Vehicle rear independent main deceleration assembly

A main reducer, an independent technology, applied in the direction of differential transmission, gear transmission, belt/chain/gear, etc., can solve the difficulty of adjusting the tooth side clearance, reduce the impact resistance of the differential case, and difficult to control And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

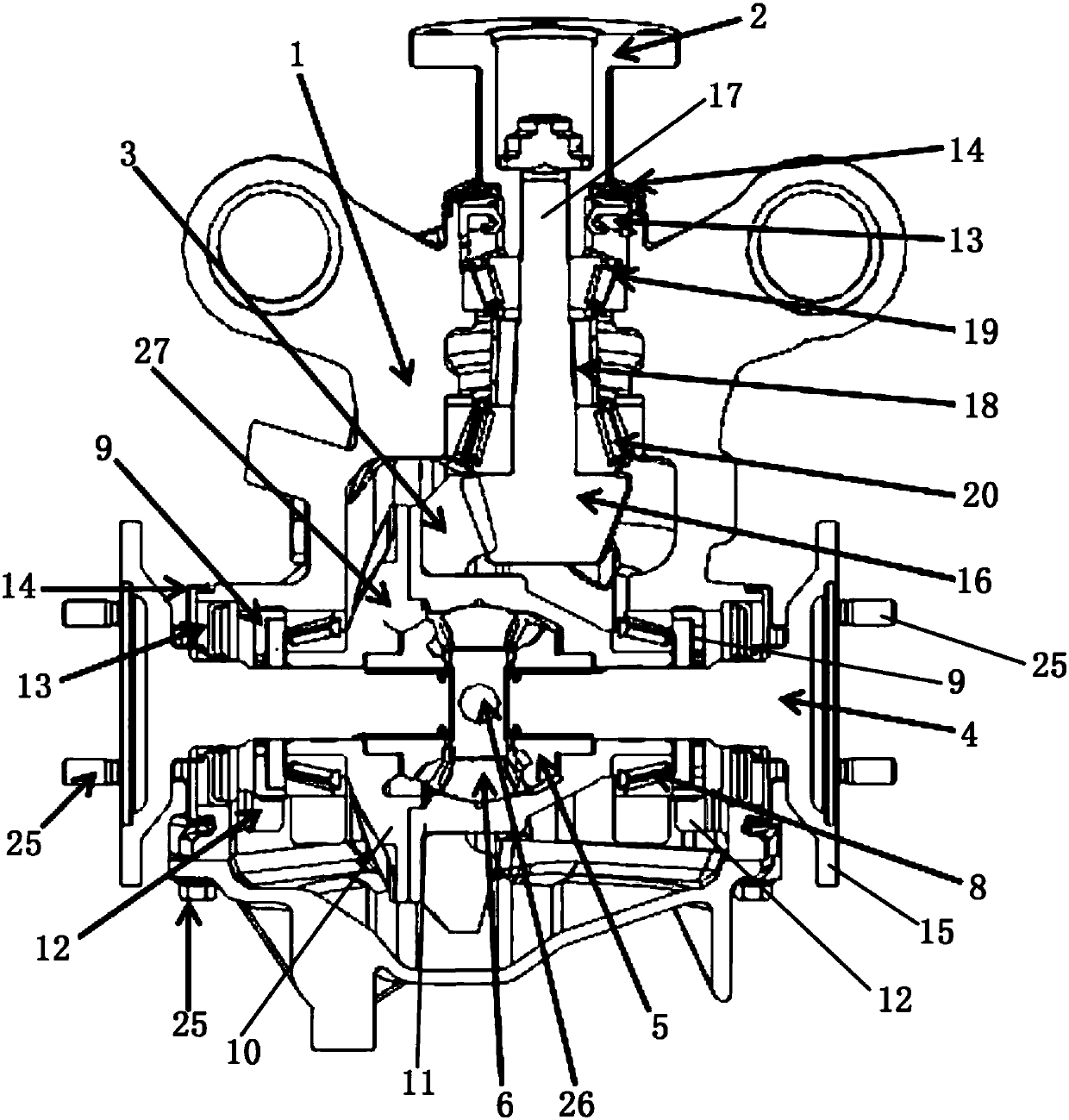

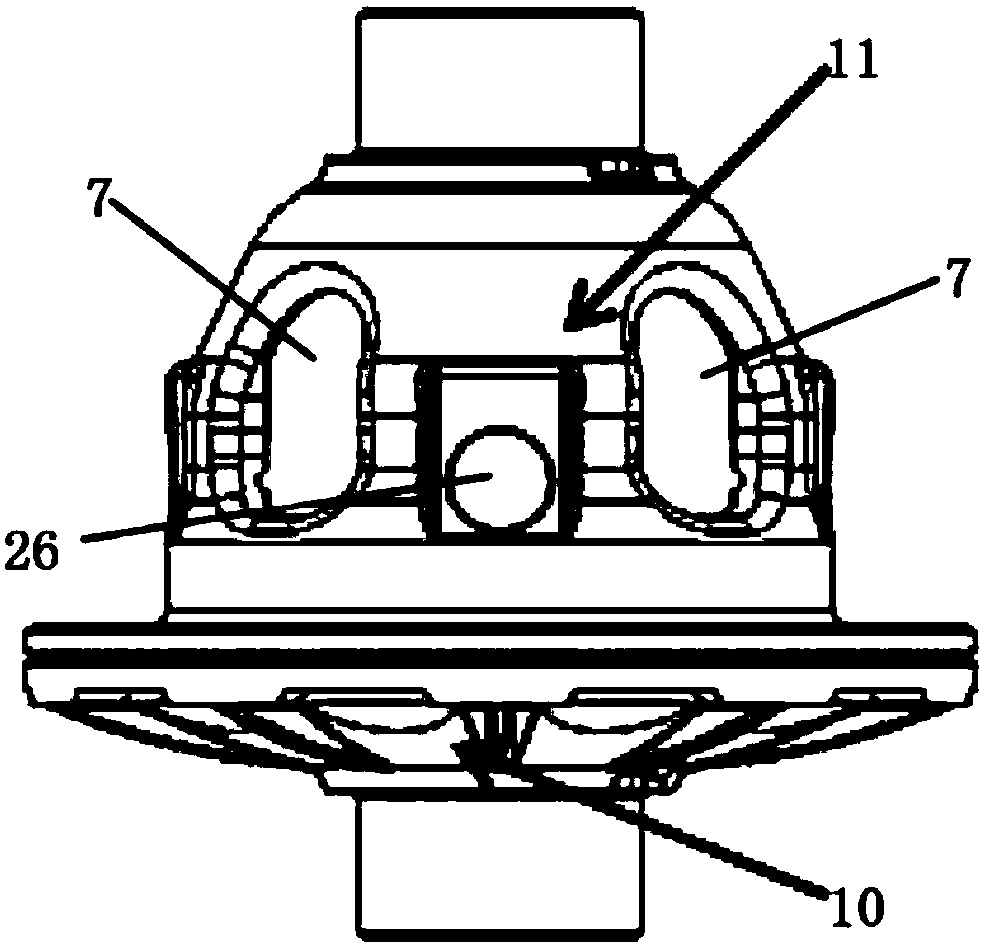

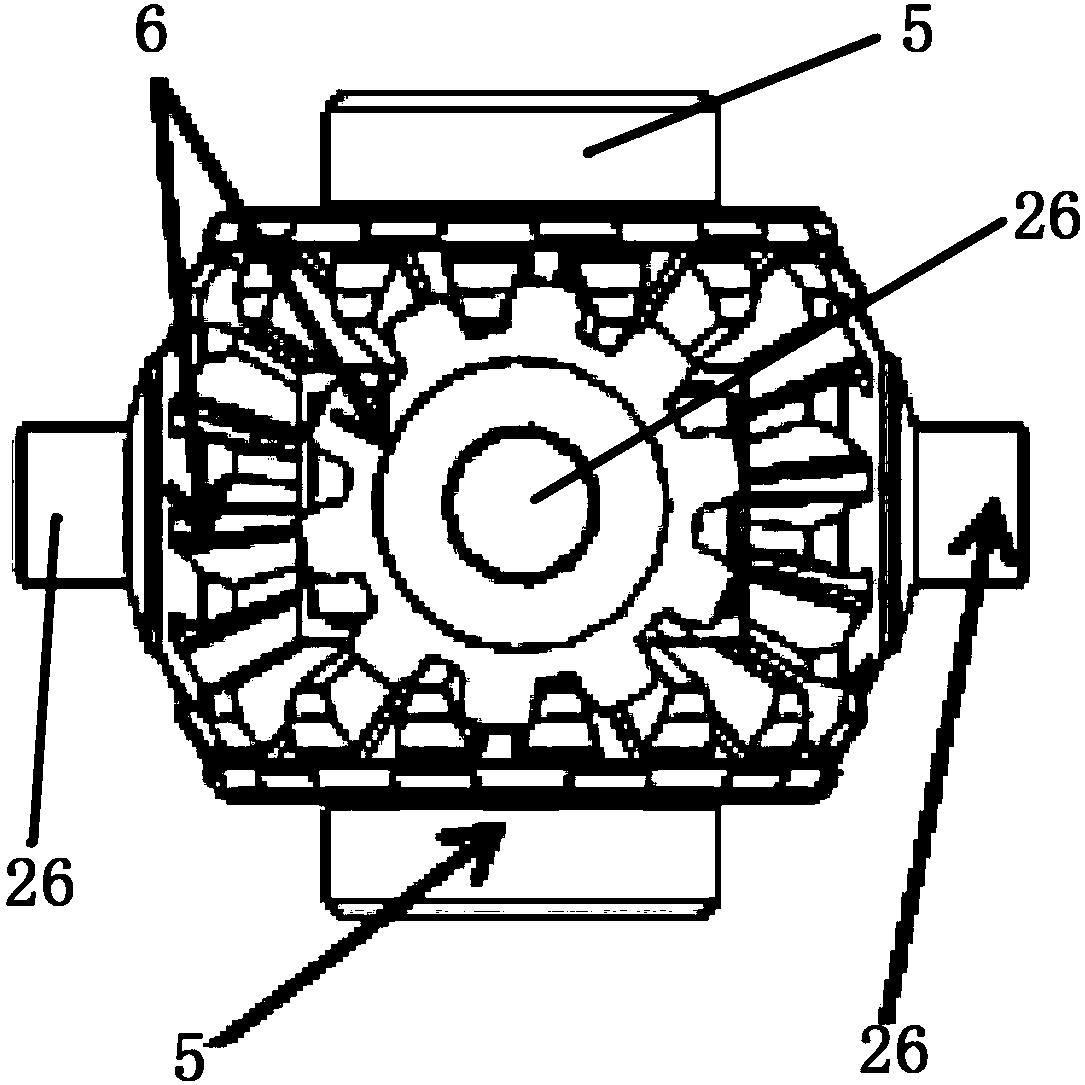

[0031] The following with attached Figure 1 to Figure 6 An automobile rear independent final reducer assembly of the present invention is further described in detail.

[0032] An automobile rear independent main reducer assembly of the present invention, please refer to Figure 1 to Figure 6The relevant figures in the figure include the connecting flange 2, the final reducer housing 1, the main gear set in the final reducer housing 1, the secondary gear 3, the differential assembly and the The differential half shaft 4 on the left and right sides of the differential assembly, the connecting flange 2 is fixed to the main tooth, the main tooth is a bevel gear, and the passive tooth 3 is fixed to the main tooth , the central axes of the main teeth and the passive teeth 3 are perpendicular to each other, and the differential assembly includes a differential case, side gears 5 located at the left and right ends of the differential case, and Four planetary gears 6 between the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com