High-efficiency waste pyrolysis gasifier

A technology of pyrolysis gasification and gasification furnace, applied in incinerators, lighting and heating equipment, combustion methods, etc., can solve problems such as incomplete pyrolysis of garbage, achieve complete pyrolysis and increase calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

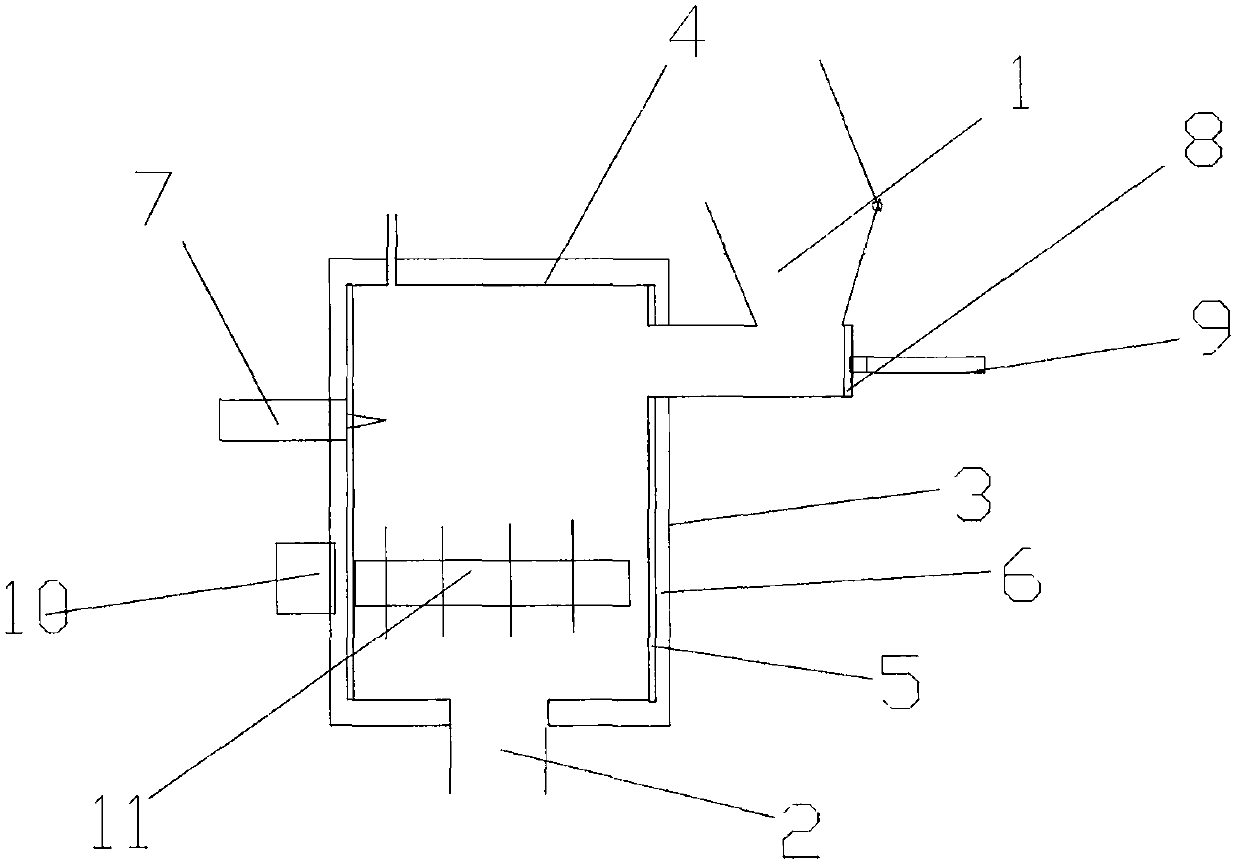

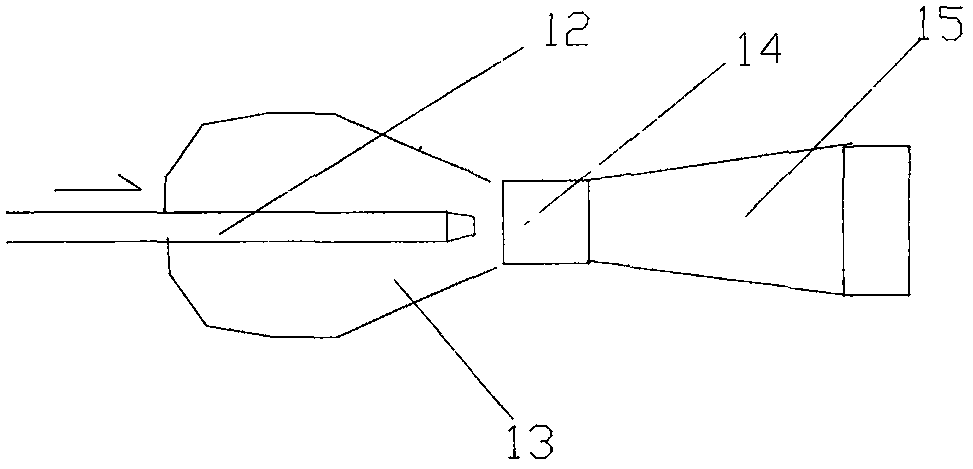

[0019] Such as Figure 1-2 As shown, a high-efficiency garbage pyrolysis gasifier includes a gasifier body, the gasifier body is provided with a feed port 1, and the feed port 1 is connected to a pushing device, and the gasifier body There is a stirring device inside, and the bottom of the gasifier body is provided with a slag outlet 2, and the gasifier body includes a pyrolysis outer cylinder 3 and a pyrolysis inner cylinder 4, and the pyrolysis inner cylinder is formed to contain A pyrolysis chamber for putting garbage, a heating device is arranged between the pyrolysis outer cylinder and the garbage pyrolysis inner cylinder, the heating device includes radiation tubes 5 arranged in multiple layers along the outer wall of the inner cylinder, and also includes carbon black injection device, the carbon black injection device communicates with the pyrolysis inner cylinder, the top of the gasification furnace body is provided with a gas outlet, and an insulation layer 6 is forme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com