Micro device transfer apparatus, transfer system and transfer method

A micro-device transfer, micro-device technology, applied in semiconductor/solid-state device manufacturing, electrical components, conveyor objects, etc., can solve the problems of high error rate, low transfer efficiency of micro devices, etc., to achieve high transfer efficiency, low cost, Good transfer accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

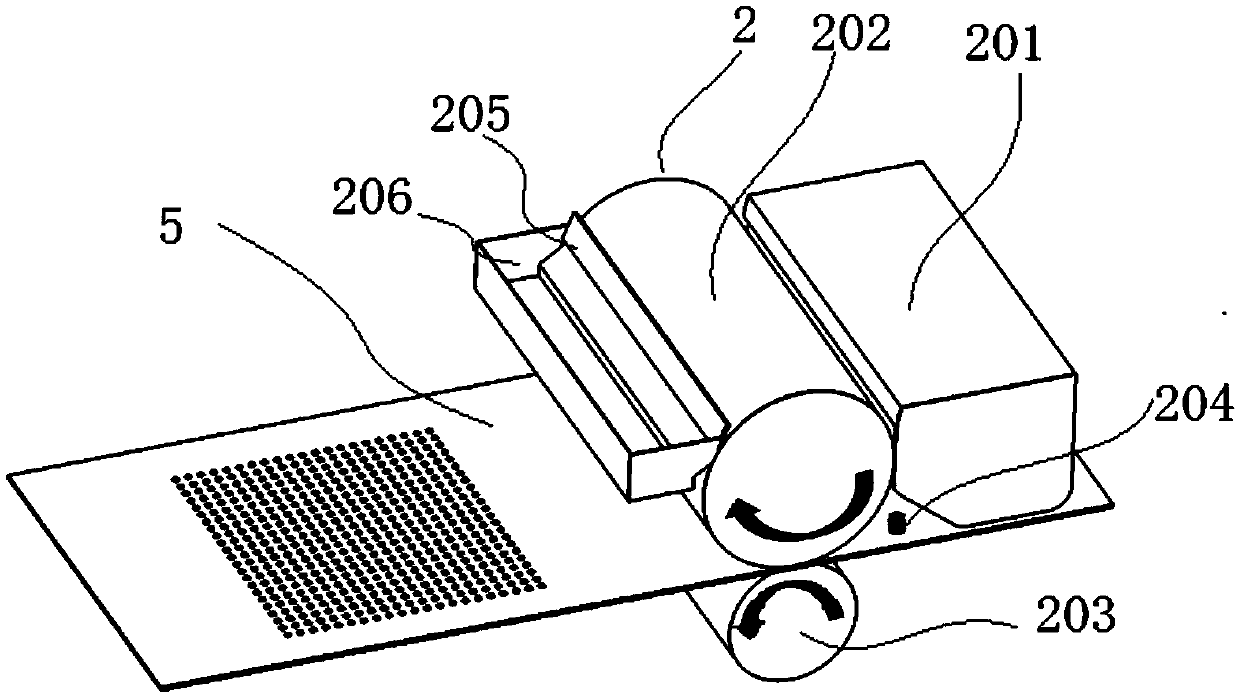

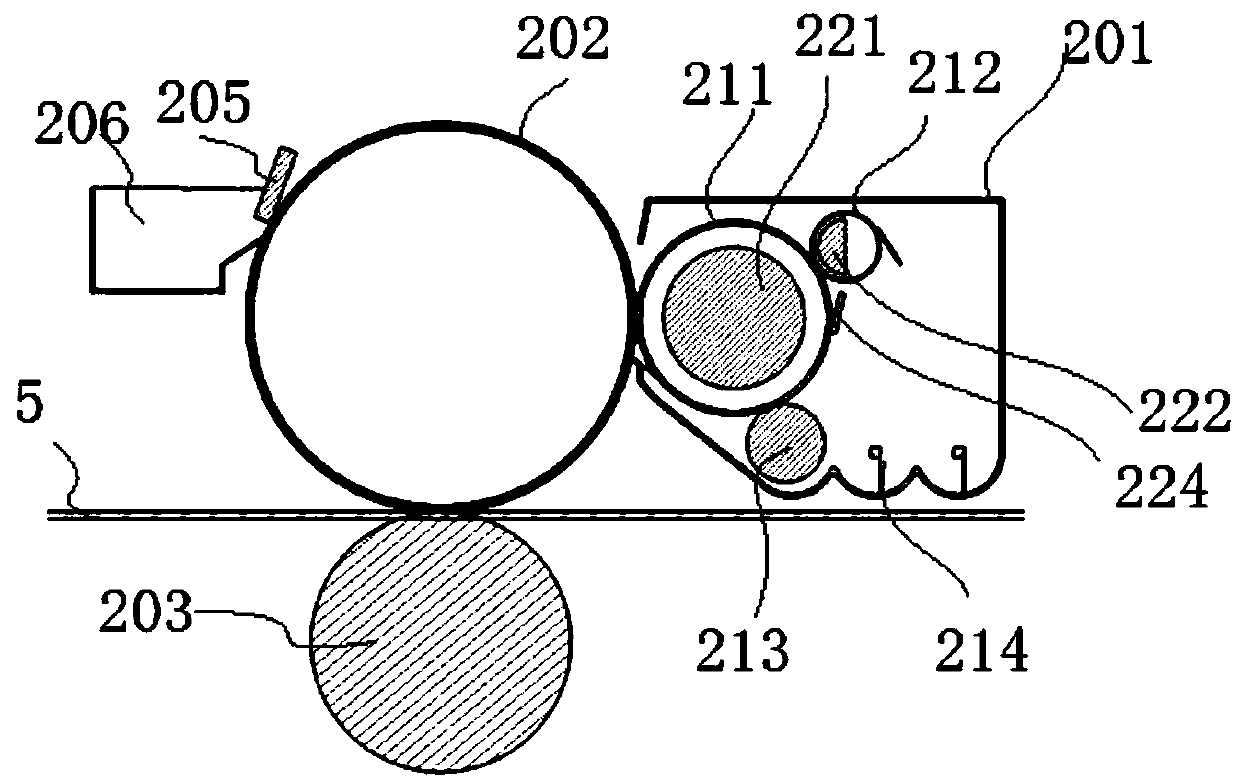

[0065] In order to solve the above problems, this program provides a transfer device for micro-devices designed using electric field transfer technology, such as figure 1 , 2 As shown, the micro-device transfer device includes a micro-device transfer box 201, a cleaning mechanism, and a switching mechanism. The micro-device 1 is set in the micro-device transfer box 201, and the inside bottom of the micro-device transfer box 201 is provided with a stirring device, which is a stirring rod 214 in this embodiment, but other forms of stirring devices can also be used.

[0066] The micro-device transfer box 201 transfers the micro-device 1 from the micro-device transfer box 201 to the induction device 202 of the conversion mechanism; the electric field induction transfer technology is used to transfer the micro-device 1; the induction device is a metal roller or an external connection through a belt A plurality of roller structures, metal rollers or belts are provided with a conduc...

Embodiment 2

[0082] Embodiment 2 is basically the same as Embodiment 1, except that the sensing device 202 corresponds to multiple micro-device transfer cassettes 201 at the same time, and the micro-device transfer cassettes 201 here may contain single-color or multi-color micro-device.

