High-temperature type double-channel intelligent dryer

A dual-channel, dryer technology, used in dryers, drying, drying gas layout, etc., can solve problems such as serious energy loss, serious environmental pollution, and easy occurrence of stuffiness, so as to improve quality and output, reduce Energy loss, the effect of avoiding energy loss and waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

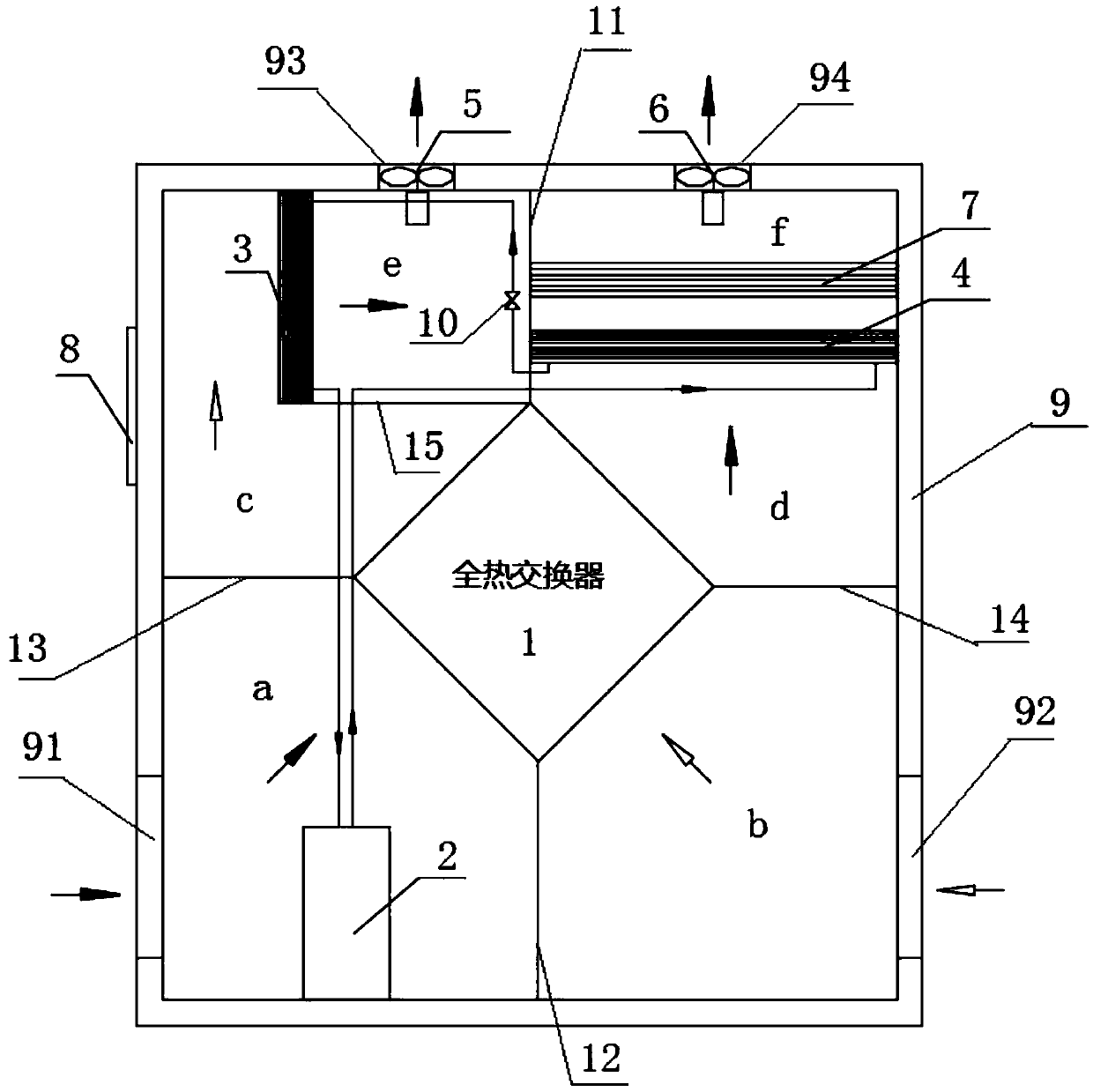

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, its specific implementation will be described in detail below in conjunction with the accompanying drawings:

[0029] see figure 1 , the best embodiment of the present invention, a high-temperature dual-channel intelligent dryer, including a housing 9, a total heat exchanger 1, a compressor 2, an evaporator 3, a condenser 4, a frequency conversion dehumidification fan 5, a blower 6. PTC ceramic heater 7 and controller 8.

[0030] The left and right side walls of the casing 9 are provided with a fresh air outlet 91 and a return air outlet 92 correspondingly, and the top plate of the casing 9 is provided with an air outlet 93 and an air supply outlet 94; strainer.

[0031] The total heat exchanger 1 is located in the middle of the housing 9, an upper partition 11 is arranged between the top of the total heat exchanger 1 and the top plate of the housing 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com