SiC MOSFET sub-module unit and crimping type package thereof

A crimp-type, sub-mold technology, applied in electrical components, semiconductor/solid-state device parts, semiconductor devices, etc., can solve the problem that silicon carbide devices are difficult to be crimped and packaged.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Embodiments of the present invention are described in further detail below:

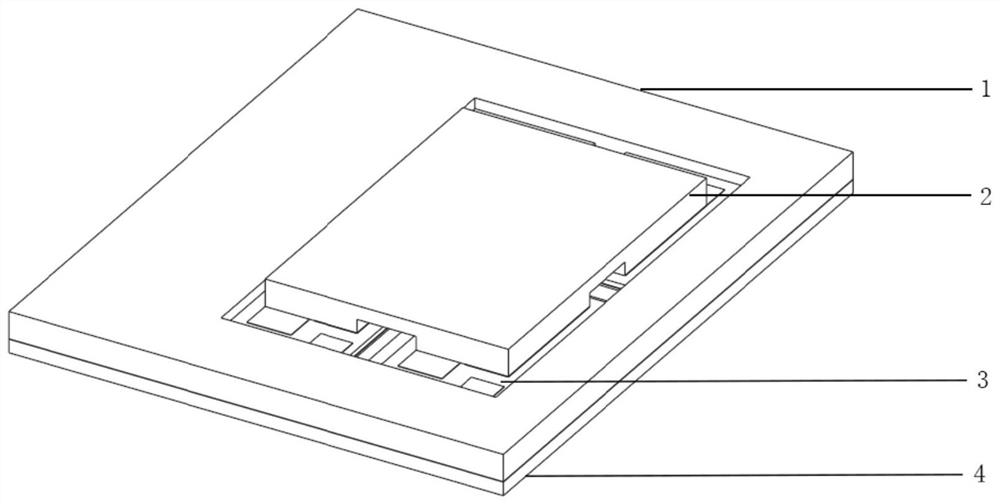

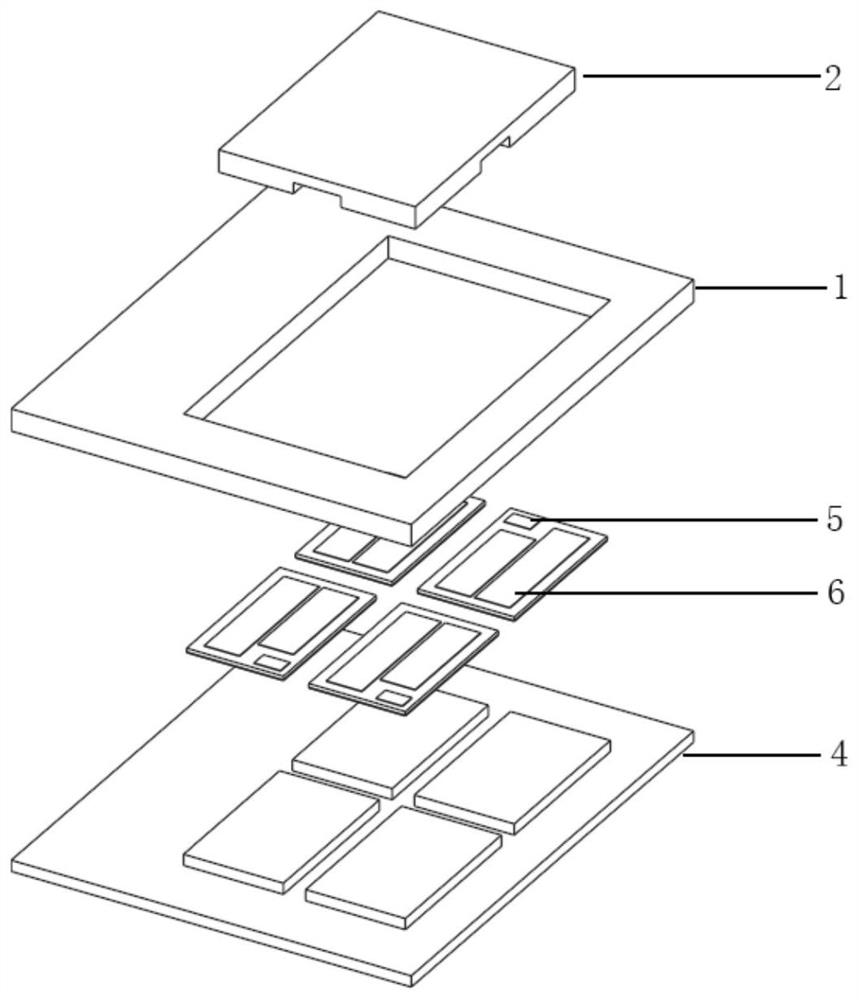

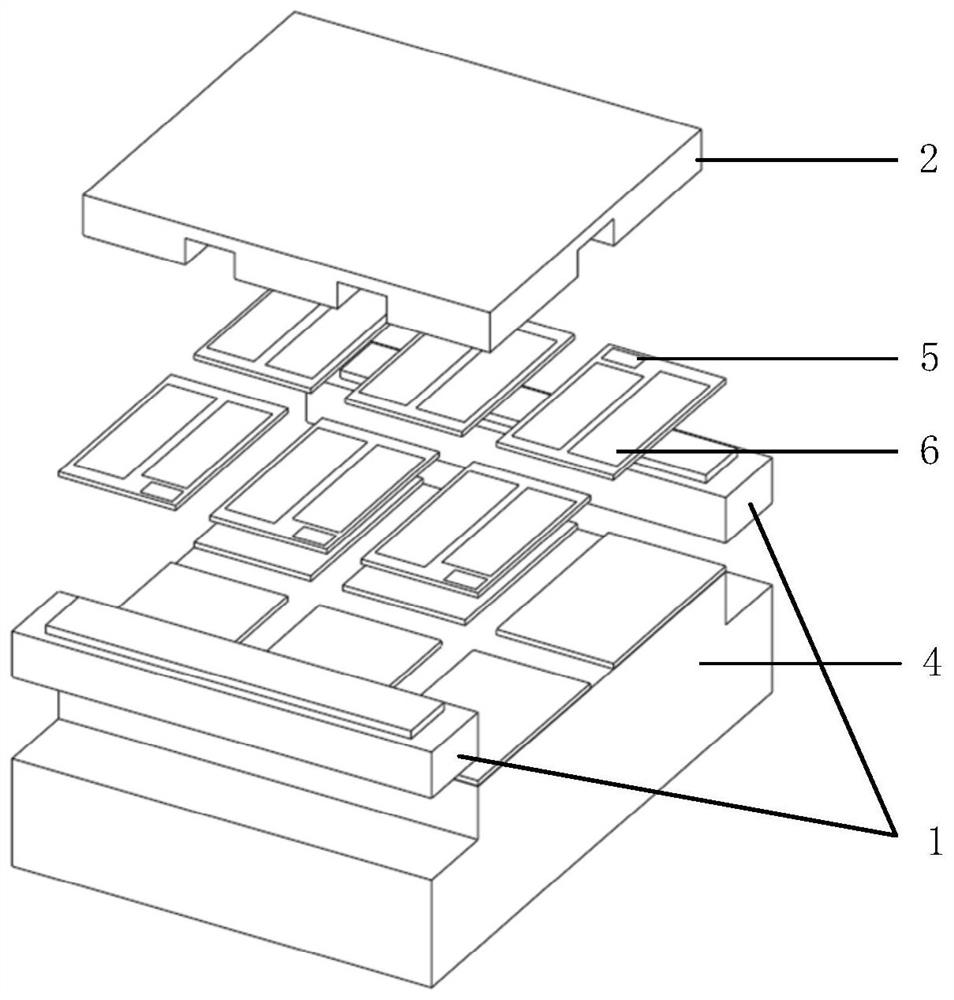

[0041] The SiCMOSFET sub-module unit designed in the present invention includes a source molybdenum sheet 2 , a SiCMOSFET chip array 3 , a DBC ceramic substrate 1 and a drain molybdenum sheet 4 . The lower surface of the source molybdenum sheet 2 is cut into four raised areas, and each raised area is respectively connected to the source 6 of the SiCMOSFET chip array 3 through nano-silver sintering, and does not cover the gate and terminal ; The SiCMOSFET chip array 3, each sub-module contains four pieces, one side of the source 6 faces upwards, and the grid 5 faces the outside, and is connected to the DBC ceramic substrate 1 on its periphery through bonding wires; the drain Pole molybdenum sheet 4, one side of which is connected to the drain of the SiCMOSFET chip array 3 through nano-silver sintering; The edge is a smooth arc; the internal gap of the SiCMOSFET sub-module unit 9 is filled with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com