steel ladle management device based on an RFID technology

A management device, RFID tag technology, applied in the direction of collaborative operation devices, electromagnetic radiation induction, instruments, etc., can solve the problems that ordinary RFID tags cannot work, reduce the reading distance of tags, and increase the temperature in the package, so as to improve production safety. , the effect of reducing heat and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be noted that those skilled in the art can make several changes and improvements without departing from the concept of the present invention. These all belong to the protection scope of the present invention.

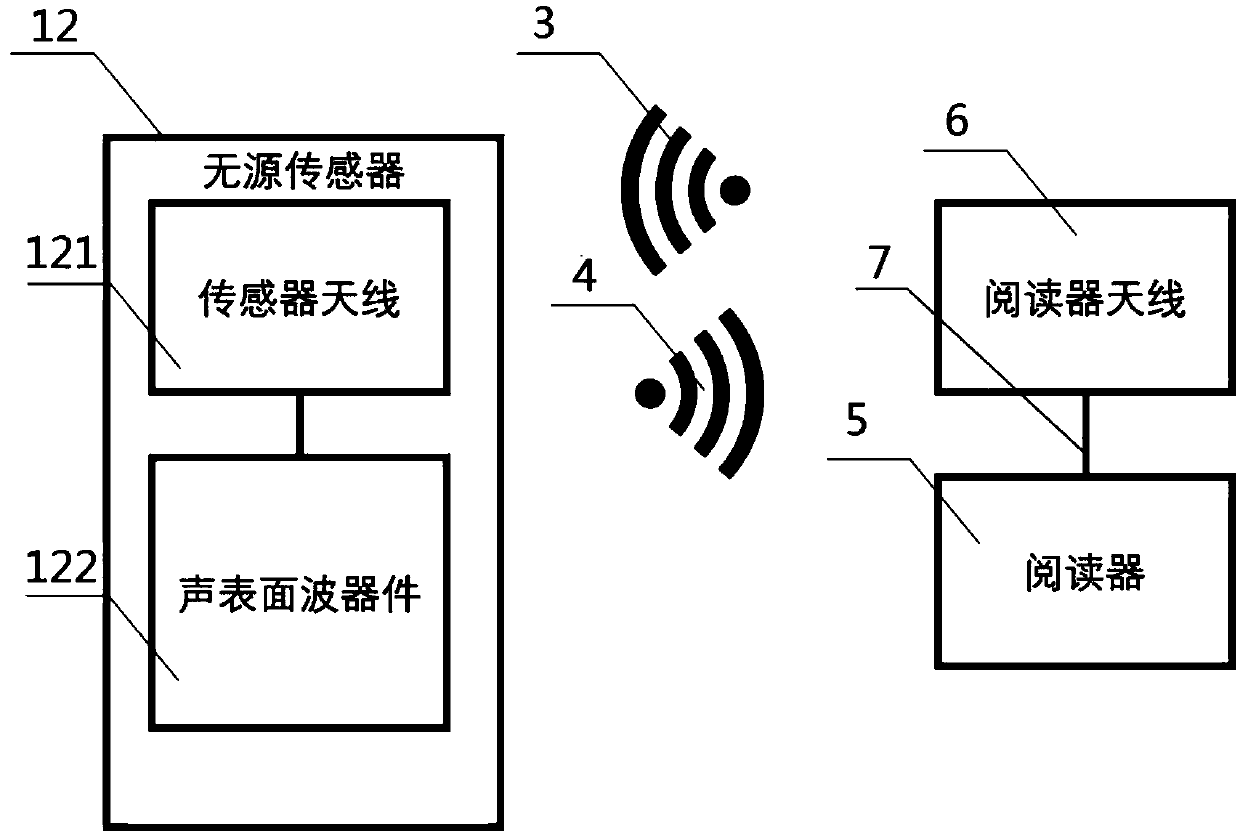

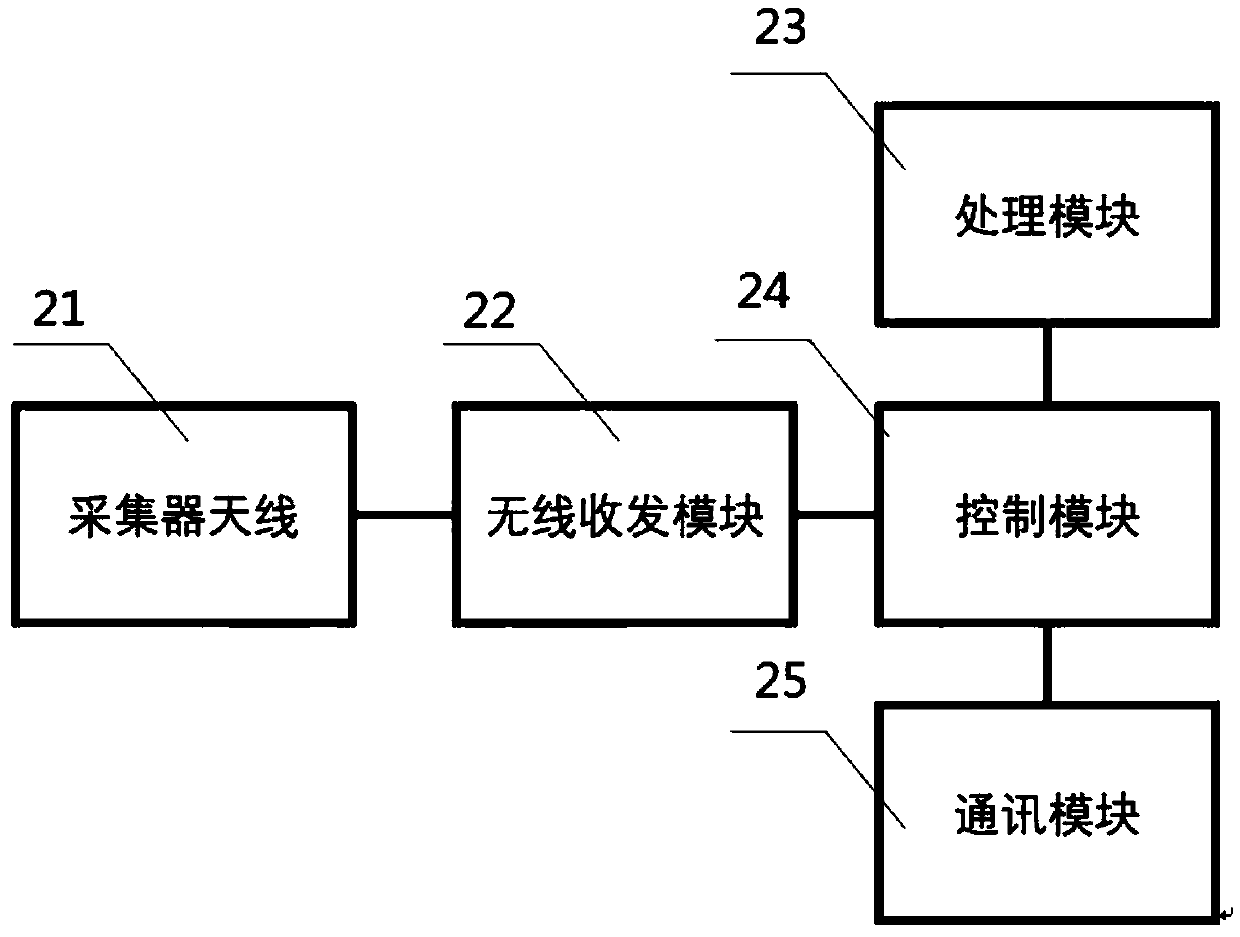

[0044] According to a kind of ladle management device based on RFID technology provided by the present invention, it comprises a UHF RFID tag 1 and a wireless collector 2;

[0045] The UHF RFID tag 1 is arranged on the surface of the steel ladle, and the wireless collector 2 communicates with the UHF RFID tag 1 in a wireless or wired manner to obtain the steel ladle information in the UHF RFID tag 1;

[0046] The wireless collector 2 supports remote monitoring, and uses the received ladle information fo...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap