembling them into one;

[0035] Combined installation platform 2, combined installation platform 2 is fixed with the first side plate 21 and the second side plate 22 along the longitudinal direction, the first side plate 21 and the second side plate 22 are arranged oppositely, and form a small-sized space between the two for arrangement. Movement space 23 for circuit breaker movement;

[0036] Clamping mechanism 3, the clamping mechanism 3 is arranged on the assembly platform 2 to receive the small circuit breaker transferred from th...

Embodiment 2

[0040] Embodiment 2: As shown in the figure, an automatic assembly equipment for a miniature circuit breaker, including

[0041] Assembly device 1, the assembly device 1 is composed of a mechanical arm 11 with six degrees of freedom and an assembly jig 12 connected to the mechanical arm 11, the assembly jig 12 is used to take out the molded small The first casing of the circuit breaker and the second casing of the miniature circuit breaker, and assembling them into one;

[0042] Combined installation platform 2, combined installation platform 2 is fixed with the first side plate 21 and the second side plate 22 along the longitudinal direction, the first side plate 21 and the second side plate 22 are arranged oppositely, and form a small-sized space between the two for arrangement. Movement space 23 for circuit breaker movement;

[0043] Clamping mechanism 3, the clamping mechanism 3 is arranged on the assembly platform 2 to receive the small circuit breaker transferred from t...

Embodiment 3

[0050] Embodiment 3: As shown in the figure, an automatic assembly equipment for a miniature circuit breaker, including

[0051] Assembly device 1, the assembly device 1 is composed of a mechanical arm 11 with six degrees of freedom and an assembly jig 12 connected to the mechanical arm 11, the assembly jig 12 is used to take out the molded small The first casing of the circuit breaker and the second casing of the miniature circuit breaker, and assembling them into one;

[0052] Combined installation platform 2, combined installation platform 2 is fixed with the first side plate 21 and the second side plate 22 along the longitudinal direction, the first side plate 21 and the second side plate 22 are arranged oppositely, and form a small-sized space between the two for arrangement. Movement space 23 for circuit breaker movement;

[0053] Clamping mechanism 3, the clamping mechanism 3 is arranged on the assembly platform 2 to receive the small circuit breaker transferred from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com