A compound thickening and stabilizing agent for freshly ground nutritional drinks

A technology of thickening stabilizer and nutrition, which is applied in the direction of milk substitutes, dairy products, food preparation, etc., and can solve the problems of no compound thickening stabilizer for freshly ground nutritional drinks, insufficient smoothness of the drink quality, and insufficient fullness of the mouthfeel, etc. , to achieve the effect of good fluidity, long shelf life and full taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

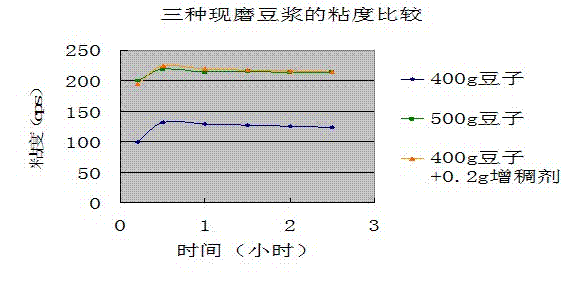

[0013] Example 1 freshly ground soybean milk

[0014] Components of the compound thickening stabilizer: 30% guar gum, 20% xanthan gum, 5% gellan gum, 5% locust bean gum, 20% phosphated cross-linked starch, 20% sucrose-15. Each component is weighed in proportion and placed in a mixing instrument, and mixed for 5 minutes to obtain a compound thickening and stabilizing agent.

[0015] Wash 1 kg of soybeans twice with water to remove impurities, soak them in 4 times their weight of water for 8 hours at room temperature, put them in a pressure cooker, add 2 times their weight of water, and cook them on a gas stove for 10 minutes on high heat. Pour off the remaining water, and after the beans cool down naturally, they can be packed in boxes and placed in the refrigerator for later use. Weigh 500g of cooked soybeans and place them in a smoothie machine, add 1500ml of 80°C hot water, add 2g of compound thickening and stabilizing agent, and grind for 3 minutes. Finally, add 100g of ...

Embodiment 2

[0016] Example 2 freshly ground rice paste

[0017] Components of the compound thickening stabilizer: 40% guar gum, 30% xanthan gum, 5% gellan gum, 5% locust bean gum, 15% phosphated cross-linked starch, 5% polyglycerol ester. Each component is weighed in proportion and placed in a mixing instrument, and mixed for 6 minutes to obtain a compound thickening and stabilizing agent.

[0018] Wash 200g of red rice, 100g of millet, and 100g of barley twice to remove impurities, put them in a pressure cooker, add 1500ml of water, put them on a gas stove and boil on high heat, then turn to low heat and cook for 5 minutes. After the cooked paste cools down naturally, it is packed in boxes and placed in the refrigerator for later use. Weigh 500g of cooked rice paste and place it in a smoothie machine, add 1500ml of 90°C hot water, add 1g of compound thickening and stabilizing agent, and grind at high speed for 1min. Finally, add 150g of sucrose and continue refining for 10s to obtain...

Embodiment 3

[0019] Example 3 Freshly ground mung bean paste

[0020] Components of compound thickening stabilizer: 30% guar gum, 40% xanthan gum, 10% gellan gum, 10% locust bean gum, 5% acetylated distarch ester starch, 5% sucrose ester-11 . Each component is weighed in proportion and placed in a mixing instrument, and mixed for 5 minutes to obtain a compound thickening and stabilizing agent.

[0021] Wash 500g mung beans twice with water to remove impurities, soak them in 3 times the weight of water for 2 hours at room temperature, put them in a pressure cooker, add 4 times the weight of water, and cook them on a gas stove for 8 minutes. After the beans cool down naturally, they can be packed in boxes and placed in the refrigerator for later use. Weigh 600g of cooked mung beans and place them in a high-speed tissue grinder, add 1200ml of 5°C cold water, add 3g of compound thickening and stabilizing agent, and grind for 20s. Finally, add 100g of sucrose and continue refining for 5 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com