Leakage current detecting device

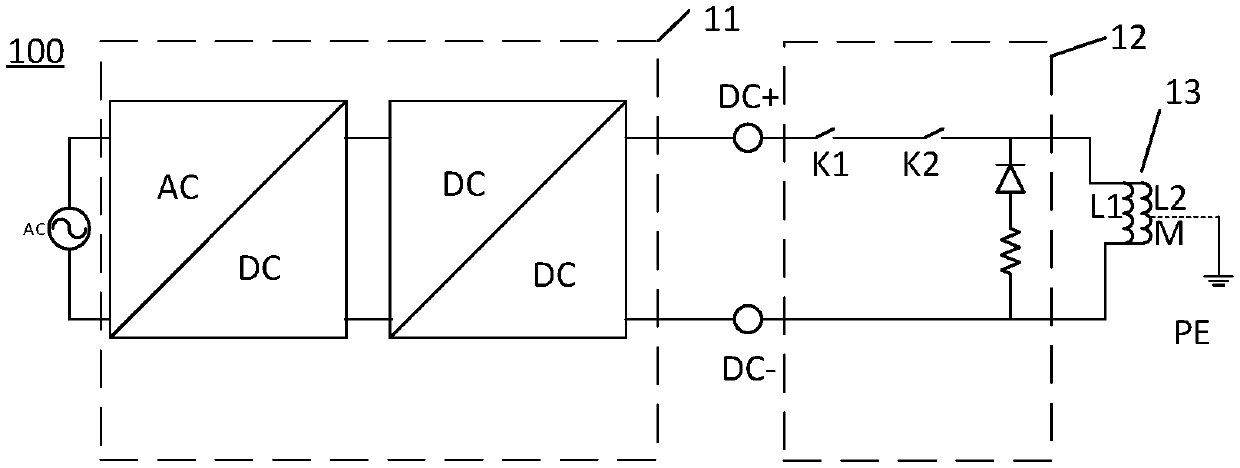

A technology of leakage current detection and resistance, which is applied in the field of elevators, can solve the problems of unbalanced current, high cost, and out-of-synchronization of brake coils, etc., and achieve the effect of using fewer components, simple scheme, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

