Method of machining regular holes with laser cutting robot arm

A technology of laser cutting and manipulators, which is applied in manipulators, metal processing equipment, laser welding equipment, etc., can solve the problems of many graphics, cumbersome teaching, and poor trajectory running accuracy, so as to improve the accuracy of laser cutting and simplify the teaching process , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

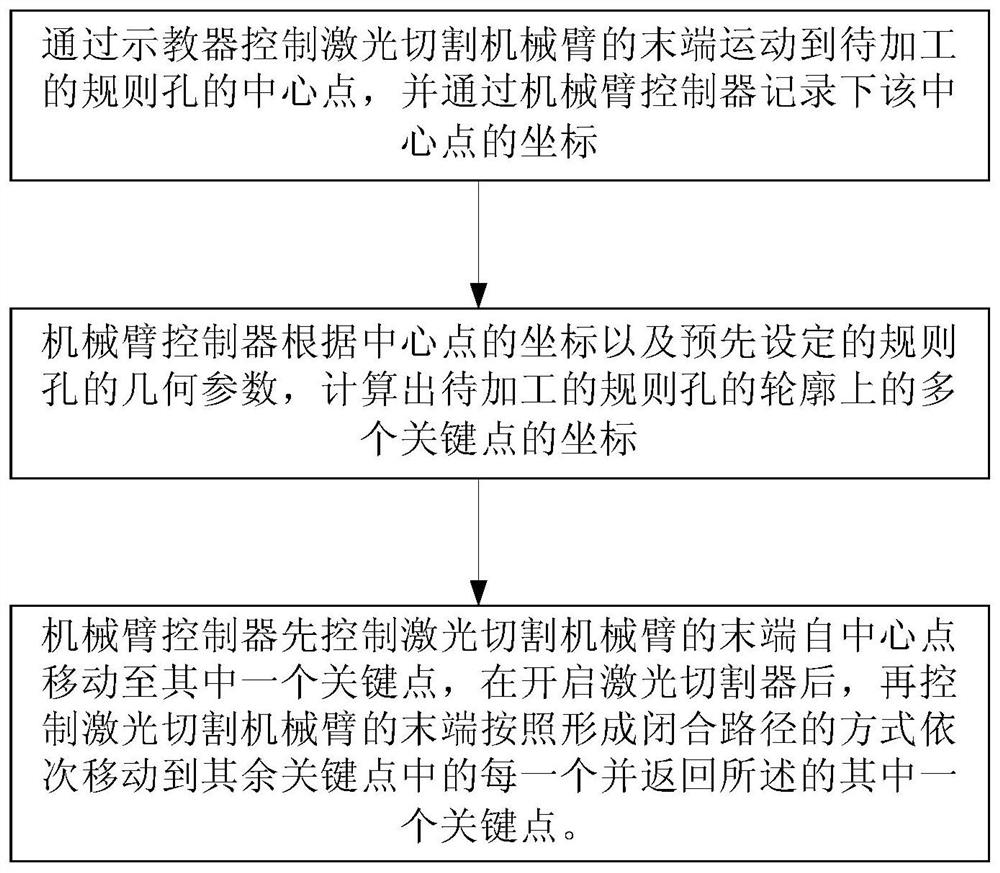

[0015] see figure 1 . According to an embodiment of the present invention, a method for processing regular holes using a laser cutting robot arm includes the following steps:

[0016] Control the end of the laser cutting robot arm to move to the center point of the regular hole to be processed through the teach pendant, and record the coordinates of the center point through the robot arm controller; the end of the laser cutting robot arm is equipped with a laser cutter, which is to be processed The plane where the regular holes are located is perpendicular to the laser emission direction of the laser cutter;

