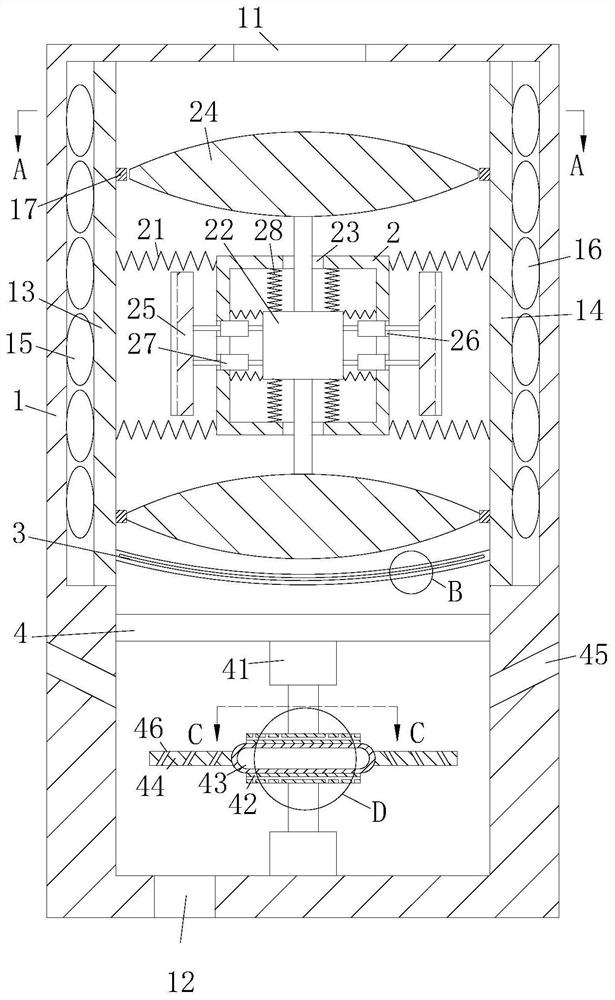

A coal gangue acidification treatment kiln

A technology of acidification treatment and coal gangue, which is applied in grain treatment, chemical/physical process, chemical/physical/physicochemical process, etc. It can solve the problems of lower acidification treatment efficiency, difficult acidification degree of coal gangue, uneven mixing of coal gangue acidification, etc. problem, to achieve the effect of mixing evenly and speeding up the acidification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

