A processing mold platform for prefabricated wall panels

A prefabricated wallboard and mold table technology, applied in the direction of manufacturing tools, mold fixtures, mold auxiliary parts, etc., can solve problems such as increasing the labor intensity of workers, unable to ensure the absolute level of the ground, and inconvenient wallboard processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

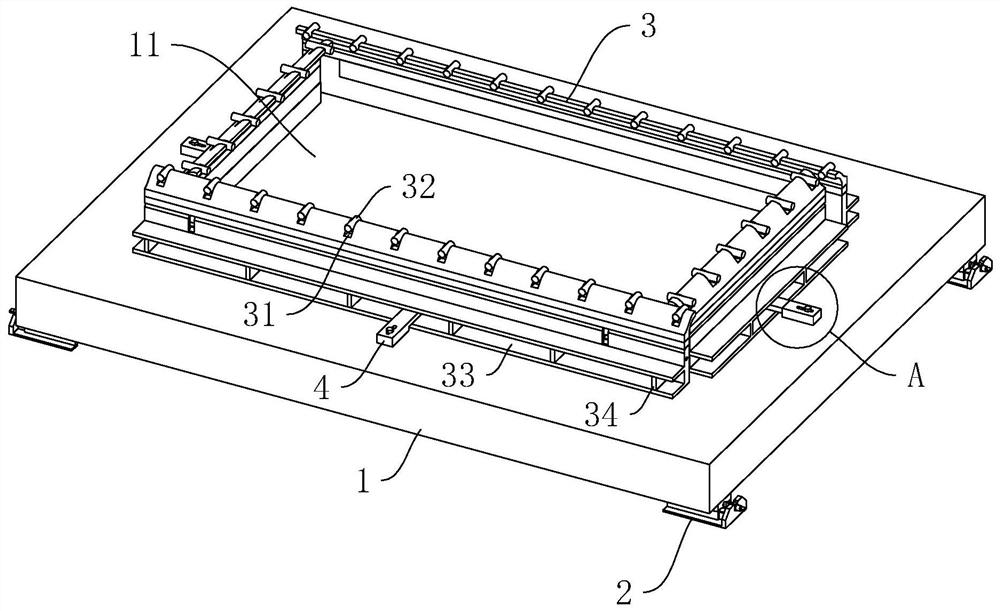

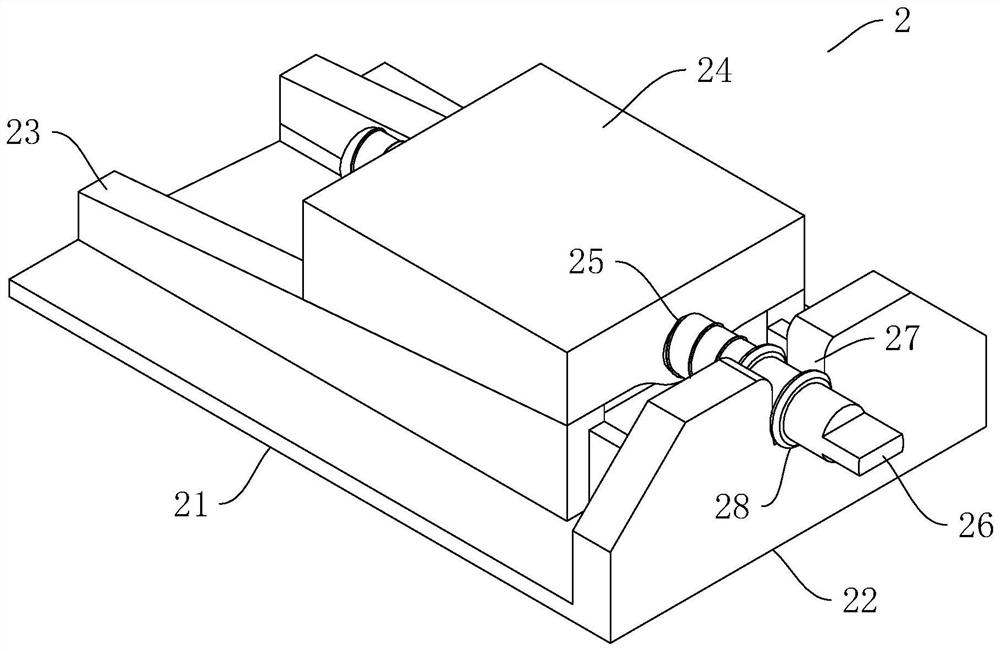

[0036] like figure 1 As shown, a processing mold table for prefabricated wall panels includes a base 1 and a workbench 11 horizontally arranged on the upper end surface of the base 1 , and legs 2 are provided around the lower end