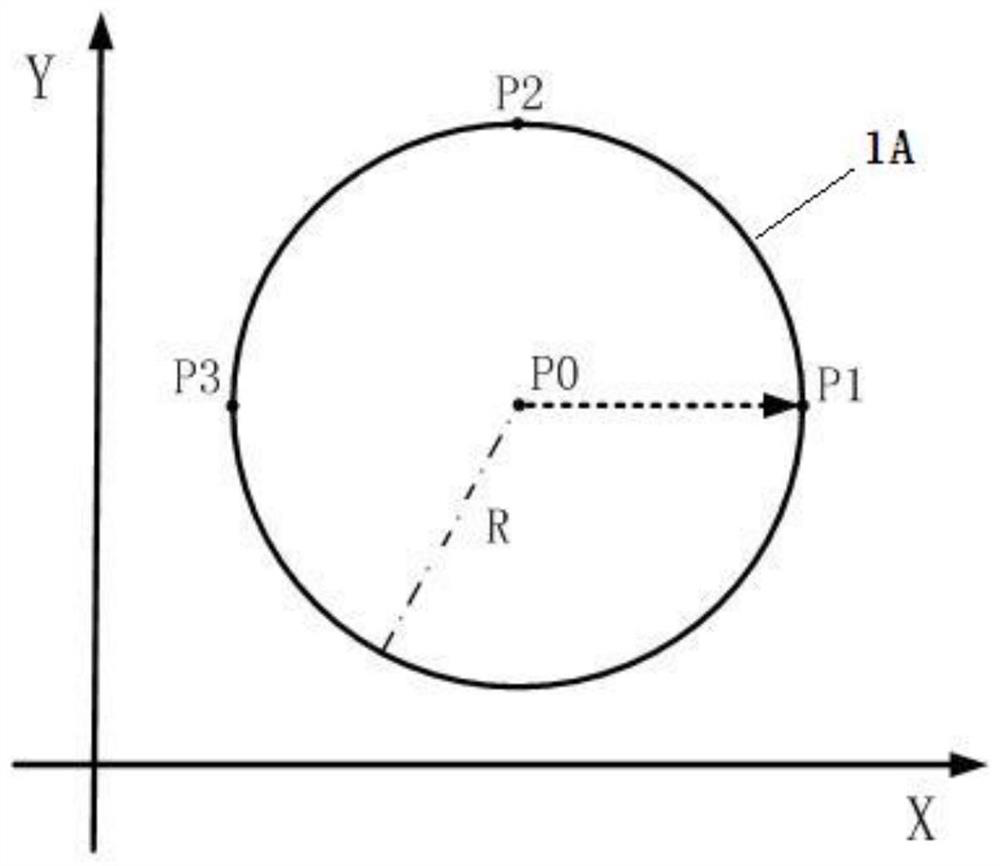

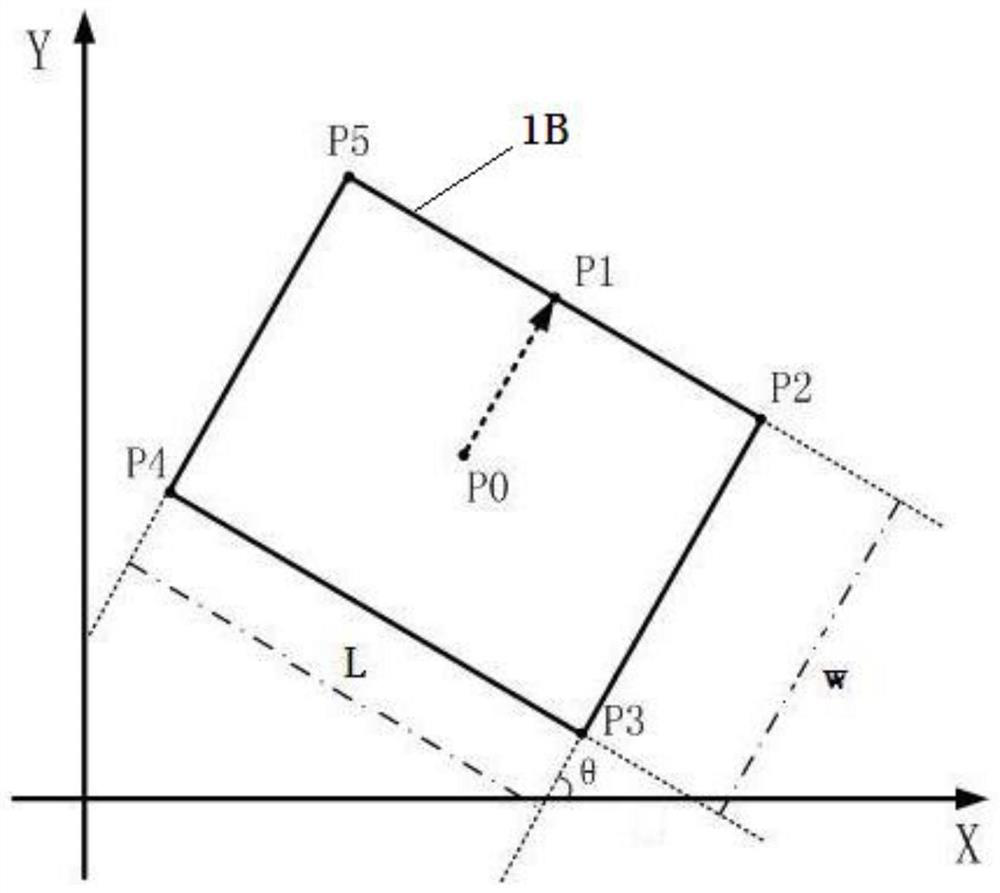

[0017] The robotic arm controller calculates the coordinates of multiple key points on the contour of the regular hole to be processed according to the coordinates of the center point and the preset geometric parameters of the regular hole;

[0018] The robotic arm controller first controls the end of the laser cutting robotic arm to move from the center point to one o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com