Public building kitchen oil smoke exhausting pipeline system

A pipeline system and public building technology, which is applied in the field of public building kitchen oil fume exhaust pipeline system, can solve the problems of negative impact on the city image, difficult to clean, ugly appearance, etc., and achieve the effect of improving the city image, reducing pollution, and simplifying the installation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

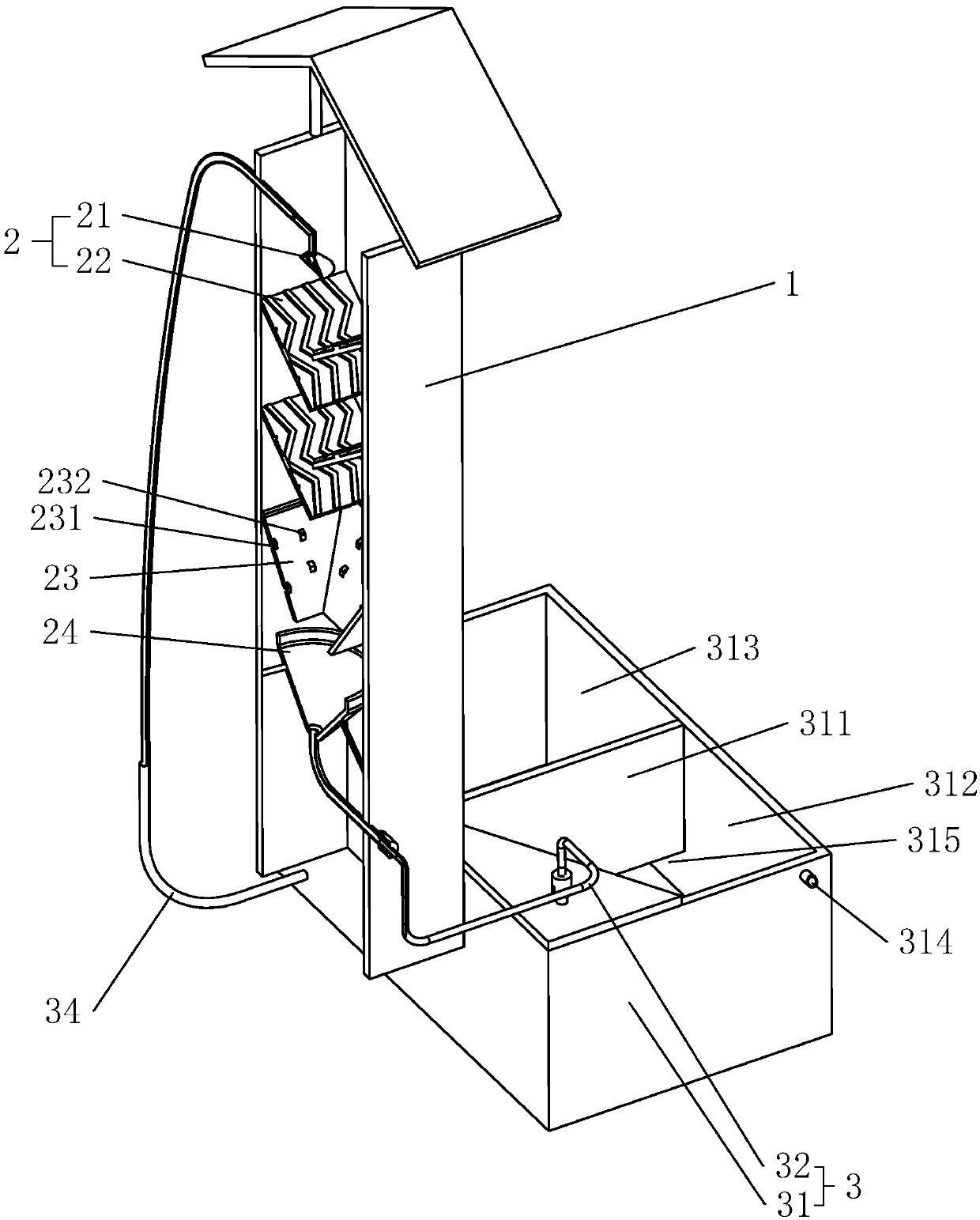

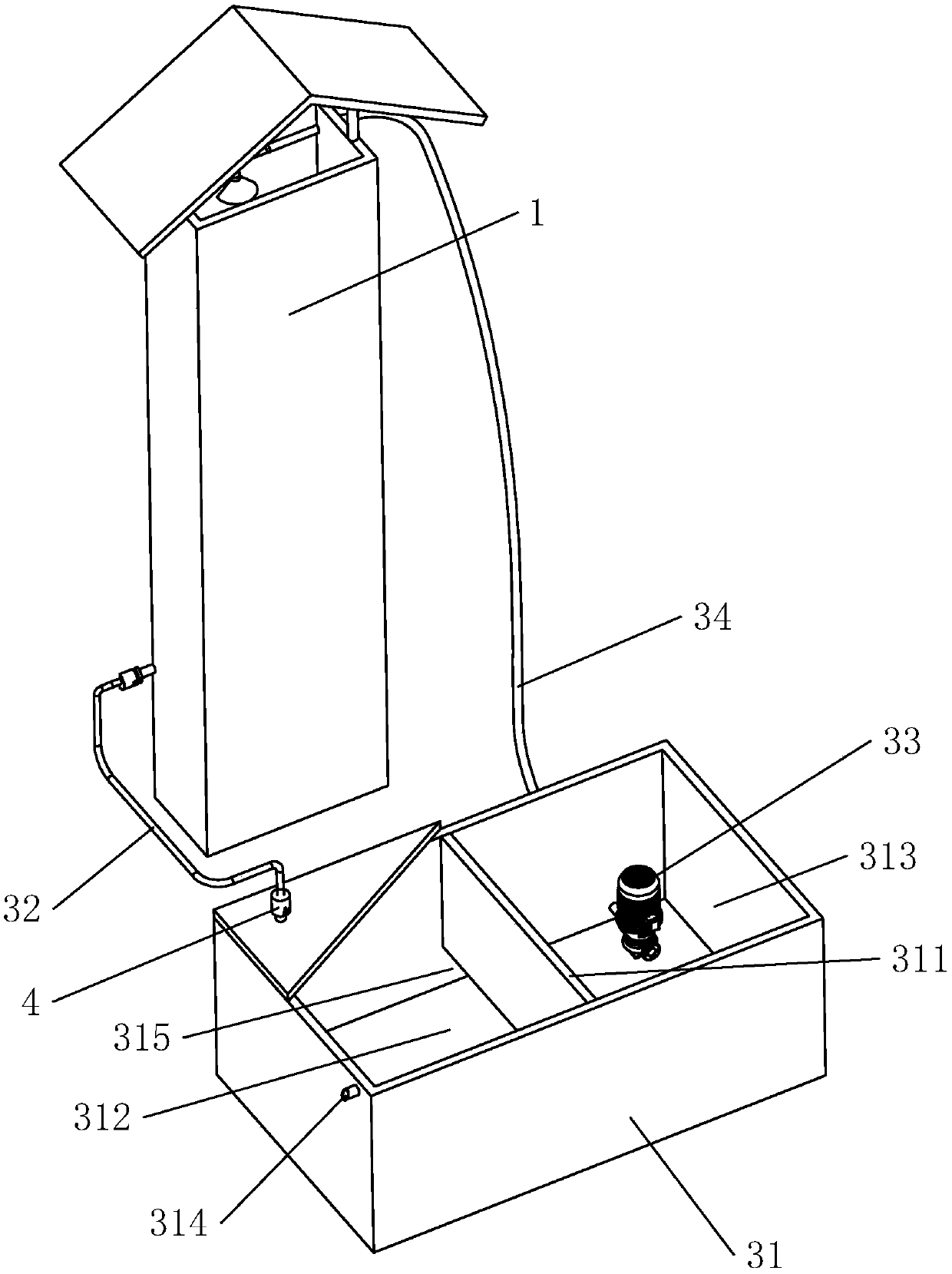

[0035] Such as figure 1 As shown, a cooking fume exhaust pipeline system in a public building includes a pipeline main body 1 and a fume filter device 2. The pipeline main body 1 is used to be installed on the outer wall of the building, and is mainly connected with the kitchen range hood pipeline, and guides The fume from the range hood is discharged into the upper atmosphere.

