High-protruding object periphery waterproof treatment device and method for steel structure roof

A technology of waterproof treatment and high protrusions, applied in the direction of roof, roof drainage, roof covering, etc., can solve problems such as roof leakage, masonry mortar and lock seal paste cracks, poor waterproof performance, etc., to avoid heat expansion and cold Shrinkage, water leakage hidden trouble solution, good waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation of the invention will be further described below in conjunction with the accompanying drawings.

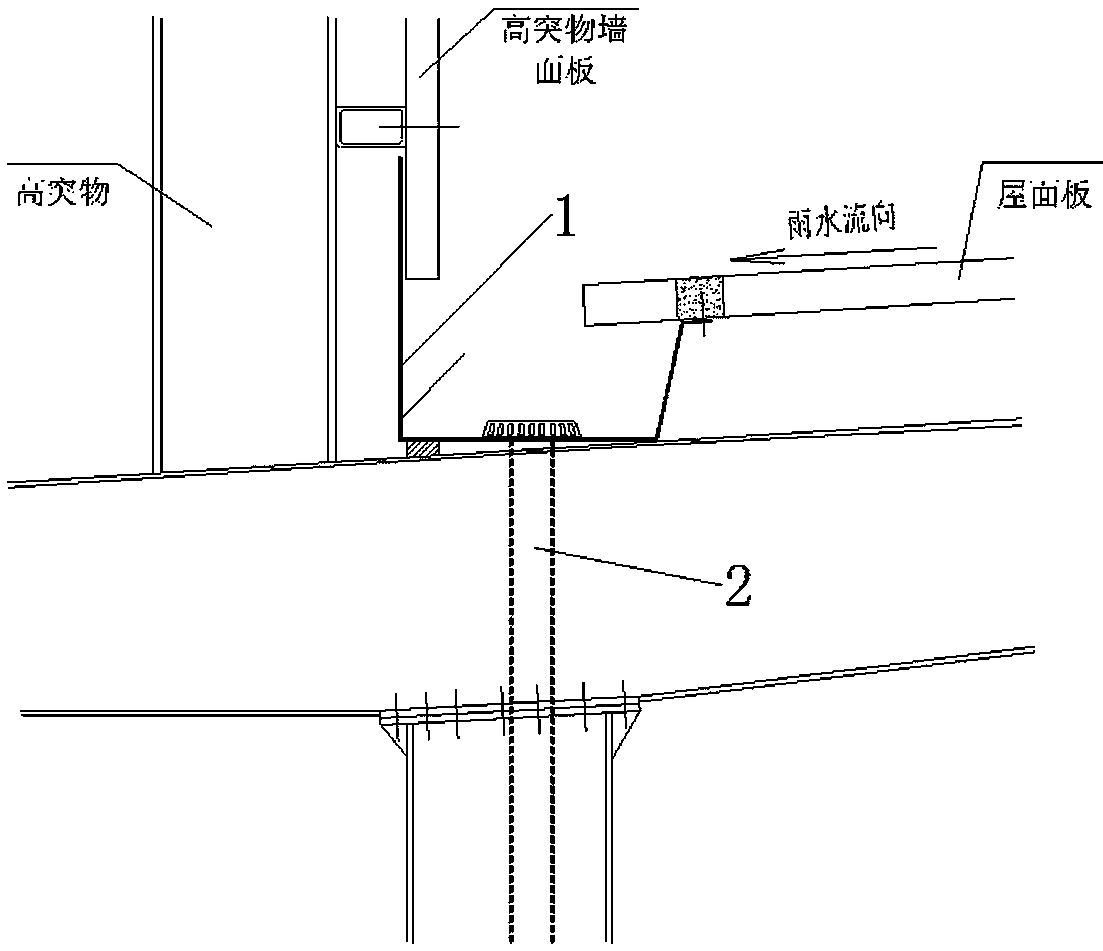

[0027] Such as figure 1 As shown, the waterproof treatment device around the high protrusions of the steel structure roof of the present invention includes a waterproof structure.

