A kind of heat-resistant coating and preparation method thereof

A technology of heat-proof coating and heat-proof coating, applied in the direction of coating, etc., can solve the problems of peeling, ablation, cracking, etc., and achieve the effect of excellent heat-proof performance, simple process and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

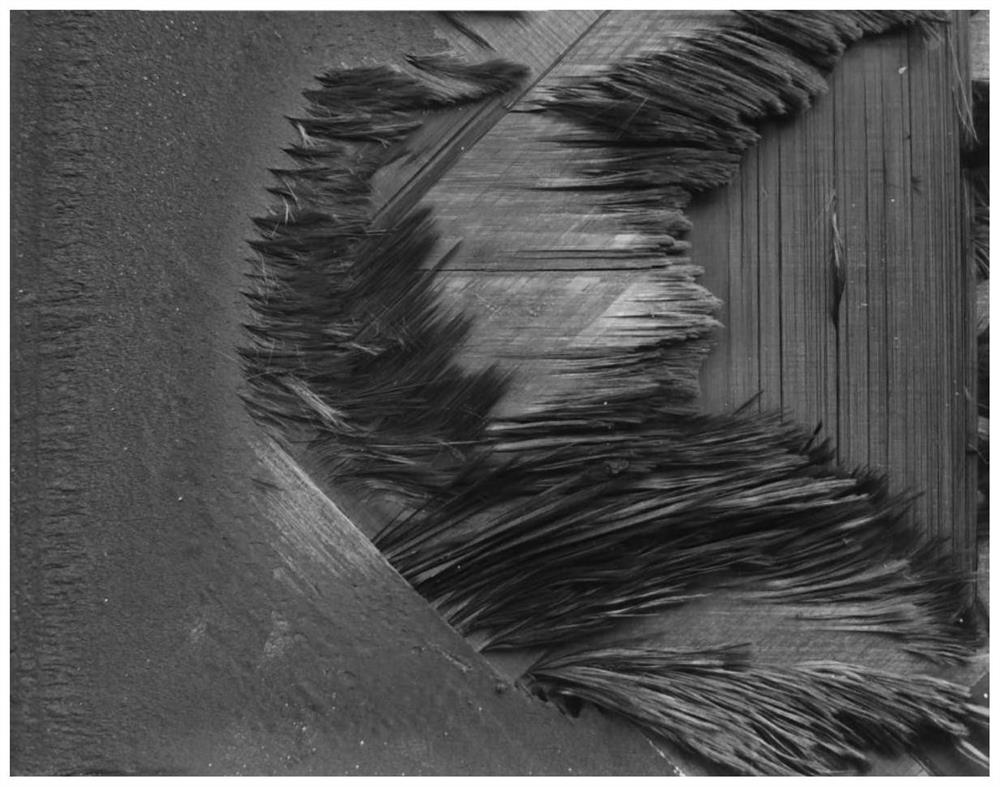

Image

Examples

preparation example Construction

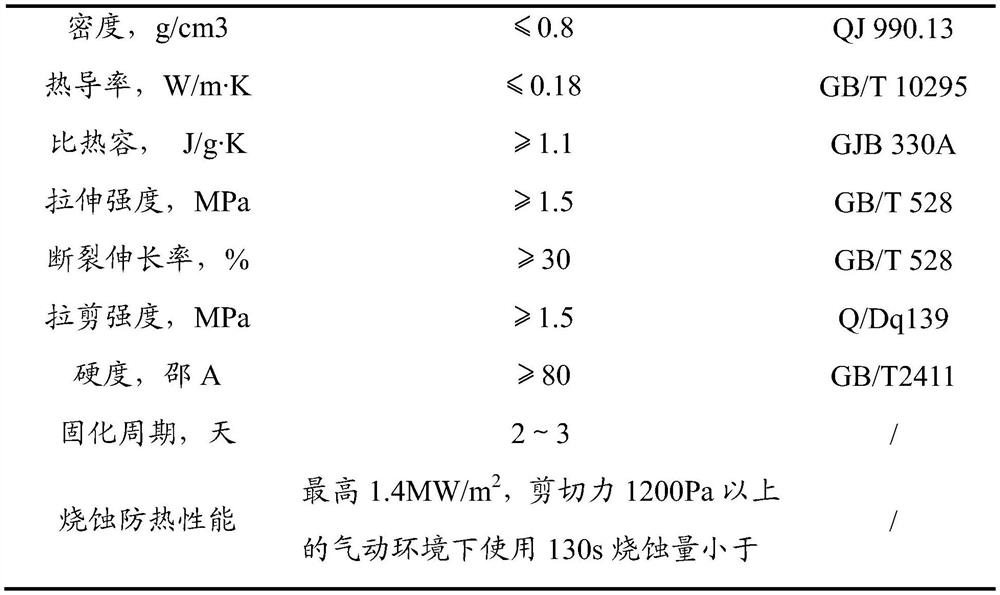

[0053] A kind of preparation method of high shear resistance lightweight heat-resistant coating of the present invention comprises the following steps:

[0054] (1) Mix and disperse vulcanized silicone rubber, reinforcing filler, high-temperature-resistant filler, reinforcing fiber, heat-insulating filler, crosslinking agent and thinner evenly to obtain heat-resistant coating A;

[0055] The mass ratio of each component is: 100 parts of room temperature vulcanized silicone rubber, 10 to 40 parts of reinforcing filler, 35 to 70 parts of high temperature resistant filler, 14 to 41 parts of reinforcing fiber, 16 to 52 parts of heat insulating filler, crosslinking agent 1.8 to 6.2 parts, 32 to 104 parts of diluent.

[0056] (2) Mix the catalyst and vinyl silicone oil at a mass ratio of 1:10-20, and stir evenly to obtain heat-resistant coating B.

[0057] (3) Use thinner to adjust the viscosity of heat-resistant coating A to 18-25s (coating 4 viscosity), according to the mass rati...

Embodiment 1

[0080] (1) Add 100g of vinyl-terminated methylphenyl silicone rubber and 10g of white carbon black to the material tank of the kneader, start the kneader and disperse for more than 5min at a speed of 500r / min until the mixture is translucent, Preparation of mixture A1;

