Facility agriculture root vegetable sampler

A technology for root vegetables and facility agriculture, applied in the field of root vegetable samplers in facility agriculture, can solve the problems affecting the accuracy and reliability of final detection data, uneven sample shape and volume, long time consumption, etc., and shorten the oxidation time. time, increased convenience, time saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

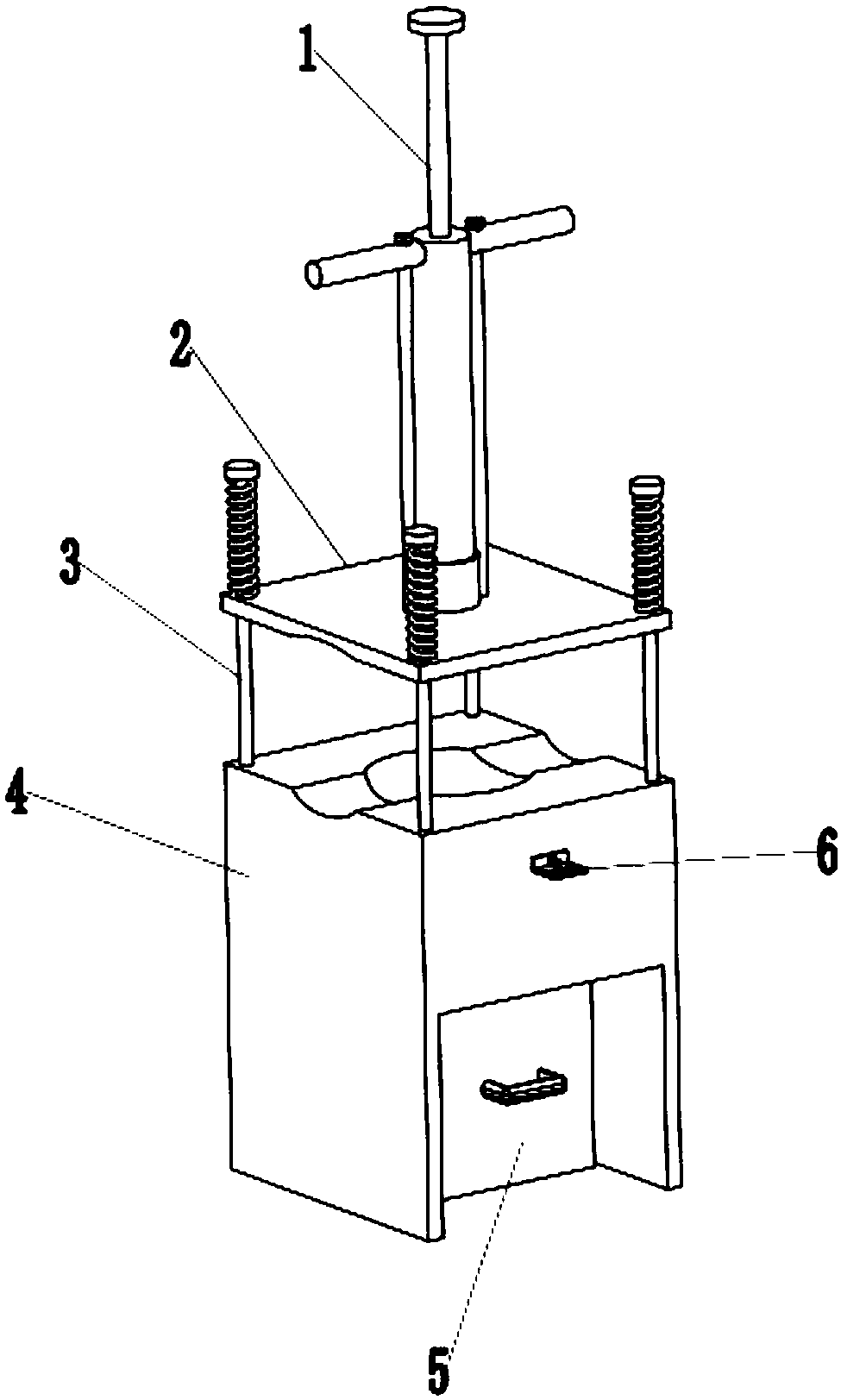

[0041] Such as figure 1 As shown, a root vegetable sampler for facility agriculture includes a cutting cylinder 1, a vegetable pressing plate 2, a fixed table 4, and a material box 5. The bottom of the fixed table 4 is connected with the material box 5, and the fixed table 4 is provided with The vegetable outlet hole 405 communicated with the material box 5, the top of the fixed table 4 is provided with a vegetable pressing plate 2, and the middle part of the vegetable pressing plate 2 is provided with a vegetable cutting hole 207 aligned with the vegetable outlet hole 405 position up and down , the corners of the pressing plate 2 are connected to the fixed table 4 through the connecting rod 3, the upper end of the pressing plate 2 is provided with a cutting cylinder 1, and the cutting cylinder 1 is matched with the vegetable cutting hole 207.

