Reciprocating sealing element detection test bed and reciprocating sealing detection method

A reciprocating motion and sealing detection technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., to achieve the effects of high detection reliability, simple structure, and verification of sealing pressure capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

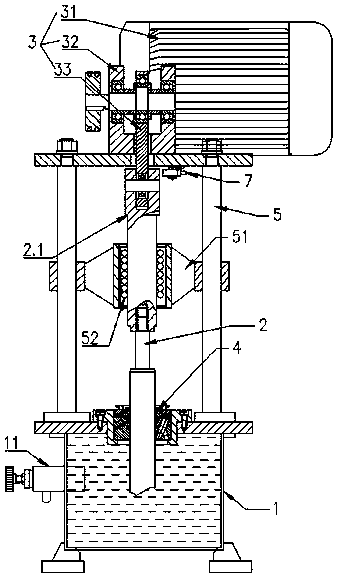

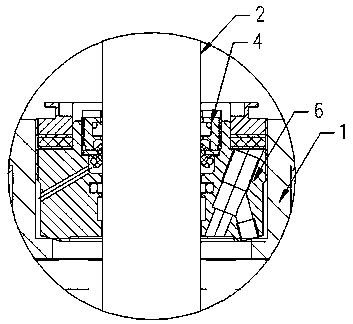

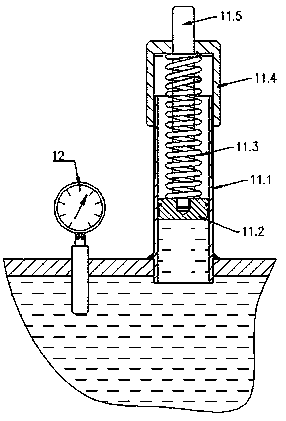

[0027] Combine below Figure 1 to Figure 4 Embodiments of the present invention are described in detail.

[0028] The reciprocating motion seal detection test bench is characterized in that it includes a fuel tank 1 filled with hydraulic oil, a piston rod 2 arranged along the central axis of the fuel tank 1 with one end extending into the fuel tank 1, and a piston rod 2 for driving the piston rod 2 to reciprocate along the central axis of the fuel tank 1 The transported electric eccentric wheel assembly 3 and the sealing test piece 4 are installed between the fuel tank 1 and the piston rod 2 to form a sealing friction pair to seal the fuel tank 1.

[0029] In the reciprocating motion seal test bench shown in the figure, one end of the piston rod 2 is inserted into the oil tank 1, and the oil tank is sealed by forming a sealing friction pair between the sealing test piece 4 and the piston rod 2, and the oil pressure shock absorber The setting structure of the guide support sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com