Automatic punching forming processing equipment for folding pin shaft barrel and application method

A stamping forming and processing equipment technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of hand injury, high risk, injury, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

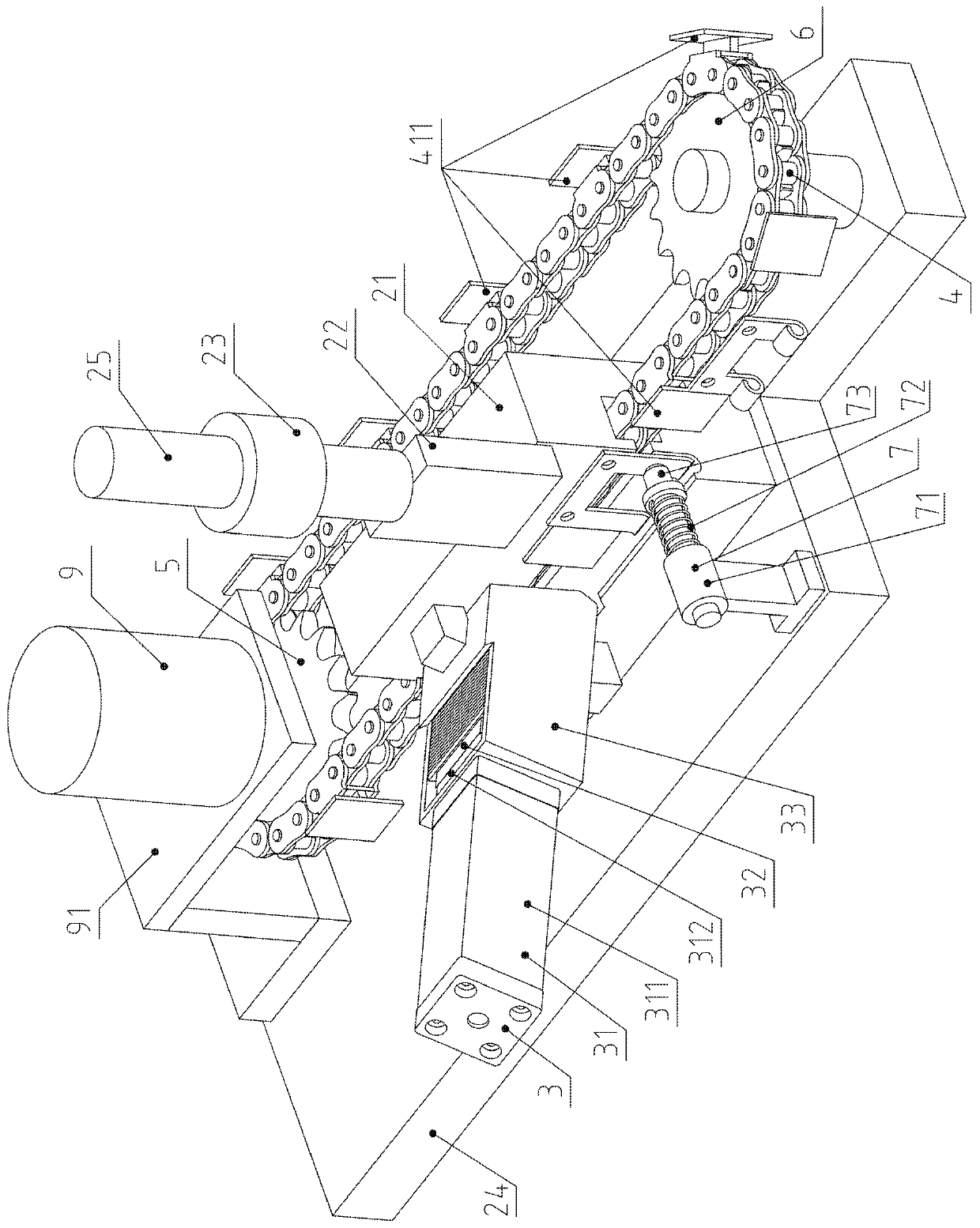

[0048] Example: see Figure 1 to Figure 17 .