[0042] Such as Figure 5 , 6As shown, the upper end surface of the fixed table 4 is provided with a lower circular arc groove 402, ...

Embodiment 2

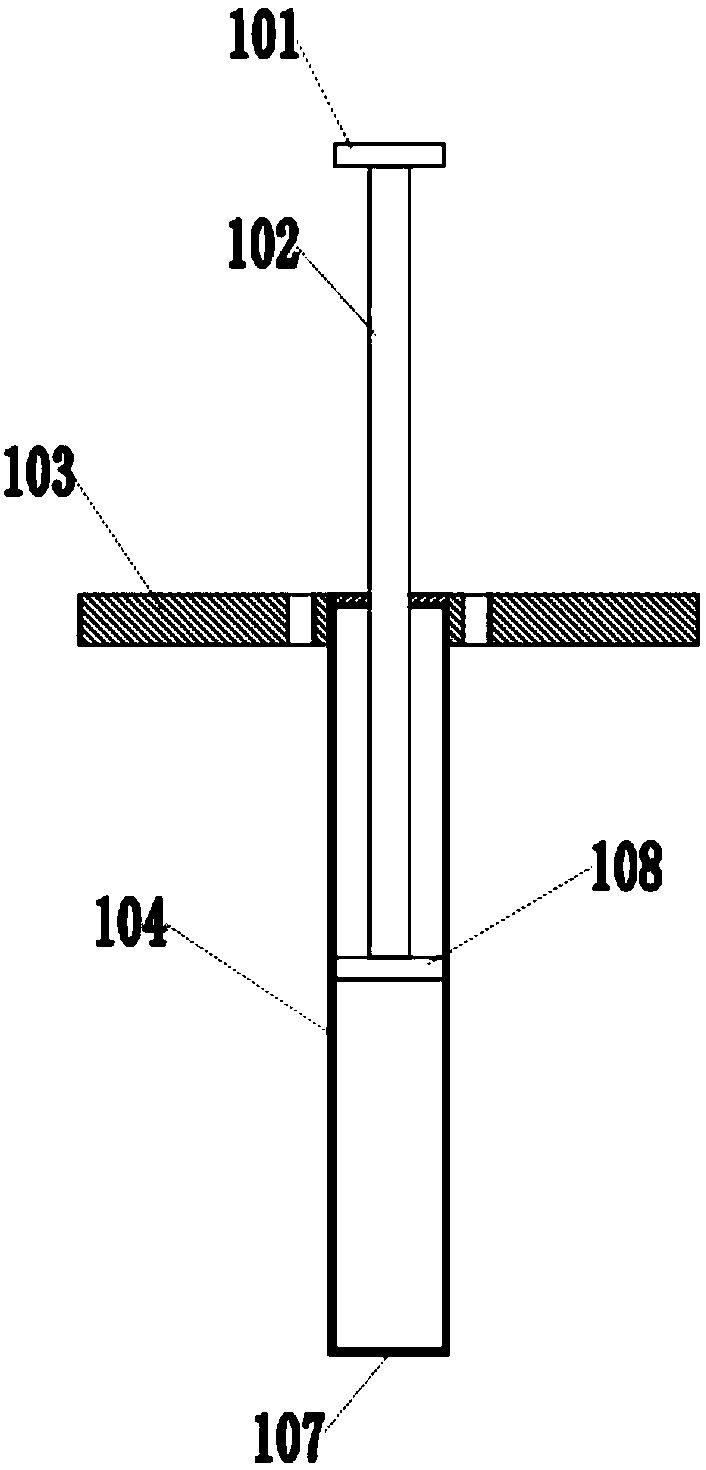

[0049] In order to ensure the convenience when the cutting cylinder 1 cuts downwards and ensure that the cutting cylinder 1 can be accurately inserted into the vegetable outlet hole 405, a guide cylinder 202 and a limit rod 203 are provided.