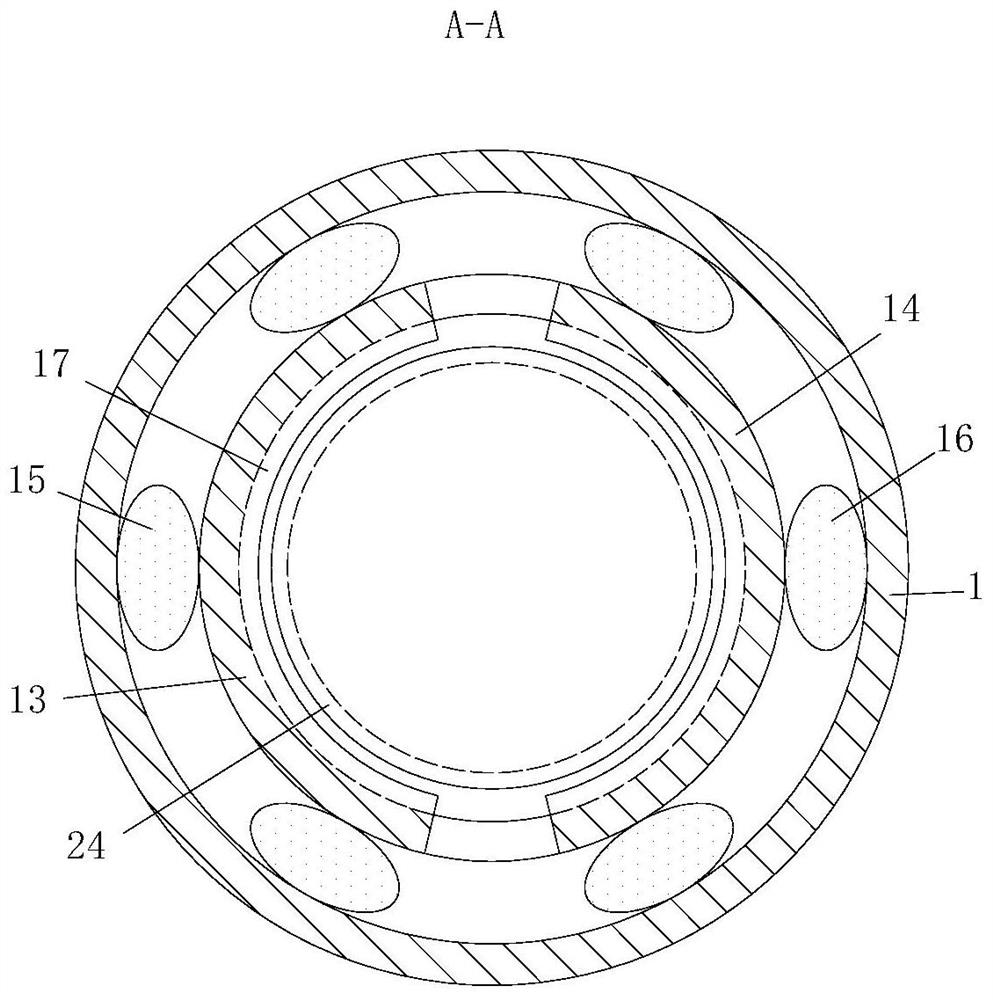

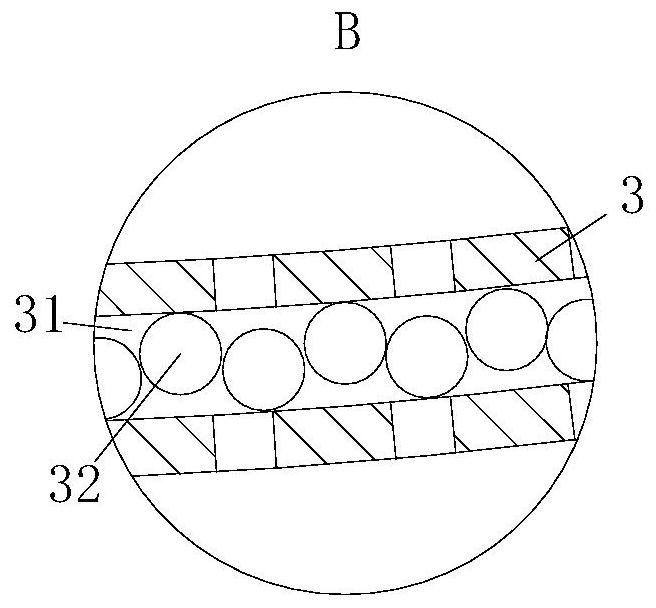

[0025] As an embodiment of the present invention, a filter plate 3 is provided below the drive cabin 2; the filter plate 3 is designed in a circular shape, is fixedly connected to the inner wall of the kiln body 1, and is bent downward; the filter plate 3 adopts Made of polyurethane synthetic rubber, it has the characteristics of strong elasticity, high strength, tear resistance and wear resistance, which effectively ensures the high elasticity of the filter plate 3 and prolongs the service life of the filter plate 3; when working, coal gangue passes through the crushing wheel 24 After being broken, it falls to the surface of the filter plate 3. During the falling process, due to the gravity, the filter plate 3 vibrates. The vibration of the filter plate 3 can strengthen the filtering effect, and at the same time, the gangue can be bounced to play the role of turning over the material. Effectively prevent larger coal gangue from clogging the filter plate 3 and smaller coal gang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com