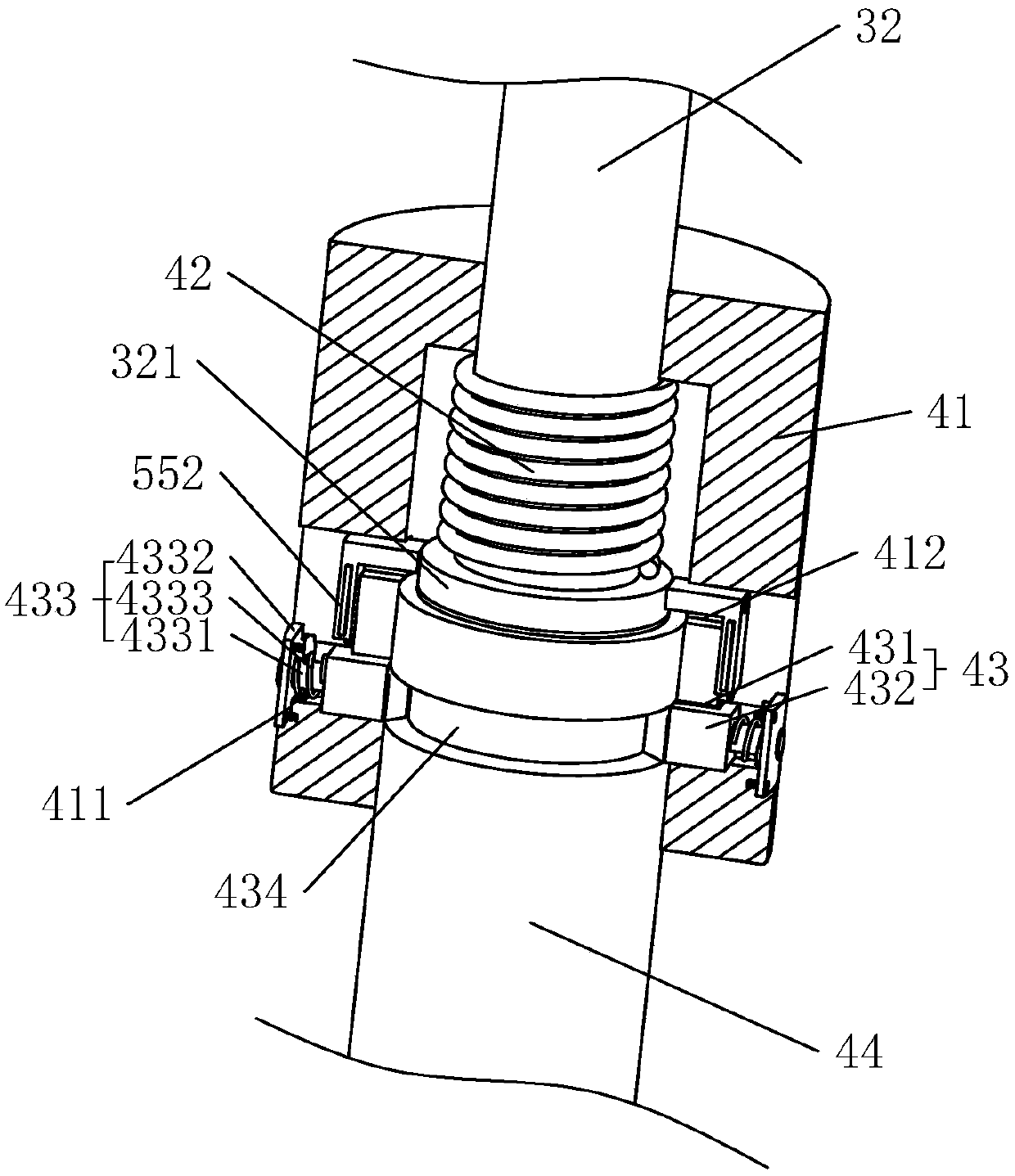

[0036] Oil fume filter device 2 spray head 21, liquefaction plate 22, water diversion bucket 23, and dirt bucket 24, the spray head 21 is fixed in the pipeline main body 1, and is close to the gas outlet of the pipeline main body 1; the liquefaction plate 22 is provided with at least two sets , the number of each group is more than two, the liquefaction plate 22 is fixed on the inner wall of the pipeline main body 1, and is located under the sprinkler head 21; two groups of liquefac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com