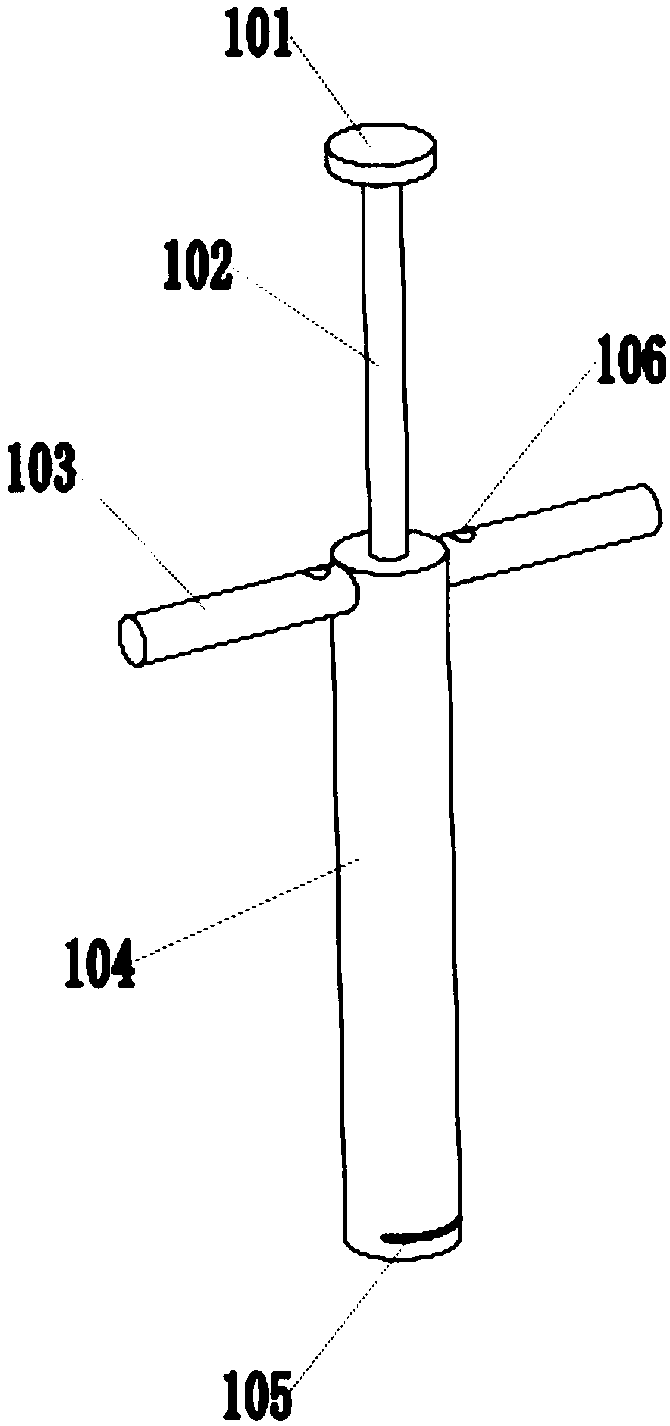

[0050] Such as figure 1 , 4 As shown, the upper end of the pressing plate 2 is provided with a guide cylinder 202 and a limit rod 203, the outer wall of the cylinder body 104 cooperates with the inner wall of the guide cylinder 202, and the pressing handle 103 is provided with a first slide hole 106 , the first sliding hole 106 cooperates with the limiting rod 203 , and the upper end of the limiting rod 203 is provided with a limiting block 204 .

[0051] When cutting and sampling, it is only necessary to press down along the limit rod 203 to cut, and the cutting is more convenient. The cooperation between the cutting cylinder 1 and the vegetable outlet hole 405 is more accurate, and the use is more convenient and safe.

Embodiment 3

[0053] In order to increase the convenience of topping dishes, a lock plate 6 is set to fix the cutting cylinder 1 .

[0054] Such as Figure 6-9 As shown, the side wall of the fixed table 4 is provided with a lock hole 403 communicating with the vegetable hole 405, the lock plate 6 is arranged in the lock hole 403, and the lock plate 6 is arranged at one end of the fixed table 4 inside. The matching groove 601, the upper end of the matching groove 601 is arranged obliquely, which is convenient to cooperate with the cylinder body 104, the lower outer side wall of the cylinder body 104 is provided with a fixing groove 105, and the fixing groove 105 is matched with the locking plate 6, The other end of the lock plate 6 is provided with an opening handle 604 , and a limiting plate 602 is provided near the opening handle 604 , and the limiting plate 602 is connected to the outer side wall of the fixed platform 4 through a limiting pin 7 .

[0055] The limit plate 602 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com