A short-circuit test method for a medium-voltage busbar of an EMU

A technology of bus short circuit and test method, which is applied in the direction of short circuit test, measuring electricity, measuring device, etc., can solve the problems of expanding the short circuit influence area, medium voltage bus loss, poor usability, etc., to reduce the fault influence range and refine the short circuit Point of failure, effect of avoiding failure effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

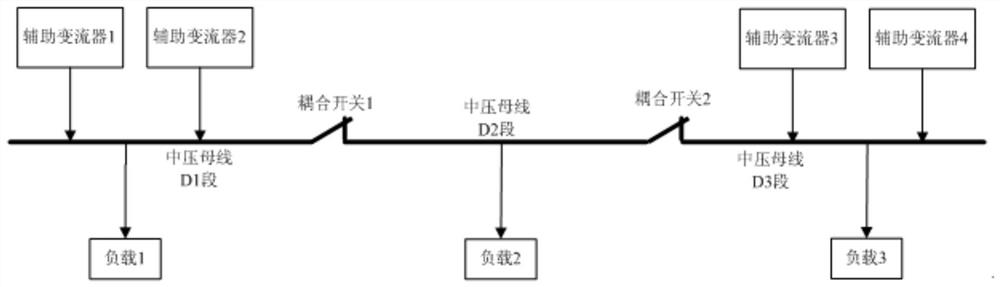

[0020] refer to figure 1 , set 2 coupling switches on the medium voltage bus, divide the medium voltage bus into 3 sections, auxiliary converters 1 and 2 are located in section D1, auxiliary converters 3 and 4 are located in section D3, no auxiliary converter works on section D2 .

[0021] Under normal circumstances, both coupling switches 1 and 2 are closed, and 4 auxiliary converters supply power to the entire medium voltage busbar. When section D1 is short-circuited, open coupling switch 1 to operate; when section D3 is short-circuited, open coupling switch 2 to operate; when section D2 of the medium-voltage bus is short-circuited, open coupling switches 1 and 2 to operate.

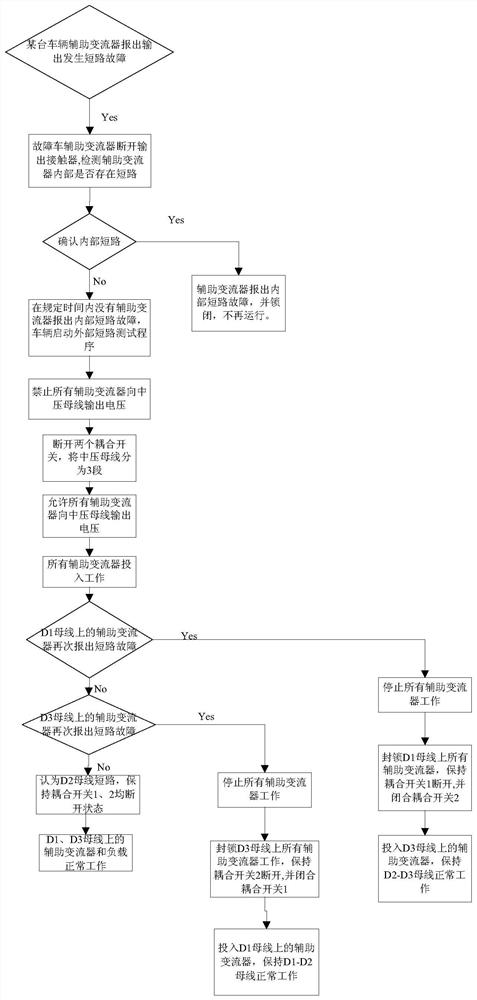

[0022] refer to figure 2 , when the train is running normally, the coupling switches 1 and 2 are closed to run. If a short circuit occurs, the test procedure is as follows:

[0023] 1) During the operation of the train, if a short circuit is found in the auxiliary converter of a certain vehicle, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com