Wear-resisting ball cooling discharging device

A technology of a discharge device and a cooling device, which is applied in the field of wear-resistant ball production, and can solve problems such as uneven cooling of steel balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below by means of specific embodiments:

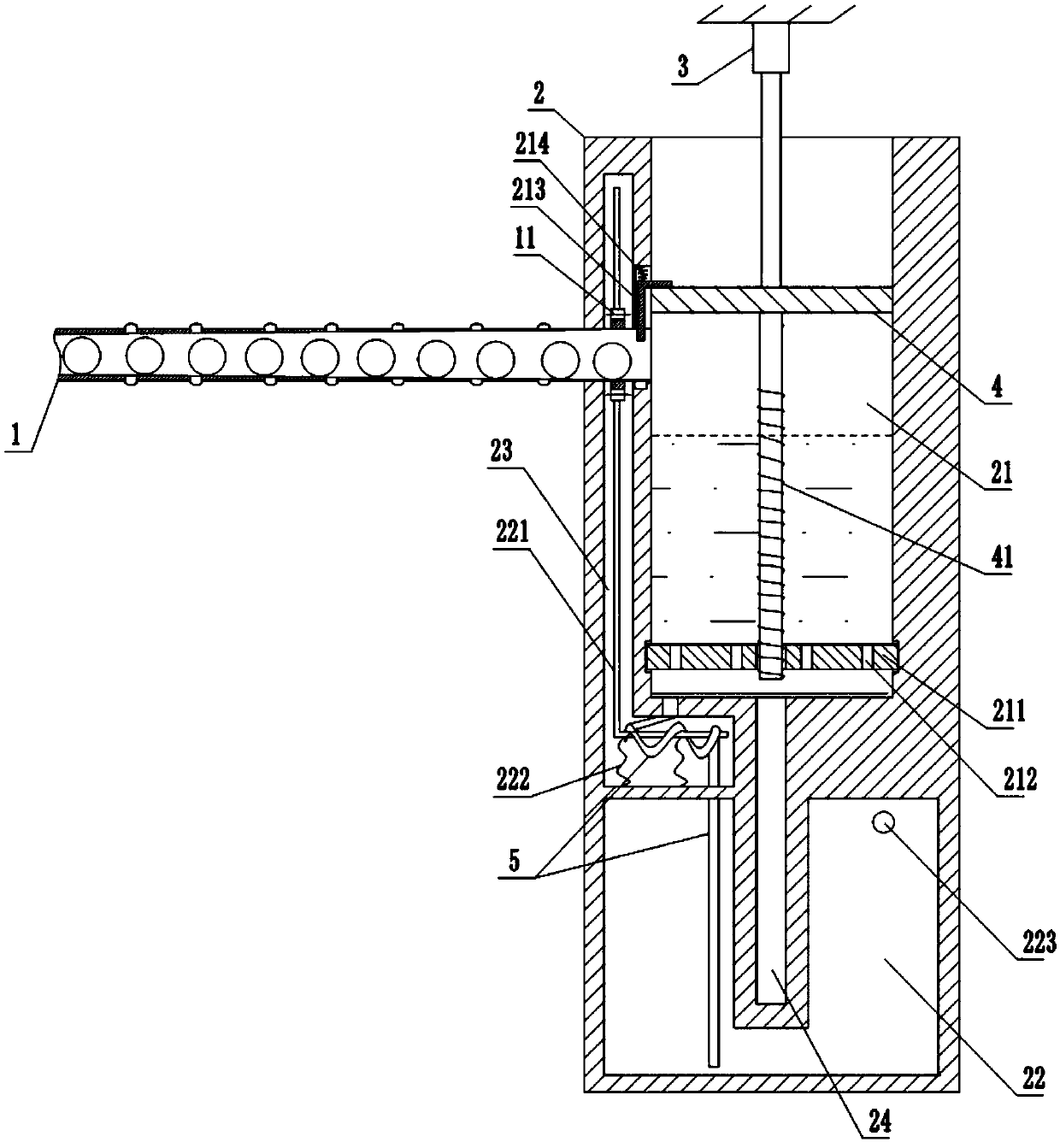

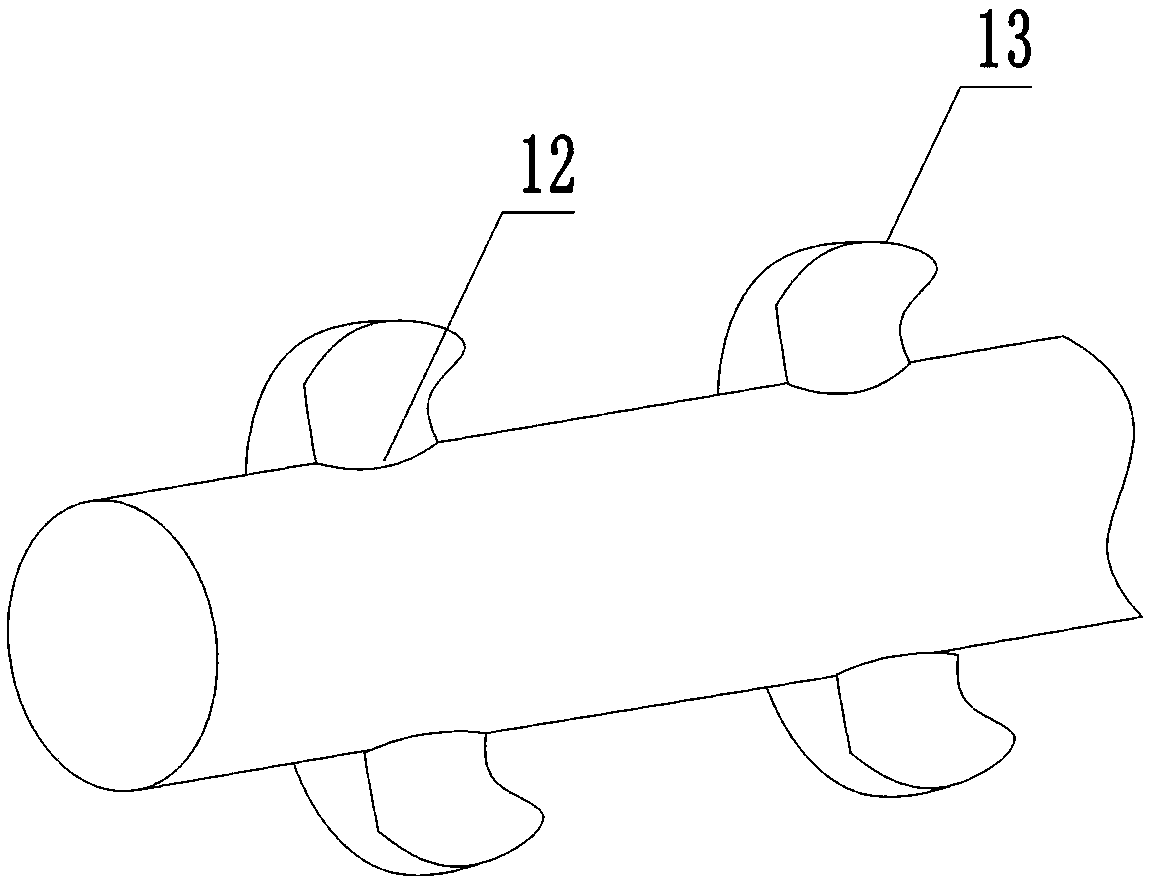

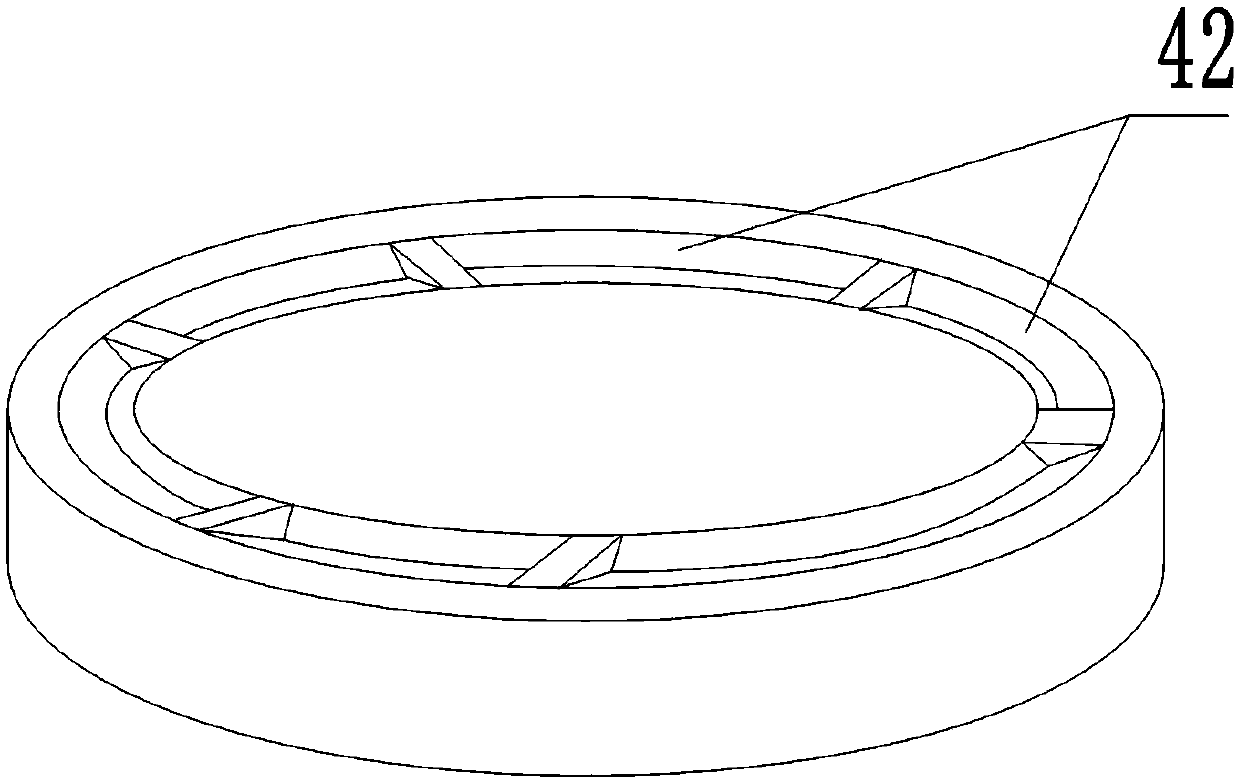

[0028] The reference signs in the accompanying drawings of the specification include: feed pipe 1, ring gear 11, heat dissipation hole 12, air collecting ear 13, cooling device 2, processing chamber 21, rotating disc 211, water leakage hole 212, door panel 213, reset member 214 , Cooling chamber 22, rack 221, elastic member 222, vent hole 223, power chamber 23, stroke channel 24, hydraulic cylinder 3, piston 4, screw rod 41, arc port 42, rubber pad 421, support plate 4211, spring member 4212, water pipe 5.

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 Shown, in order to achieve the above object, basic scheme of the present invention is as follows:

[0030] A wear-resistant ball cooling discharge device, comprising a feed pipe 1 and a cooling device 2, the feed pipe 1 communicates with the upper part of the cooling device 2, and the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com