A cheese radio frequency dryer capable of fast feeding and discharging

A radio frequency dryer, radio frequency drying technology, applied in the processing of textile materials, processing textile material carriers, textiles and papermaking, etc., can solve the problem of inconvenient cheese discharge, excessive time consumption, and no limit function of the conveyor belt, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

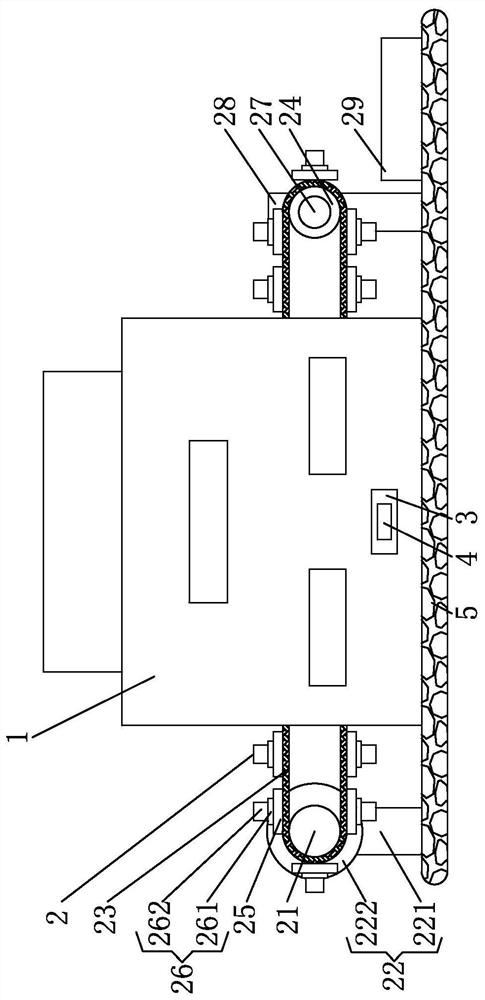

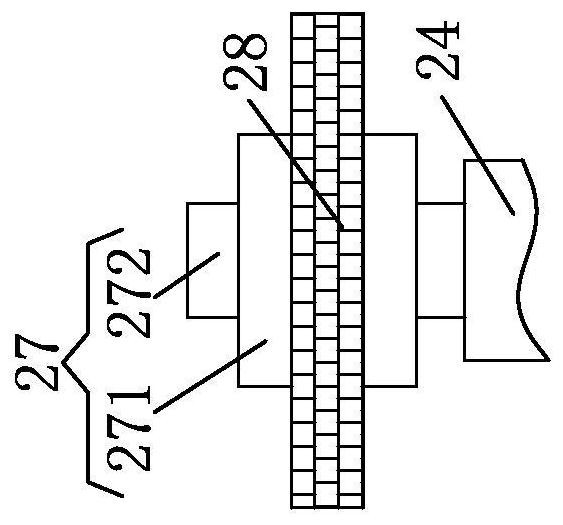

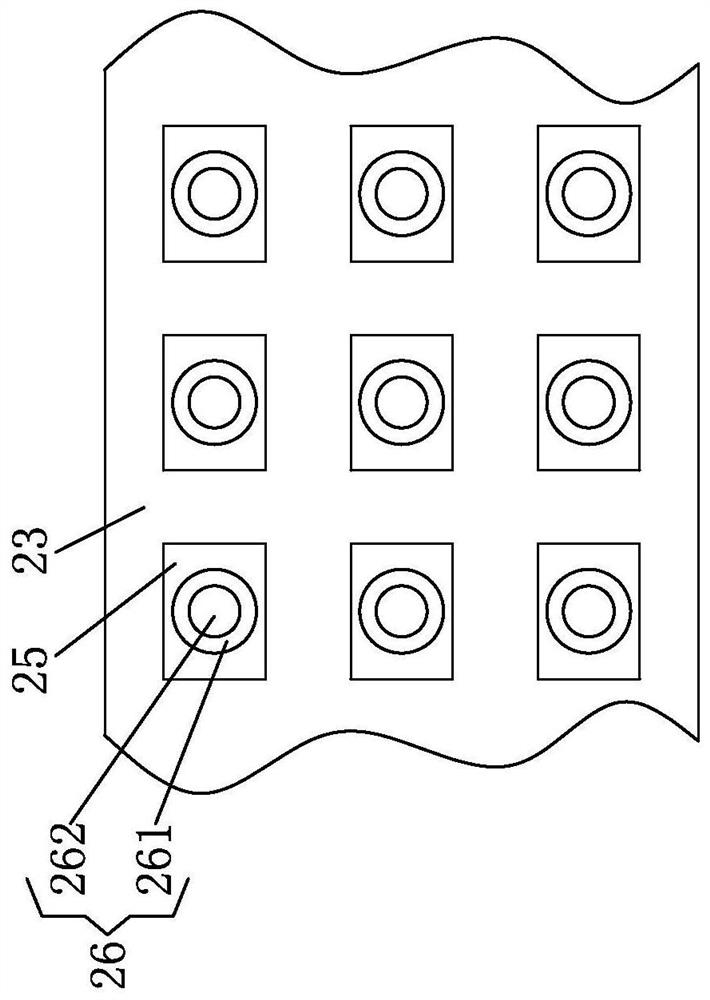

[0024]Such asFigure 1-3In the present invention, the present invention provides a technical solution: a cartridge yarn yarn grunger that can be rapidly discharged, including the radio frequency drying mechanism 1, and the internal portion of the radio frequency drying mechanism 1 is provided with a transfer mechanism 2, and radio frequency bake The drying mechanism 1 is provided at the upper surface of the base 5, and the upper surface of the base 5 is fixedly coupled to the bottom end of the conveying mechanism 2, and the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com