No-clearance rectilinear motion actuator with multiple-stage planetary roller screw pair

A technology of linear motion and planetary rollers, applied in transmission devices, belts/chains/gears, mechanical equipment, etc., can solve problems such as reducing motion stability and running accuracy, reducing motion efficiency, increasing mechanism wear, etc., to achieve structural Compact, reduce processing difficulty, ensure the effect of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

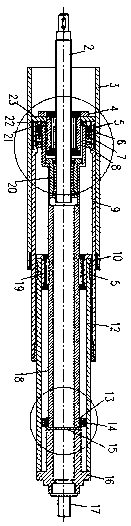

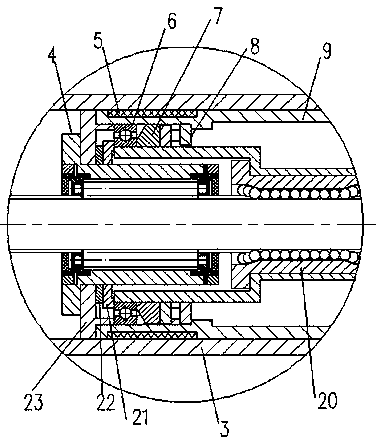

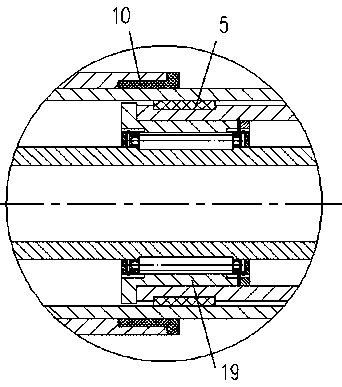

[0017] like Figure 1 to Figure 5 As shown, a multi-stage planetary roller screw pair gapless linear motion actuator of the present invention includes a primary screw 2, an actuator housing 3, a first roller nut 4, a sliding sleeve 5, and a first deep groove Ball bearing 6, first-stage housing 9, second-stage housing 12, sleeve 16, push rod 17, hollow screw 18, second roller nut 19, rolling spline sleeve 20, gland 21 and limit Sleeve 23, the first roller nut 4 is threaded on the primary screw 2, the sliding sleeve 5 is sleeved on the outer wall of the first-stage housing 9, and the outer wall of the sliding sleeve 5 is slidably connected to the inner wall of the actuator housing 3 superior. The left end of the hollow screw 18 is rotatably supported on the inner wall of the first-stage housing 9 through the first deep groove ball bearing 6, the gland 21 and the limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com