Construction method for increasing one-time qualification rate of pile foundation in karst or broken zone area

A construction method and broken zone technology, which is applied in foundation structure engineering, sheet pile walls, buildings, etc., can solve the problems of easy cracks and grout leakage, concrete overfilling and shrinkage, and strong concealment, so as to improve the qualified rate of hole formation , The construction quality is stable and the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

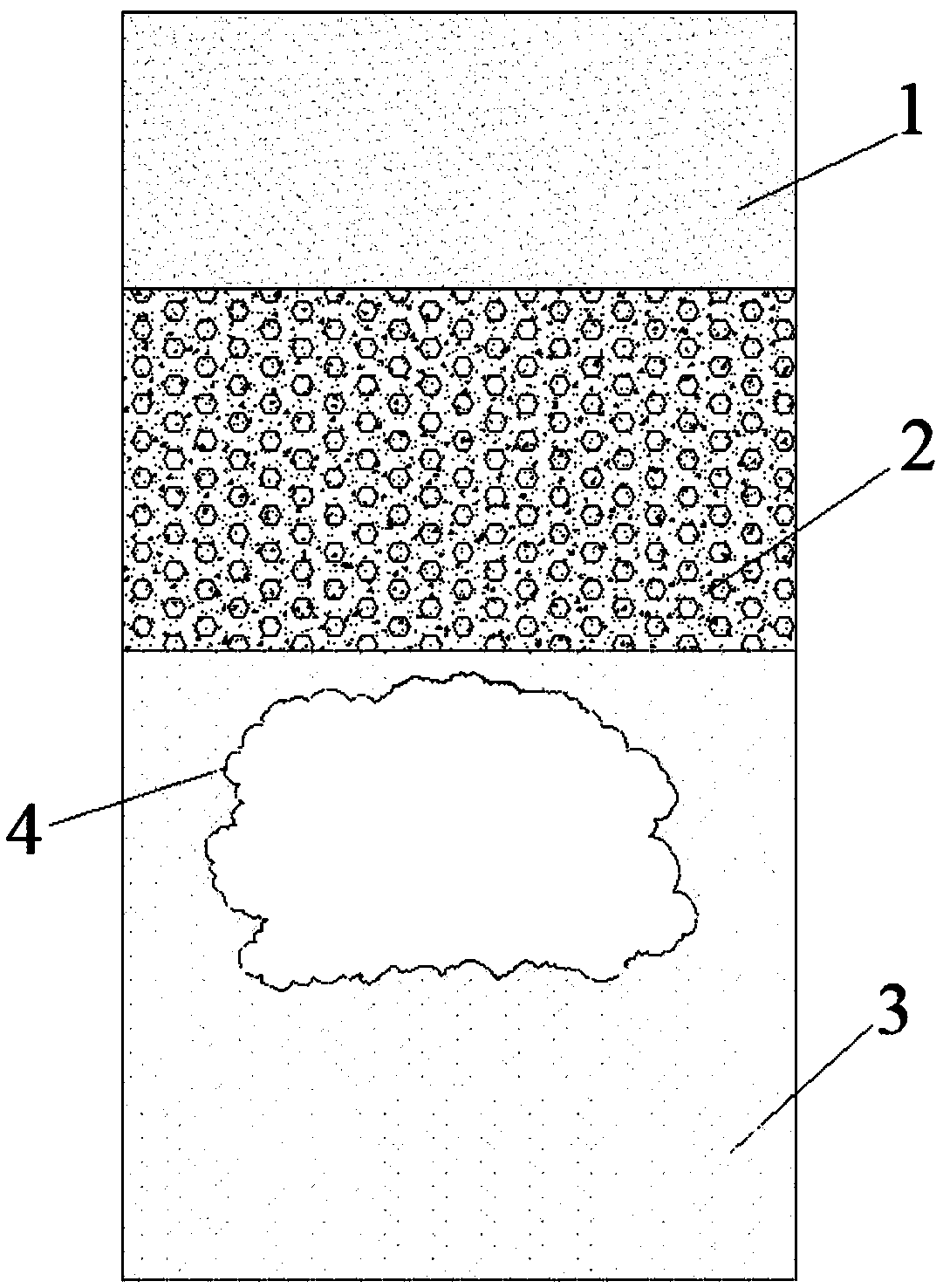

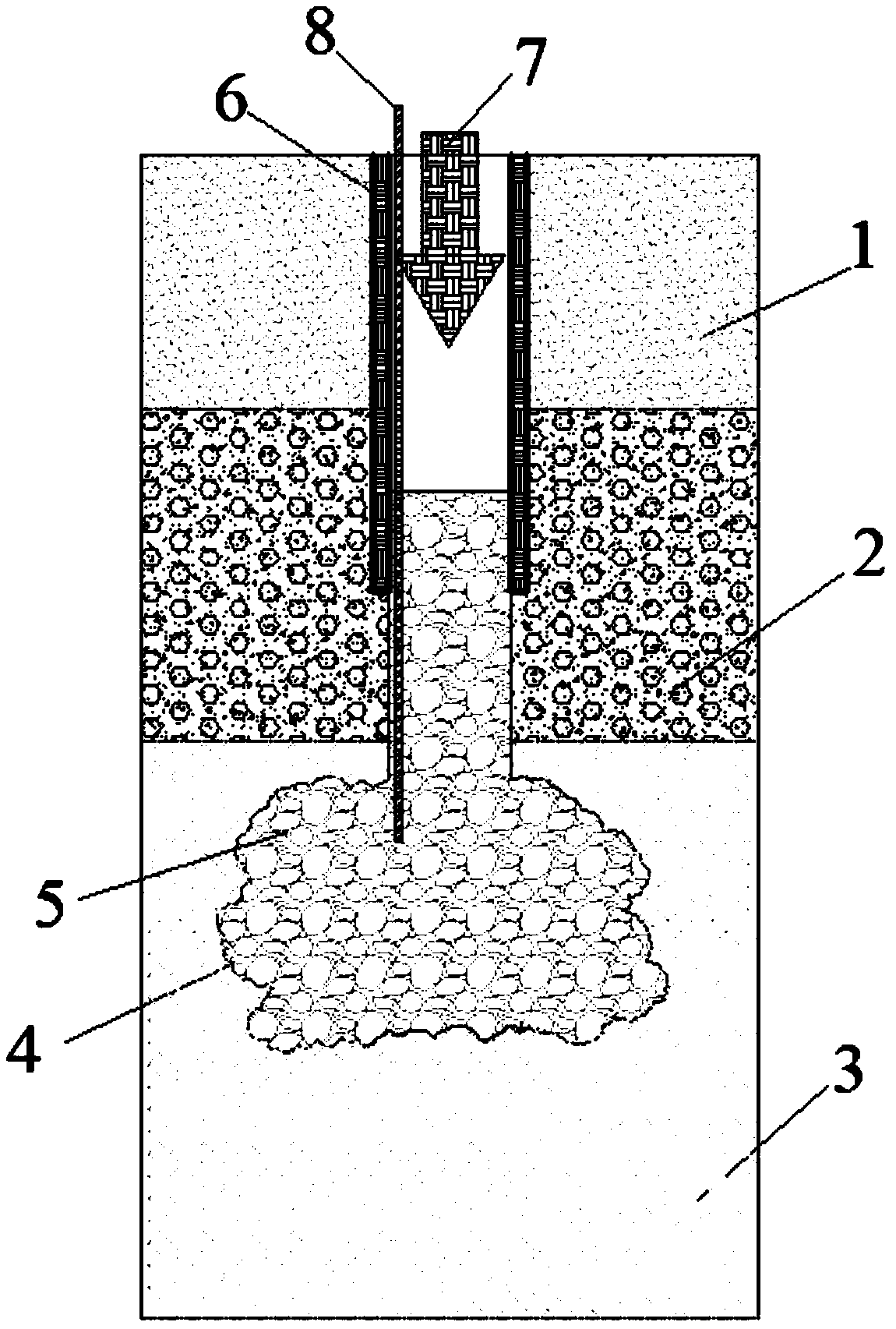

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, taking karst areas as an example.