Embodiment 3

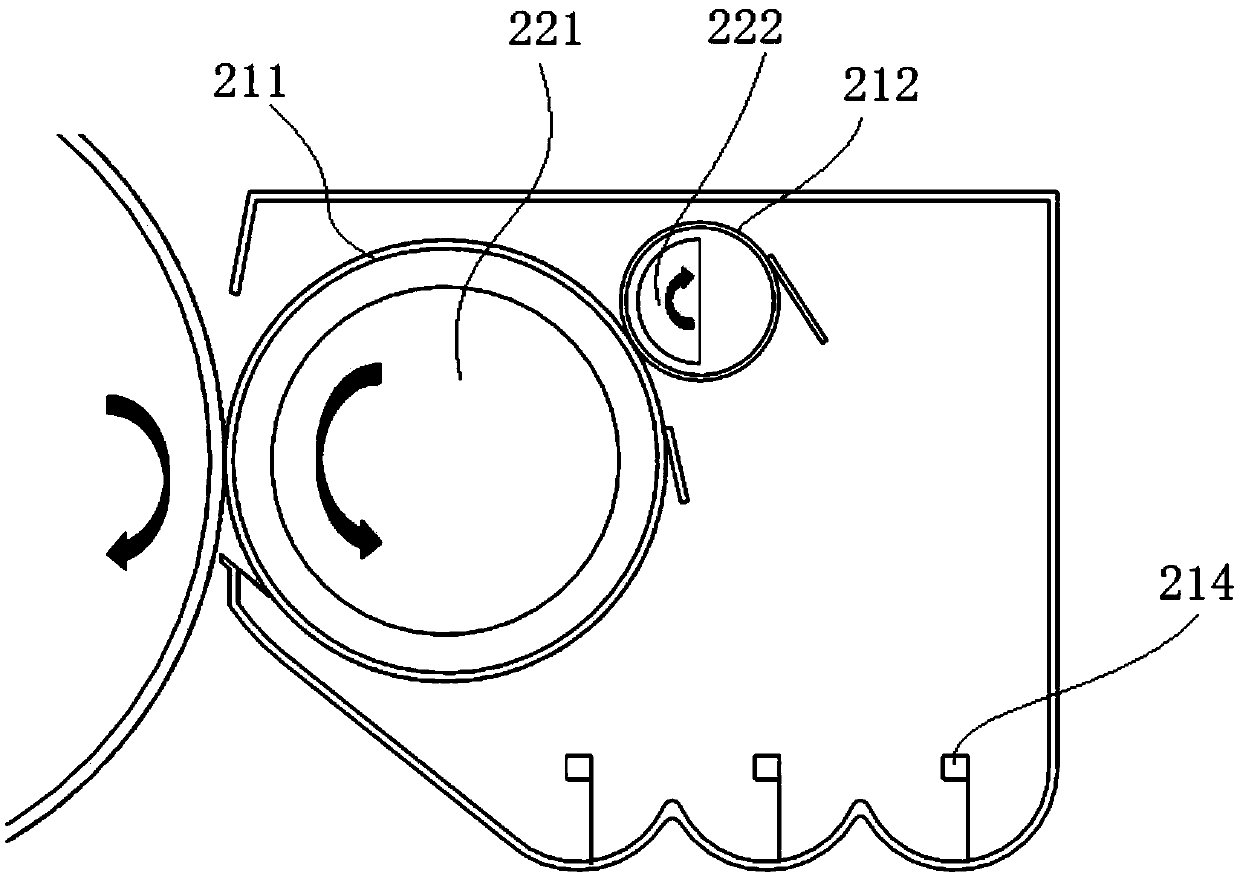

[0084] Embodiment 3 is basically the same as Embodiment 1 or 2, and also includes a supply wheel 213. The supply wheel 213 is arranged under the interior of the micro device transfer box 201, and is in close contact with the lower part of the transfer roller 211. The micro device 1 is pushed to the supply by stirring. Wheel 213, the supply wheel 213 pushes the micro device 1 to the transfer roller 211, the micro device 1 is placed in the box, and pushed to the transfer roller 211 after being stirred, the supply wheel 213 rubs against the transfer roller 211 so that the micro device 1 is adsorbed on the hole of the transfer roller 211 In the process, the micro-device 1 is scraped off the superfluous micro-device 1 adsorbed on the surface of the transfer roller 211 via a scraper, and the micro-light-emitting diode 1 is also pushed into the hole on the surface of the transfer roller 21, and the micro-device 1 is processed according to the hole on the surface of the transfer roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com