Electroplating apparatus

A technology of electroplating equipment and electroplating solution, which is applied to electrodes, electrolysis process, electrolysis components, etc., can solve the problems of reduced appearance of electroplating products, insufficient surface of electroplating workpieces, and inability to meet the quality requirements of electroplating products, and achieves good metal texture. with glossy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to fully understand the purpose, features and effects of the present invention, the present invention will be described in detail through the following specific embodiments and accompanying drawings, as follows.

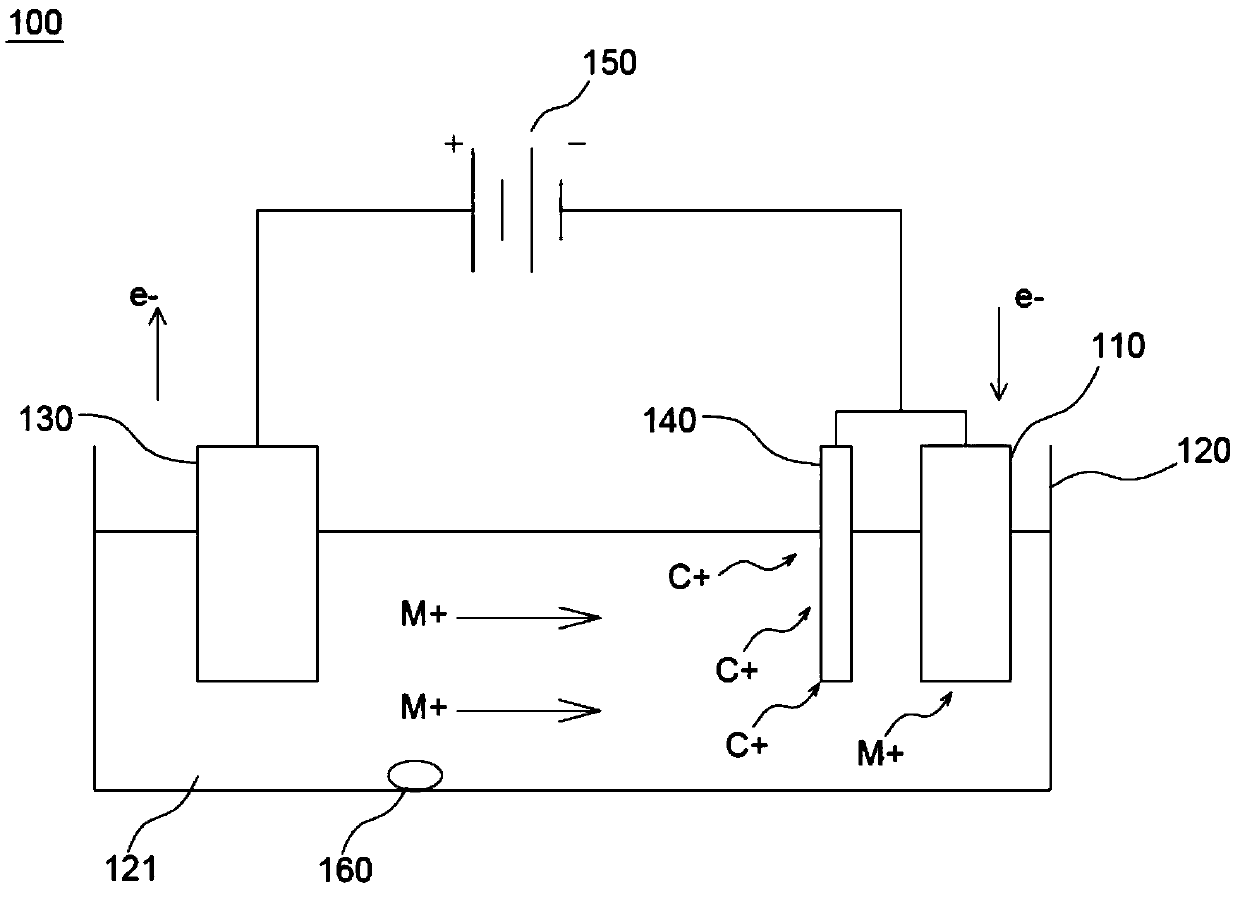

[0030] Please refer to figure 1 Shown is a schematic diagram of an electroplating device according to an embodiment of the present invention. The electroplating device 100 of the present invention is suitable for an electroplating process with an anode, and performs electroplating on a workpiece 110 to be electroplated. The electroplating equipment 100 of this embodiment includes an electroplating tank 120, a target material 130, an adsorption member 140, and a power supply 150. The electroplating solution 121 is injected and stored in the electroplating tank 120 of the electroplating equipment 100, and the workpiece 110 to be electroplated and the target material 130 are placed in the electroplating tank 120 , so that at least a part of the workpiece...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com