Main circuit topology based on igbt parallel current sharing

A technology of topology structure and main circuit, applied in the direction of conversion equipment structural parts, output power conversion device, conversion of AC power input to DC power output, etc., can solve problems such as restricting parallel connection of IGBTs and no longer focusing on static current sharing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

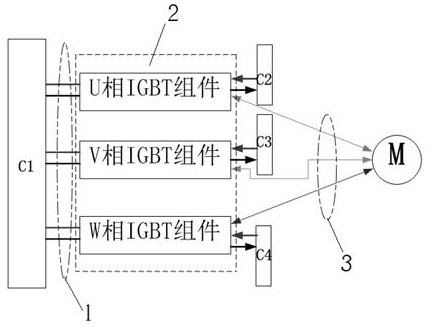

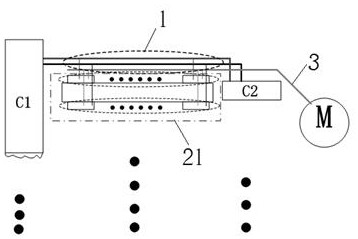

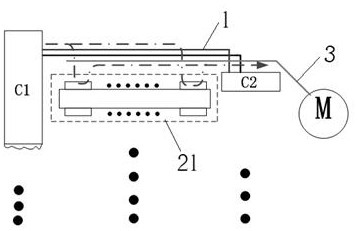

[0016] Example figure 1 As shown, the main circuit topology based on IGBT parallel current sharing in the present invention includes a high-power main film capacitor module C1, a DC bus bar 1, a three-phase IGBT parallel half-bridge assembly 2, and a three-phase output copper bar 3. The high-power main The film capacitor module C1 is connected to the DC busbar 1, the input end of the three-phase IGBT parallel half-bridge assembly 2 is connected to the DC busbar 1, the output end is connected to the three-phase output copper bar 3, and the three-phase output copper bar Row 3 is connected to the three-phase terminals of the motor M. This topology structure also includes three auxiliary film capacitors C2, C3, and C4. The DC busbar 1 is stacked, and the three auxiliary film capacitors C2, C3, and C4 are arranged The output side of the three-phase IGBT parallel half-bridge assembly 2 is connected to the DC busbar 1 respectively, and the three-phase IGBT parallel half-bridge assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com