Orleans chicken powder and its preparation method

A technology of Orleans chicken and chicken powder, which is applied in food science, food preservation, food drying, etc., can solve the problems that chicken powder cannot be widely used, and achieve the effect of solving the loss of flavor, full of flavor and full taste of the material

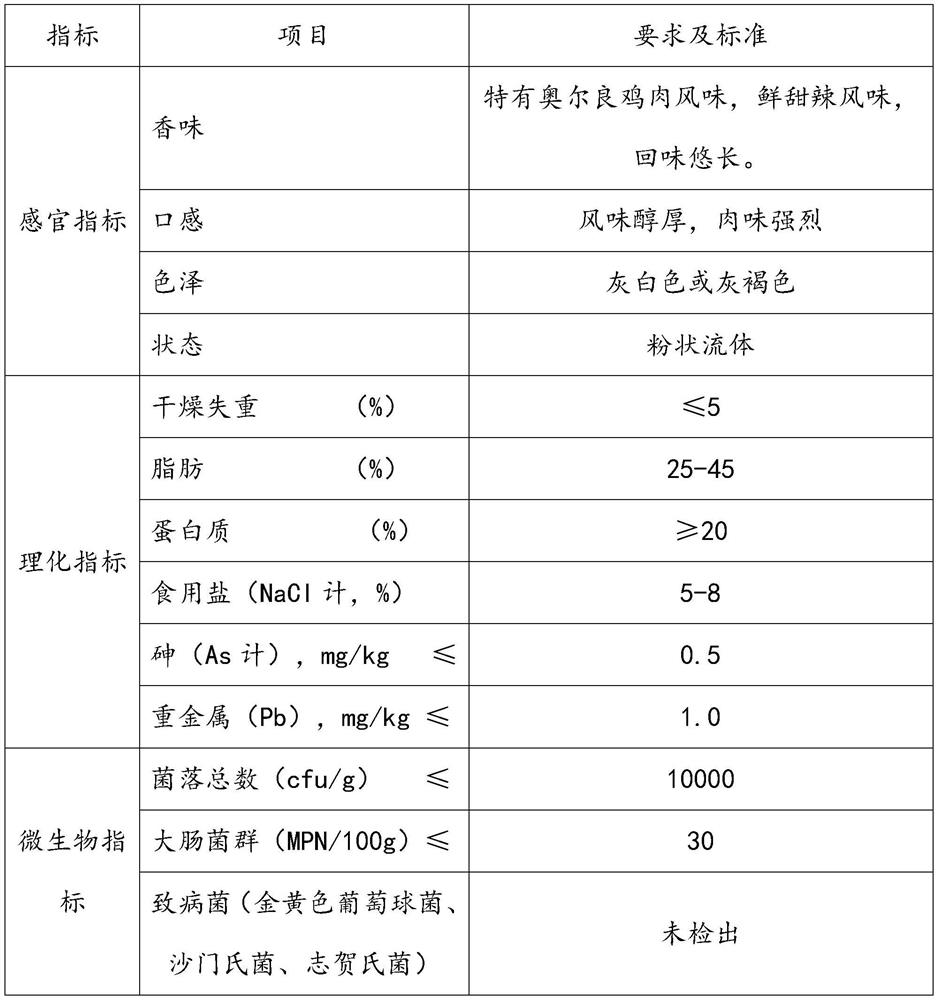

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In addition, the present invention also provides a kind of preparation method of above-mentioned Orleans chicken powder, and this preparation method comprises the following steps:

[0035] (1) Raw material processing: Use the whole meat chicken or the chicken skeleton with the head and claws removed as the raw material. After cleaning and removing the blood, put it into a special extraction cage;

[0036] (2) Precooking: add water to the high-temperature cooking tank, and heat up to 95°C, put the raw materials treated in step (1) into the high-temperature cooking tank through the extraction cage, keep for 10 minutes, and drain the water , re-add 10% of the raw material weight of water, and add 1% of the raw material weight of cooking wine, heat up to 98-100 ° C, and keep the temperature of 98-100 ° C for 30 minutes in the state of opening the cover;

[0037] (3) Flavoring reaction: after precooking, add the first material, the first material includes white sugar, xylose...

Embodiment 1

[0047] The preparation method of Orleans chicken powder in the present embodiment is:

[0048] (1) Raw material treatment: Use whole chicken with head and claws removed or chicken with broiler skeleton as raw material. The raw material is produced by a manufacturer that has obtained a food production license. After inspection, it meets the requirements of GB2707. After cleaning the raw material and removing blood , put into special-purpose extraction cage, every cage 2000kg, and chicken kind is white-feathered broiler among the present embodiment;

[0049] (2) Precooking: Add 3000L of water into the high-temperature cooking tank, and heat up to 95°C, put the raw material treated in step (1) into the high-temperature cooking tank through the extraction cage, and keep it for 10 minutes. Let it go, re-add 10% of the raw material weight of clear water (200kg), and add 1% of the raw material weight of cooking wine (20kg), heat up to 98-100°C, and keep the temperature of 98-100°C fo...

Embodiment 2

[0059] The preparation method of Orleans chicken powder in the present embodiment is:

[0060] (1) Raw material treatment: Use whole chicken with head and claws removed or chicken with broiler skeleton as raw material. The raw material is produced by a manufacturer that has obtained a food production license. After inspection, it meets the requirements of GB2707. After cleaning the raw material and removing blood , put into special-purpose extraction cage, every cage 2000kg, and chicken kind is white-feathered broiler among the present embodiment;

[0061] (2) Precooking: Add 3000L of water into the high-temperature cooking tank, and heat up to 95°C, put the raw material treated in step (1) into the high-temperature cooking tank through the extraction cage, and keep it for 10 minutes. Let it go, re-add 10% of the raw material weight of clear water (200kg), and add 1% of the raw material weight of cooking wine (20kg), heat up to 98-100°C, and keep the temperature of 98-100°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com