surface of the base 1 . A plurality of side molding strips 3 are arranged on the workbench 11, and the side molding strips 3 are connected end to end to form a closed loop.

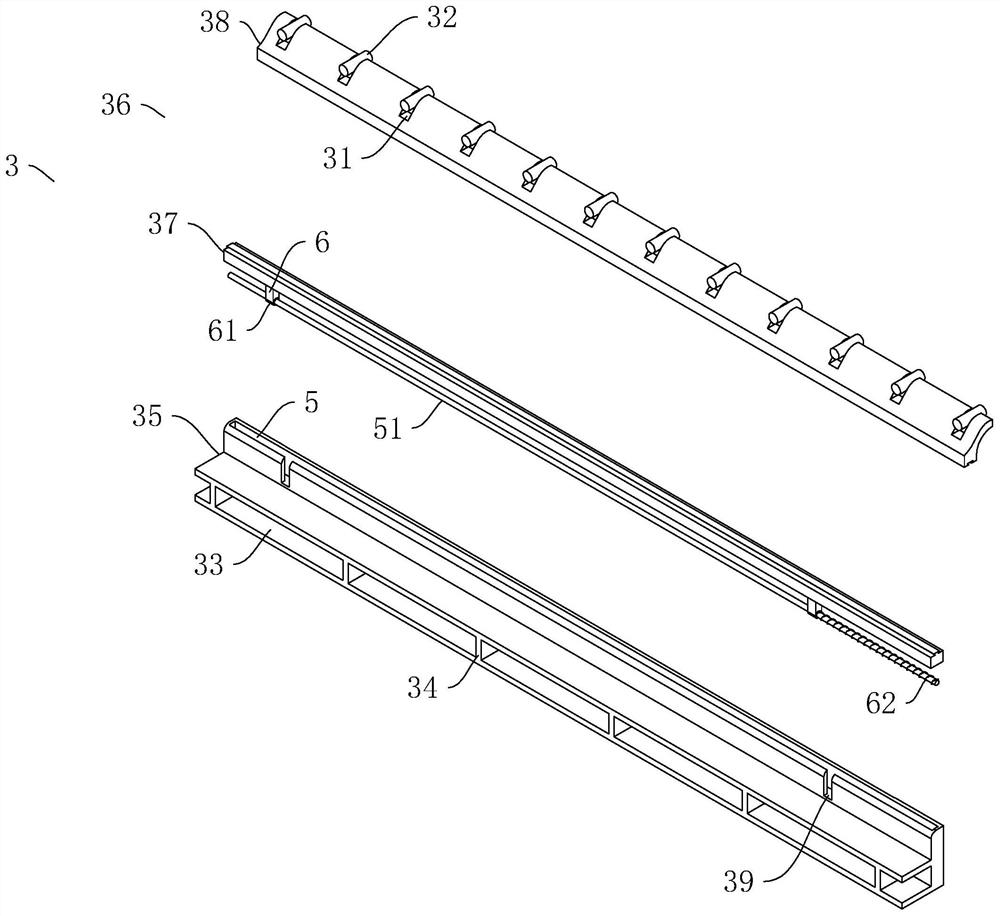

[0037] like figure 1 As shown, the upper end surface of the side mold bar 3 is provided with a number of installation grooves 31, the number of installation grooves 31 are evenly distributed along the length direction of the side mold bar 3, and the installation groove 31 is embedded with a sponge plug 32. A groove 33 runs through the outer wall of the side mold strip 3 along the length direction of the side mold strip 3 , and several reinforcing ribs 34 are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com