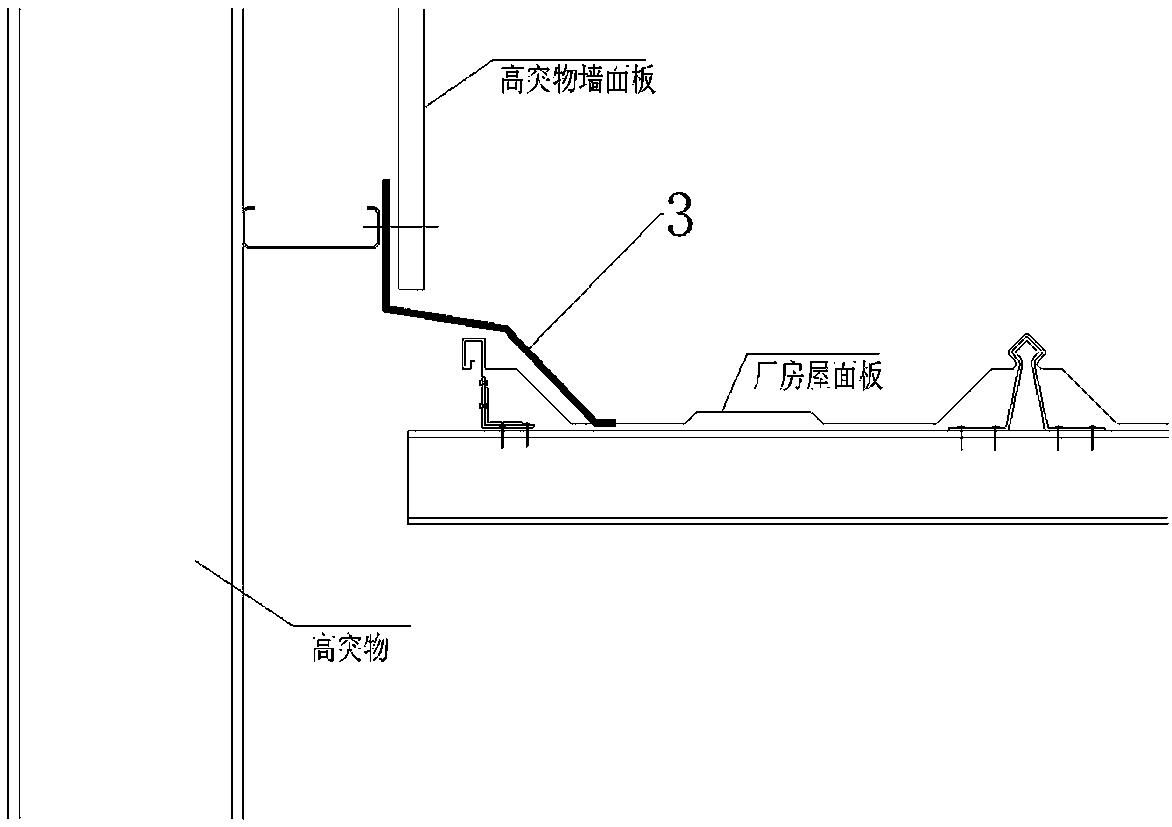

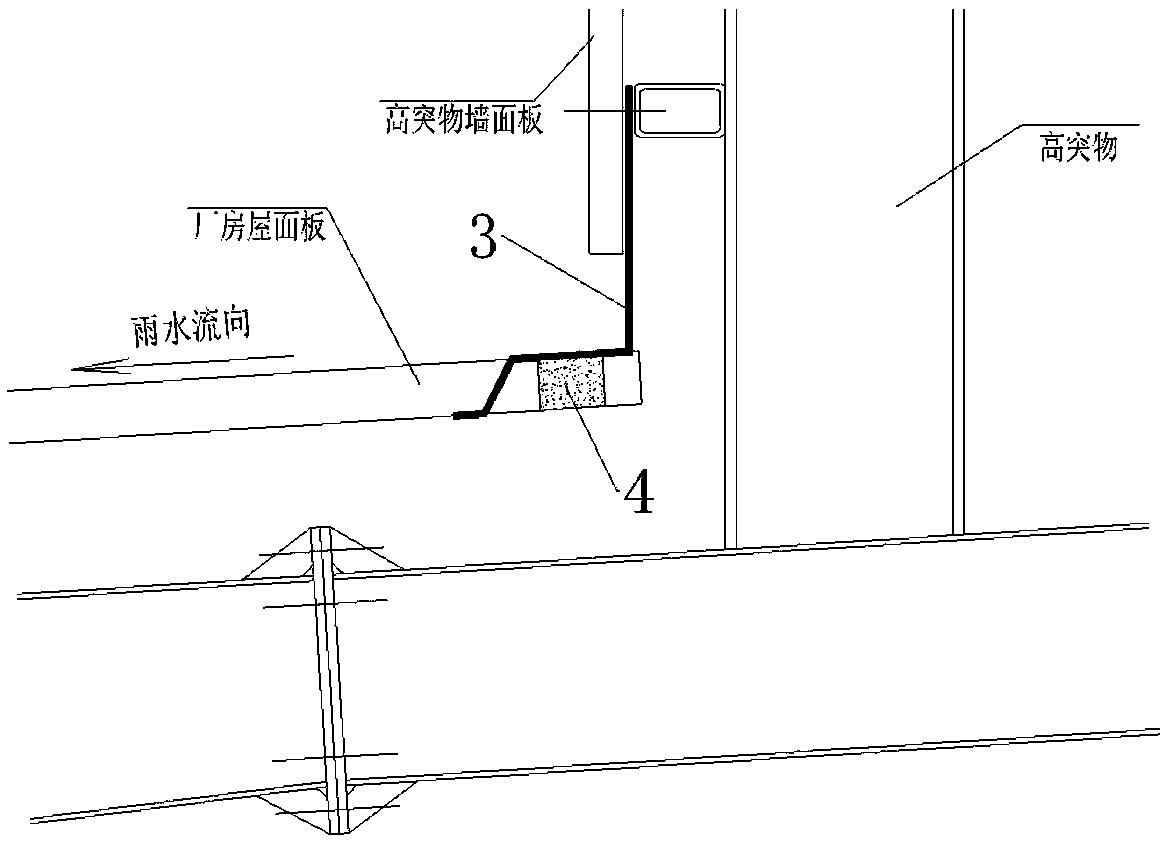

[0028] Such as Figure 1-3 As shown, the waterproof structure includes a gutter 1, a downpipe 2, a waterproof edge 3 and a waterproof plug 4; the gutter 1 is an inner wall type gutter, and the gutter 1 is installed between the roof protrusion and the roof panel. The gutter 1 is welded by white iron sheet. The cross section of the gutter 1 is U-shaped. The gutter 1 is arranged horizontally in the direction of the roof ridge of the house. The downpipe 2 is a plastic pipe fitting, the downpipe 2 runs through the lower end of the gutter 1, and the bottom end of the downpipe 2 communicates with the gutter on the ground of the house; the waterproof edge 3 is an L-shaped m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com