[0081] (2) Add 10 g of zirconia powder, 20 g of zinc phosphate, and 5 g of yttrium oxide to mixture A1, and start the kneader to disperse for more than 10 minutes at a rotating speed of 500 r / min to obtain mixture A2;

[0082] (3) Add 20 g of glass fiber to mixture A2, and grind it 4 to 5 times on a three-roll mill to obtain mixture A3;

[0083] (4) Add 20g of hollow glass microspheres, 5g of cork powder, 2g of hydrogen-containing silicone oil, and 40g of xylene to mixture A3, and disperse for more than 5min at a speed of not less than 100r / min in a high-speed stirring method to obtain heat-resistant Coating A component;

[0084] (5) Take 10g of chloroplatinic acid and 100g of vinyl silicone oil, mix and sti...

Embodiment 2

[0090] (1) Add 100g of vinyl-terminated methyl silicone rubber and 20g of calcium carbonate to the material tank of the kneader, start the kneader and disperse for more than 5min at a speed of 500r / min until the mixture is uniform white paste transparent , to prepare mixture A1;

[0091] (2) Add 15 g of talcum powder, 15 g of zinc borate, and 10 g of iron oxide to mixture A1, and start the kneader to disperse for more than 10 minutes at a rotating speed of 500 r / min to obtain mixture A2;

[0092] (3) Add 20 g of chopped carbon fiber to the mixture A2, and grind it on a three-roll mill for 4 to 5 times to prepare the mixture A3;

[0093] (4) Add 15g of hollow glass microspheres, 5g of hollow phenolic microspheres, 4g of hydrogen-containing silicone oil, and 50g of butyl acetate into the mixture A3, and disperse for more than 5min at a speed of not less than 100r / min in a high-speed stirring method to prepare Obtain heat-resistant coating A component;

[0094] (5) Take 10g of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com