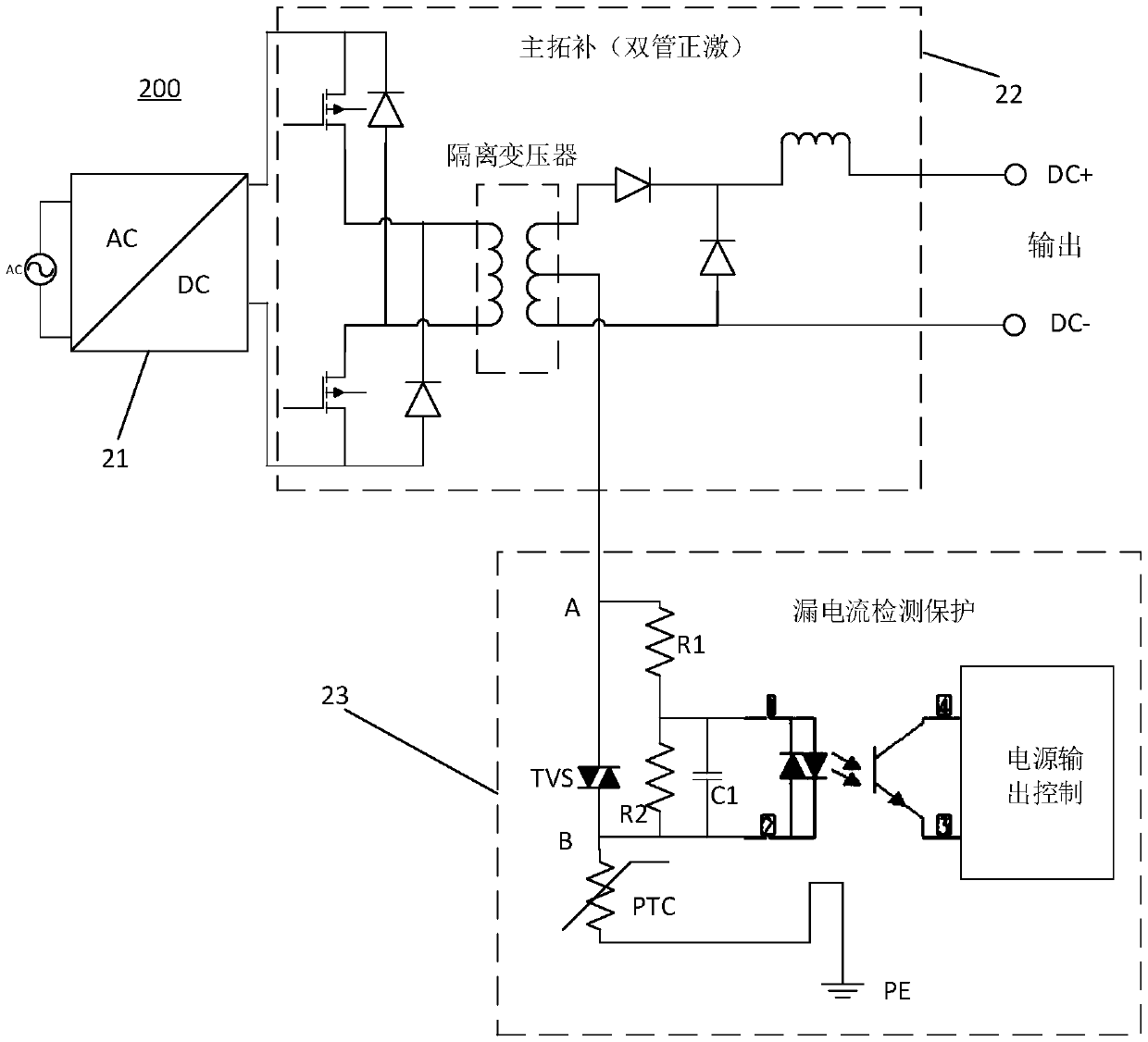

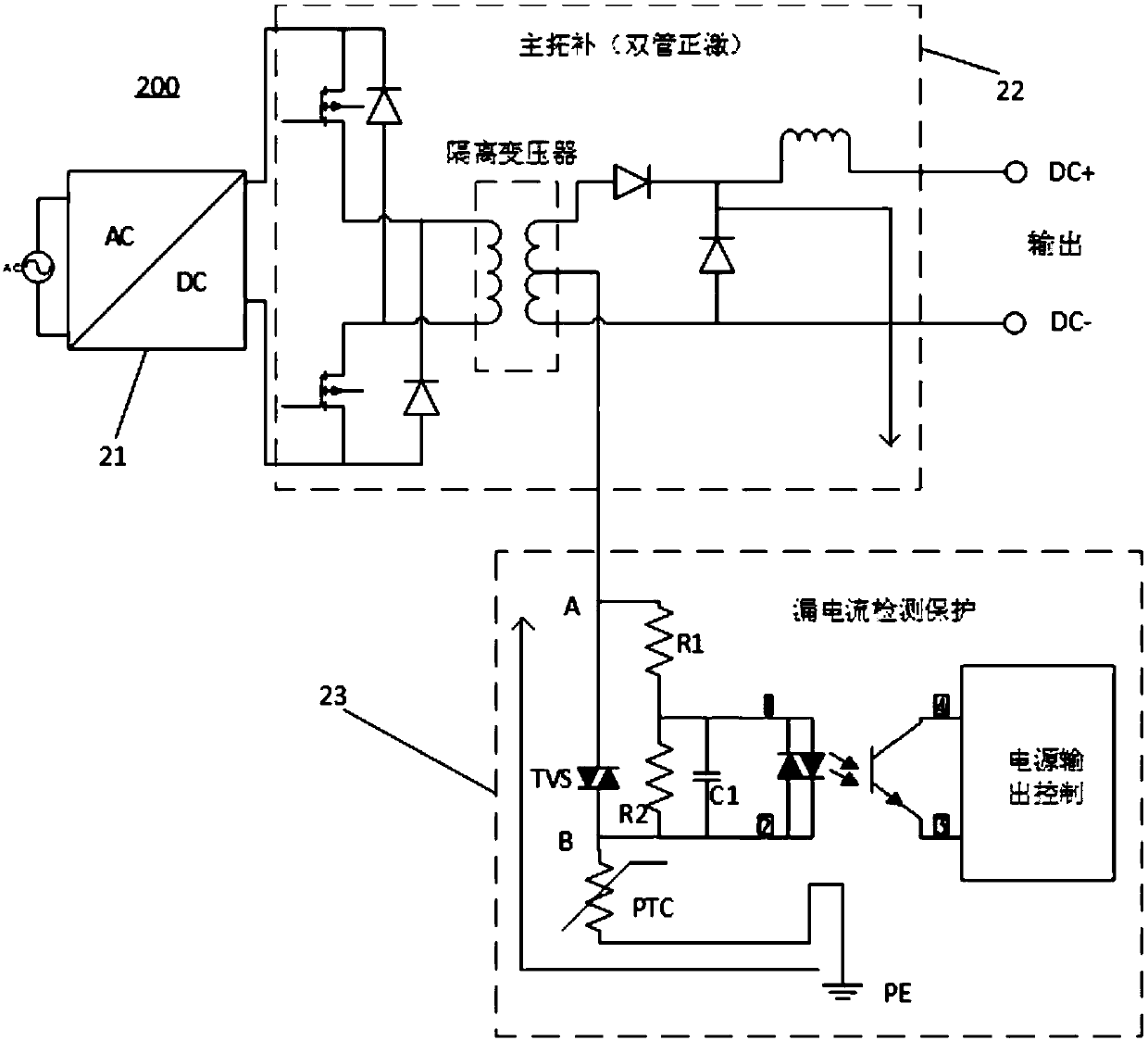

[0025] figure 2 is a schematic circuit diagram of a leakage current detection device provided by an embodiment of the present invention. see figure 2 , the leakage current detection device, including: the middle tap of the secondary winding of the isolation transformer (or the middle tap of the output filter inductor of the non-isolated topology), thermistor PTC, leakage current sampling resistor R2, adjusting resistor R1, bidirectional Transient suppression tube TVS, filter capacitor C1 and bidirectional optocoupler U1, the first end of the bidirectional transient suppression tube TVS is electrically connected to the middle tap of the secondary winding of the isolation transformer, and the second end of the bidirectional transient suppression tube TVS end is electrically connected with the first end of the thermistor PTC, the second end of the thermistor PTC is grounded, the first end of the adjusting resistor RI is connected with the first end of the bidirectional transie...

Embodiment 2

[0032] Figure 4 is a schematic circuit diagram of the leakage current detection device provided by Embodiment 2 of the present invention. This embodiment is optimized on the basis of the foregoing embodiments. Specifically, the leakage current detection device can also be added: a power output control unit, the power output control unit is electrically connected to the secondary side of the bidirectional optocoupler U1, and the power output control unit is used to The detection signal generated by the secondary side of the optocoupler U1 controls the on-off of the power supply.

[0033] When it is detected that the output of the integrated power supply leaks to the ground PE, the leakage detection signal is output in time to control the output of the integrated power supply. When the output part of the integrated power supply brake is leaking, the output of the integrated power supply can be controlled to stop the elevator and prevent the elevator from being dragged. On the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com