Pump body assembly and rotor compressor

A technology of rotor compressors and components, applied in the field of compressors, which can solve problems such as abnormal reliability, limited performance of compressors, wear of sliding vanes and cylinder sliding vane grooves, etc., to reduce leakage losses, avoid abnormal wear, reduce gap effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

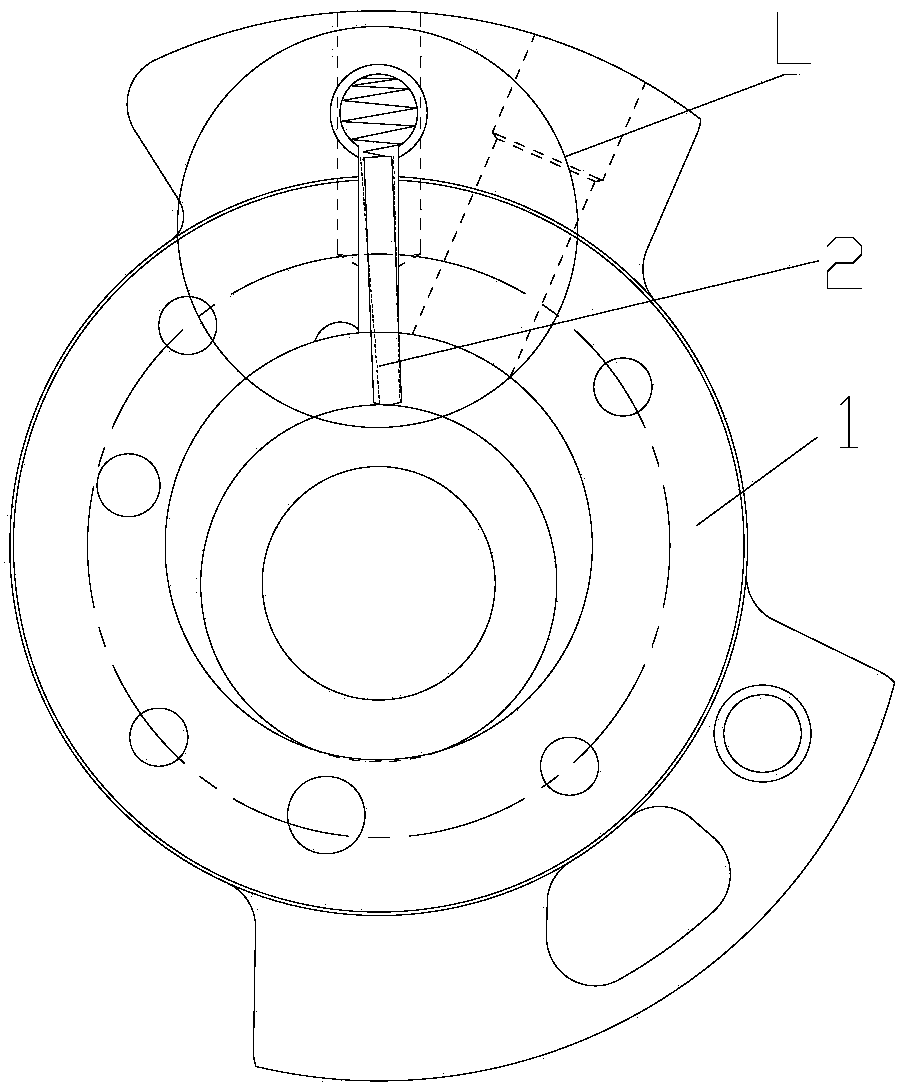

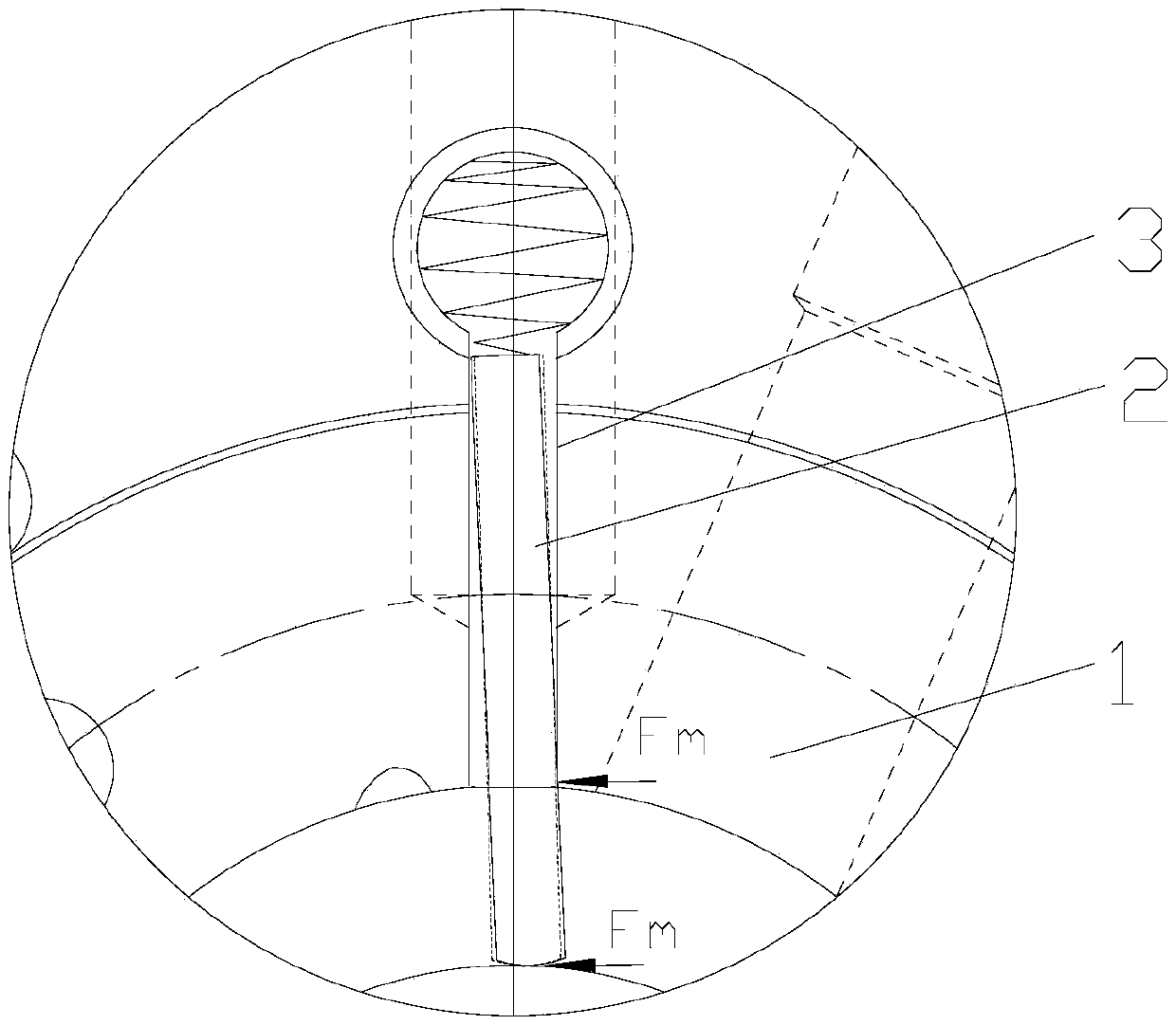

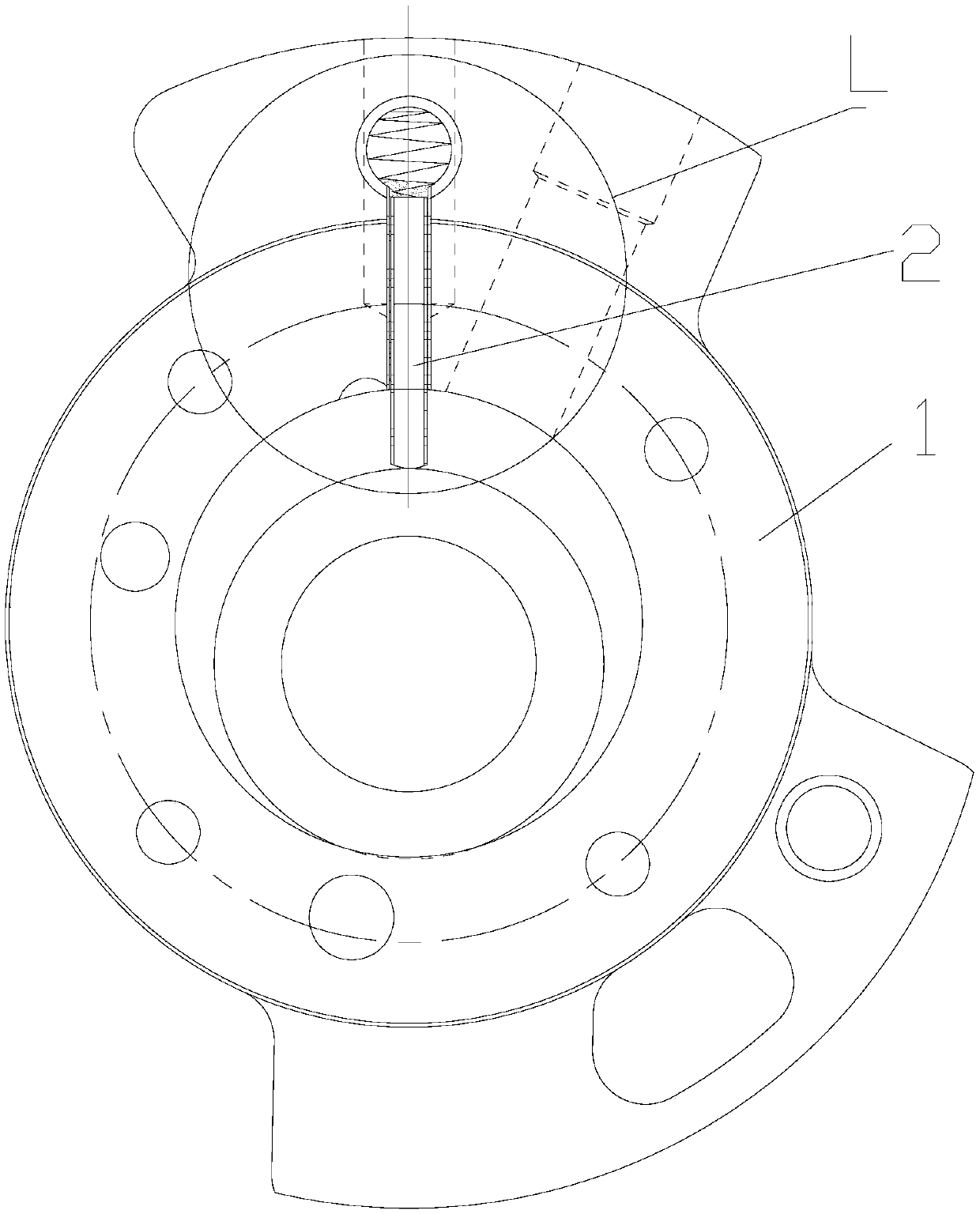

[0023] See also Figure 1 to Figure 2 As shown, the existing compressor includes a pump body assembly. The pump body assembly includes a cylinder 1 and a sliding plate 2. The cylinder 1 is provided with a sliding plate groove 3, and the sliding plate 2 is slidably arranged in the sliding plate groove 3. When the compressor is running, the crankshaft drives the rollers to make a rotary motion. The sliding vane 2 closes to the roller and moves back and forth in the sliding vane groove 3 under the action of the spring, and cooperates with other pump body components to form a workable sealed environment.

[0024] In order to ensure the energy efficiency of the compressor, it is necessary to ensure that there is little gas leakage, that is, the roller and the sliding plate 2 are attached, and the gap between the sliding plate 2 and the cylinder 1 groove is as small as possible. When only the oil film is retained to ensure that the sliding plate 2 can operate, the sliding The leakage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com