Electrothermal film assembly and manufacturing method thereof

A technology of thin film components and manufacturing methods, which is applied in the direction of ohmic resistance heating parts, electrical components, electric heating devices, etc., can solve the problems of low heat radiation efficiency and heat extraction efficiency, large power loss, low safety, etc., and achieve electric heating function Stable, reduce the loss of electric energy, high security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

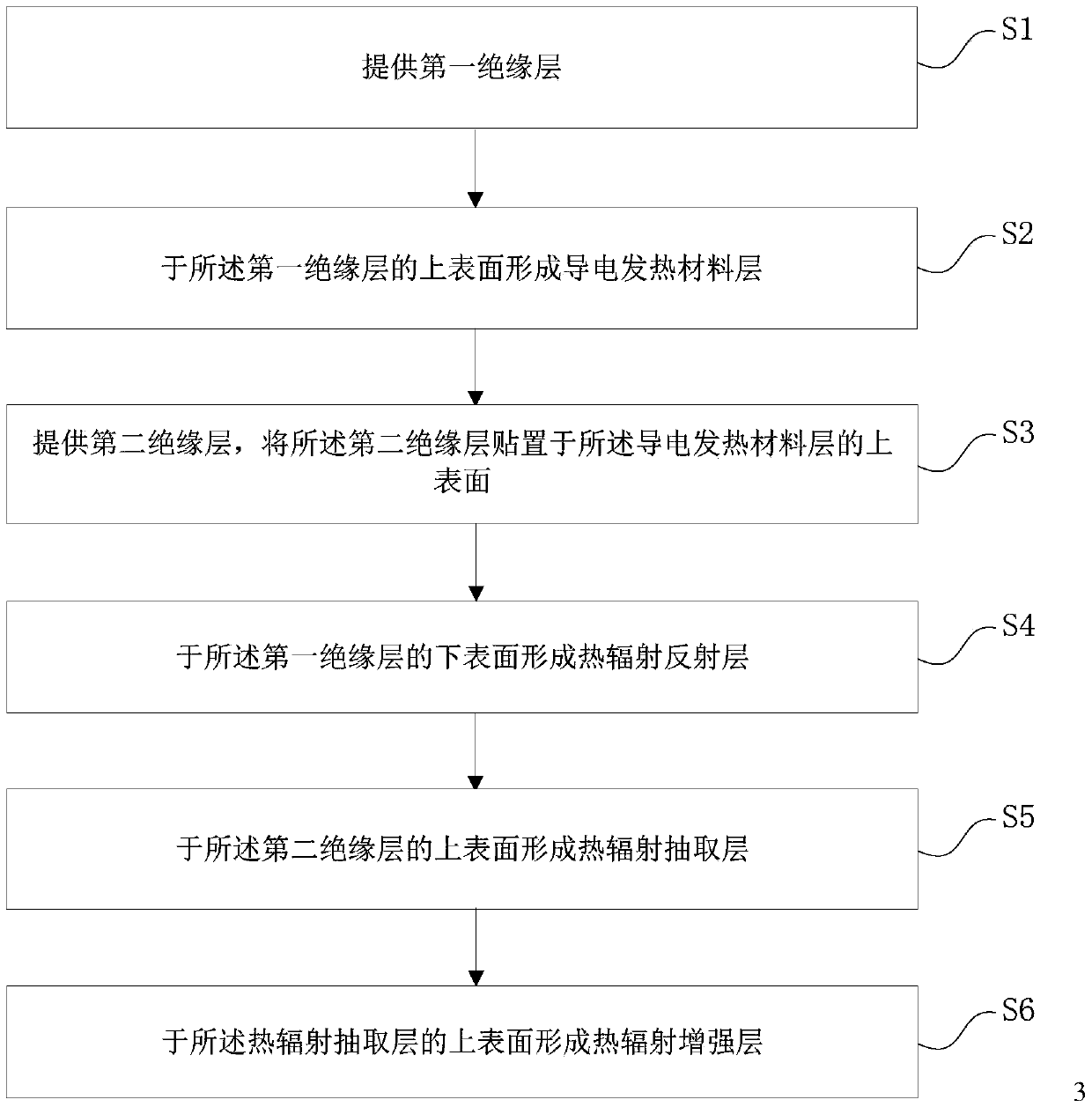

[0060] Please figure 1, the present embodiment provides a method for manufacturing an electrothermal film assembly, the method for manufacturing an electrothermal film assembly includes the steps of:

[0061] 1) providing a first insulating layer;