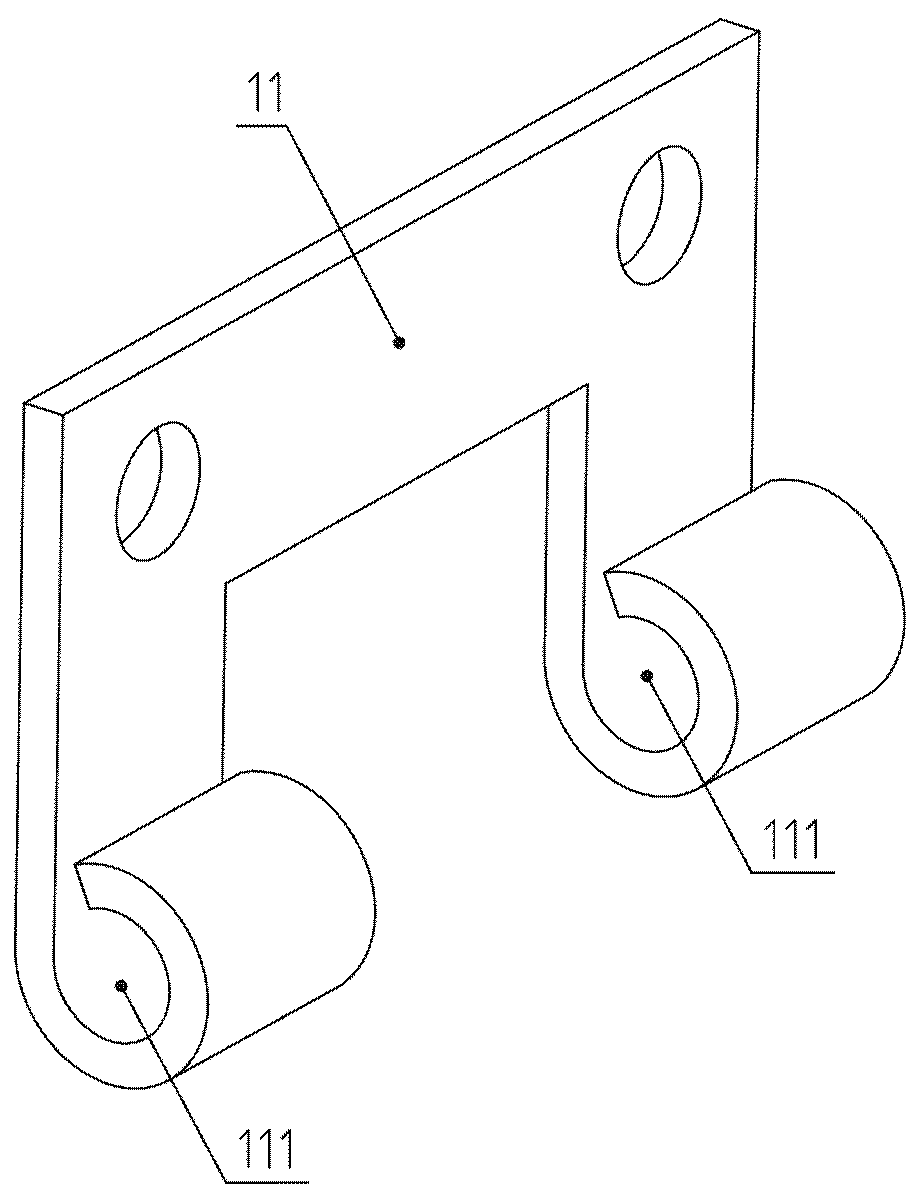

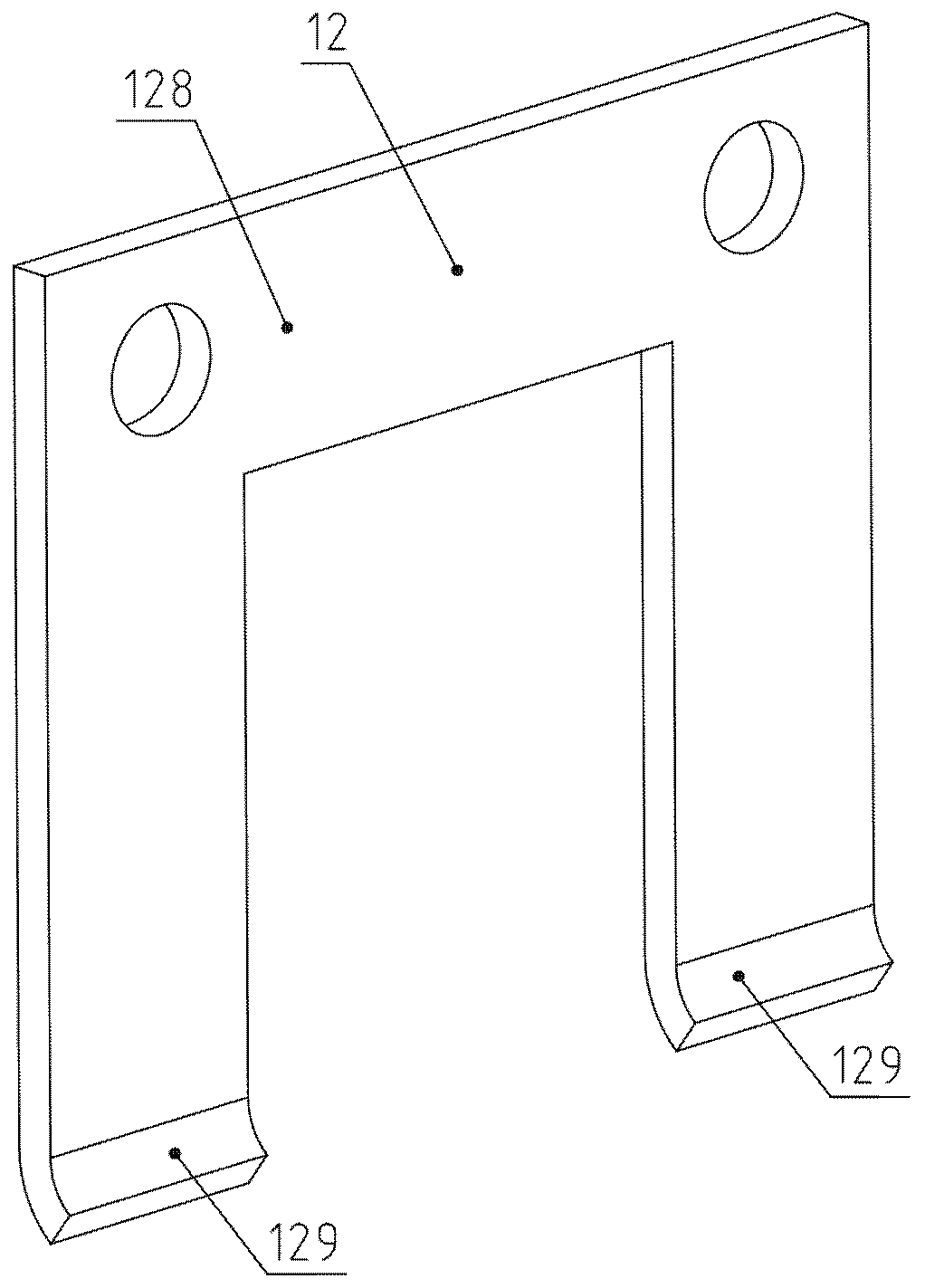

[0049] A processing equipment for automatic stamping and forming of a folding pin cylinder, comprising an upper mold 22 and a lower mold 21; the bottom of the lower mold 21 is fixedly connected to a workbench 24, and the lower mold 21 is provided with a front-facing facade, and The lower part is provided with an arc groove; the upper part of the upper die 22 is fixedly connected with the working shaft handle 25 of the press, and the upper die 22 is plate-shaped;

[0050] It is characterized in that it also includes a material warehouse component 3, a transmission chain 4, a driving sprocket 5, a passive sprocket 6, a pressing component 7, an intermediate pressure relief type three-position five-way solenoid valve 8 and a motor 9;

[0051] The facade of the lower mold 21 is divided into two parts, the left side is the vertical feeding part 211, the right side is the vertical stamping part 213, the arc groove is divided into the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com