[0028] The construction method for improving the qualified rate of primary hole formation of pile foundations in karst areas includes the following steps:

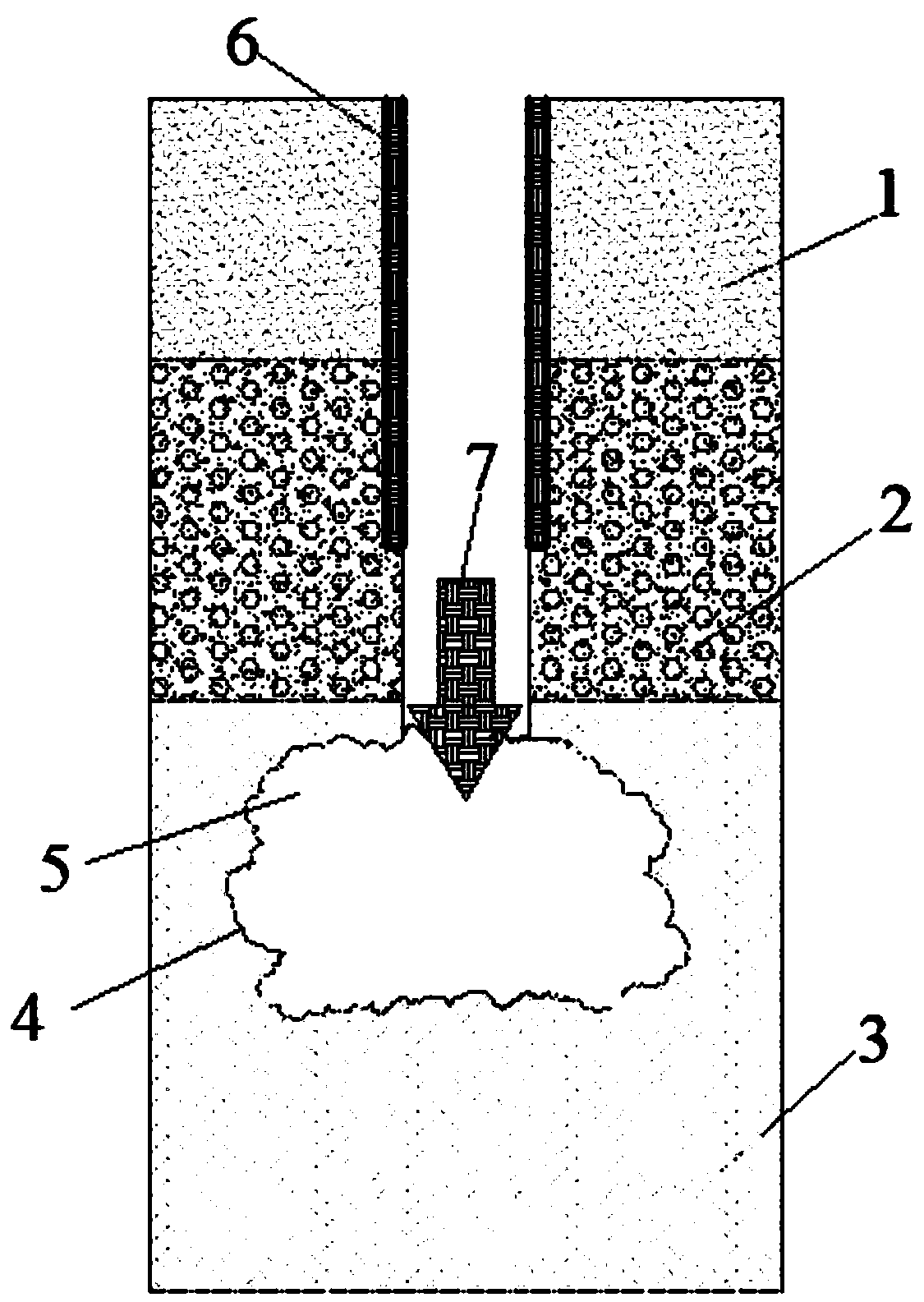

[0029] Step 1: measure and set out the hole position of the pile foundation, and make a steel casing 6 at the same time. The steel casing 6 is made of a steel plate with a thickness of 4-8mm, and the inner diameter D is 20cm larger than the pile diameter d, that is, =d +20cm;

[0030] Step 2: Bury the steel casing 6 at the designated hole position, and control the verticality deviation of the steel casing through the guide facilities to be no more than 1 / 250; not less than 1.0m in cohesive soil, and not less than 1.5m in sandy soil.

[0031] Step 3: Use the rotary drill to drill to the bottom of the clay layer 1, enter the hard plastic soil layer 2 and replace it with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com