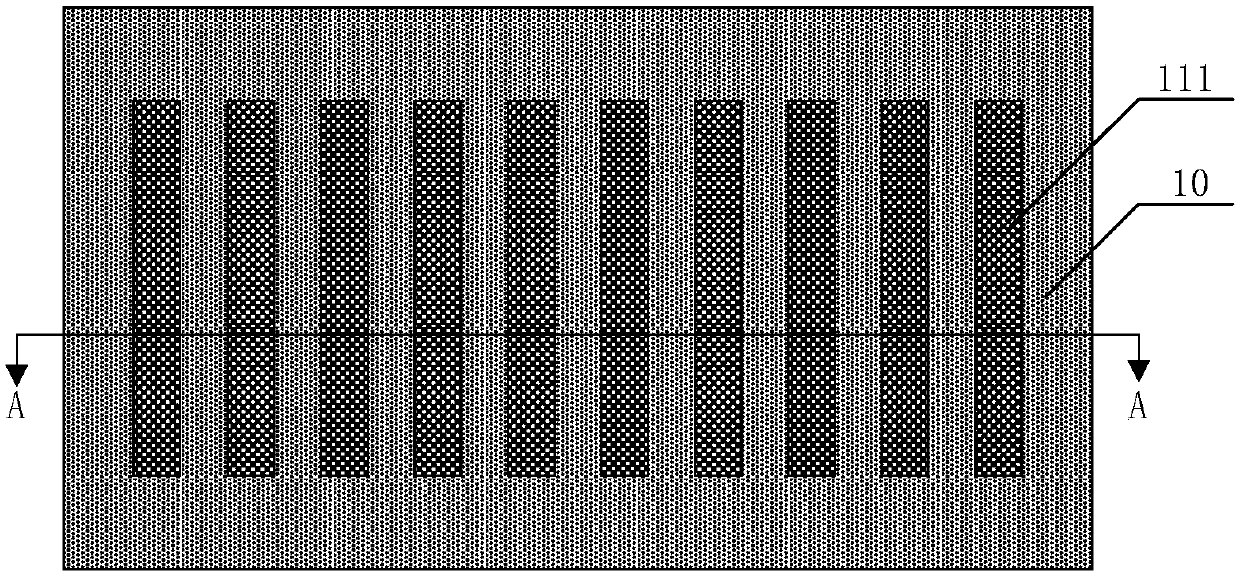

[0062] 2) forming a conductive heating material layer on the upper surface of the first insulating layer;

[0063] 3) providing a second insulating layer, and affixing the second insulating layer on the upper surface of the conductive heating material layer;

[0064] 4) forming a heat radiation reflective layer on the lower surface of the first insulating layer;

[0065] 5) forming a heat radiation extraction layer on the upper surface of the second insulating layer;

[0066] 6) Forming a thermal radiation enhancing layer on the upper surface of the thermal radiation extraction layer.

[0067] In step 1), see figure 1 In the S1 step, the first insulating layer 10 is provided.

[0068] As an example, the first insulating layer...

Embodiment 2

[0111] Please combine Figure 2 to Figure 9 read on Figure 10 to Figure 12 , this embodiment also provides an electrothermal film assembly, the electrothermal film assembly includes: a first insulating layer 10; a conductive heating material layer 11, the conductive heating material layer 11 is located on the upper surface of the first insulating layer 10; The second insulating layer 12, the second insulating layer 12 covers at least the upper surface of the conductive heating material layer 11; the heat radiation reflecting layer 13, the heat radiation reflecting layer 13 is located under the first insulating layer 10 Surface; thermal radiation extraction layer 14, the thermal radiation extraction layer 14 is located on the upper surface of the second insulating layer 12; thermal radiation enhancement layer 15, the thermal radiation enhancement layer 15 is located on the thermal radiation extraction layer 14 surface.

[0112] As an example, the first insulating layer 10 ma...

Embodiment 3

[0137] Please combine Figure 2 to Figure 9 read on Figure 10 to Figure 12 , this embodiment also provides an electric heating device, the electric heating device includes the electrothermal film assembly as described in Embodiment 2, the heat radiation reflective layer 13 and the heat radiation extraction in the electrothermal film assembly Layer 14 is connected to the ground wire of the power supply. For the specific structure of the electrothermal film assembly, please refer to Embodiment 2, which will not be repeated here.

[0138] As an example, the electric heating device may include, but not limited to, electric blankets, floor heaters, electric seat cushions, electric floor mats, electric ceilings, electric walls, and the like.

[0139] As mentioned above, the electrothermal film assembly and its manufacturing method of the present invention, the electrothermal film assembly includes: a first insulating layer; a conductive heating material layer located on the upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com